Encapsulating method for LED chips

A LED chip and chip packaging technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of large volume, poor heat dissipation effect of LED chips, and poor firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

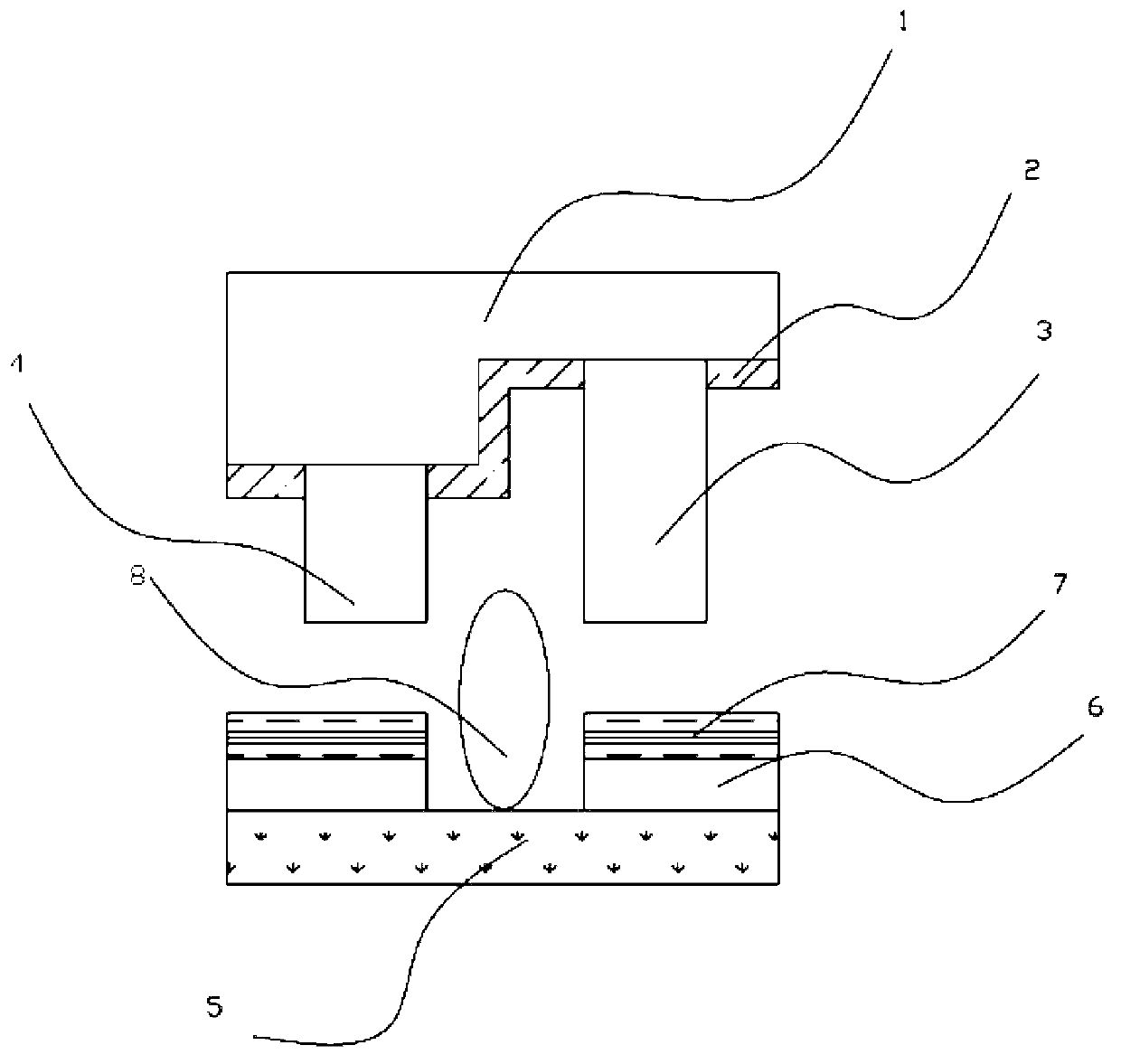

[0014] Such as figure 1 A LED chip packaging method is shown. The LED chip includes a substrate 1 , an insulating layer 2 , a P pole 3 and an N pole 4 . The insulating layer 2 , the P pole 3 and the N pole 4 are all arranged on one side of the substrate 1 , and the insulating layer 2 is laid on the substrate 1 except the P pole 3 and the N pole 4 . The material of the insulating layer 2 can be silicon dioxide. The thickness of the insulating layer 2 is between 4000 angstroms and 10000 angstroms. In this way, when the LED chip is heated and pressurized, the insulating layer 2 is not easily broken, and the insulating effect is better. Make short circuit between P pole 3 and N pole 4 difficult.

[0015] Tin 7 is added to the surface of the electrode 6 of the circuit board substrate 5 .

[0016] Glue 8 is provided on the upper surface of the circuit board substrate 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com