Method for manufacturing low-grade coal slurry, device for manufacturing low-grade coal slurry, and gasification system for low-grade coal

A low-grade coal and manufacturing method technology, applied in the direction of manufacturing combustible gas, gasification process, granular/powdered fuel gasification, etc., can solve problems such as energy efficiency decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

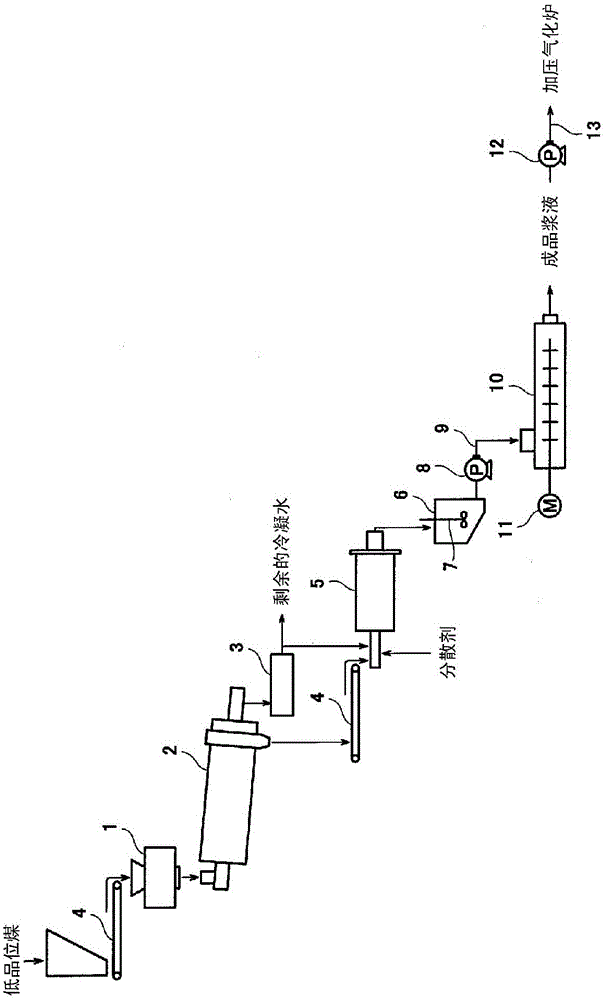

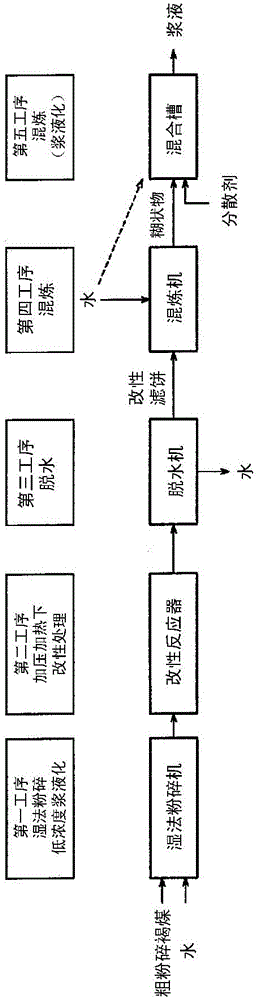

Method used

Image

Examples

Embodiment

[0060] (first process)

[0061] Lignite (Lignite from Australia (Loy Yang lignite)) having the properties shown in Table 1 is roughly pulverized using a hammer crusher so that particles with a particle size of 3 mm or less account for 90% by weight or more (particles passing through a sieve with a mesh size of 3 mm) It is more than 90% by weight of the whole lignite). The roughly pulverized lignite was put into an indirect heating dryer (a small steam tube dryer manufactured by Kawasaki Heavy Industries) and dried at 0.1 MPa and 180° C. for one hour to obtain dried lignite with a total moisture content of 10% by weight. The water vapor discharged from the indirect heating type dryer is cooled by a water-cooled condenser and recovered as condensed water.

[0062] [Table 1]

[0063] .

[0064] (second process)

[0065] Condensed water and a polystyrene-based dispersant were added to 3 kg of dry lignite, and then put into a wet ball mill (φ300 mm×L300 mm, volume: about 21 L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com