Nanometer semi-conductive non-woven fabric and processing technology thereof

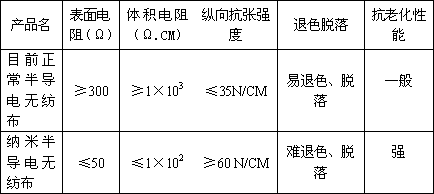

A processing technology and non-woven fabric technology, applied in the field of nano-semiconductive non-woven fabrics and its processing technology, can solve the problems of low tensile strength, easy to fall off, large surface resistance, large volume resistance, etc., to achieve high tensile strength, Small volume resistance, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

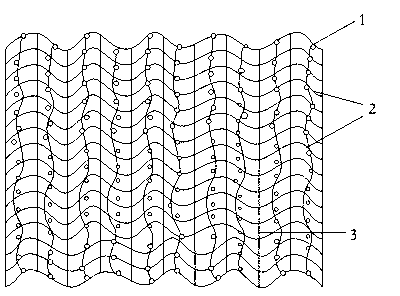

[0023] The invention comprises a fiber net formed by interweaving conductive carbon fiber short fibers 2; the fiber net is longitudinally and parallelly arranged with reinforcing carbon fiber polyester yarns 3; the surface of the fiber net is coated with conductive liquid.

[0024] The fiber web: the grammage is 10g / ㎡.

[0025] The reinforced carbon fiber polyester yarn 3: the thickness is 30dtex, and the distance between the yarns is between 2mm.

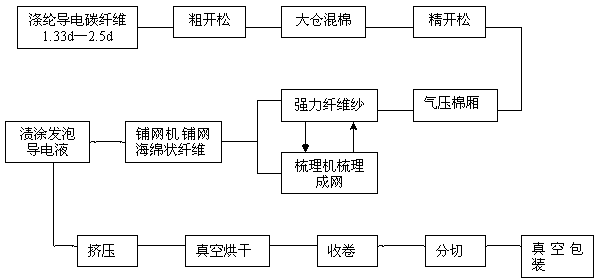

[0026] Nano-semiconductive non-woven fabric processing technology, according to the following process steps:

[0027] 1) Using new conductive carbon fiber staple fiber 2 new materials: After non-woven fabric carding process: fiber staple fiber 2 rough opening → big warehouse blending → fine opening → air pressure cotton box → carding machine → web laminating machine, forming A layer of fiber sponge with a uniform thickness, the weight is 10g / ㎡;

[0028] 2) Longitudinal linear laying process of high-strength yarn: the reinforced c...

Embodiment 2

[0038] The invention comprises a fiber net formed by interweaving conductive carbon fiber short fibers 2; the fiber net is longitudinally and parallelly arranged with reinforcing carbon fiber polyester yarns 3; the surface of the fiber net is coated with conductive liquid.

[0039] The fiber web: the grammage is 70g / ㎡.

[0040] The reinforced carbon fiber polyester yarn 3: the thickness is 50dtex, and the distance between the yarns is between 5mm.

[0041] Nano-semiconductive non-woven fabric processing technology, according to the following process steps:

[0042] 1) Using new conductive carbon fiber staple fiber 2 new materials: After non-woven fabric carding process: fiber staple fiber 2 rough opening → big warehouse blending → fine opening → air pressure cotton box → carding machine → web laminating machine, forming A layer of fiber sponge with a uniform thickness, the weight is 70g / ㎡;

[0043] 2) Longitudinal linear laying process of high-strength yarn: the reinforced c...

Embodiment 3

[0053] The invention comprises a fiber net formed by interweaving conductive carbon fiber short fibers 2; the fiber net is longitudinally and parallelly arranged with reinforcing carbon fiber polyester yarns 3; the surface of the fiber net is coated with conductive liquid.

[0054] The fiber web: the grammage is 50g / ㎡.

[0055] The reinforced carbon fiber polyester yarn 3: the thickness is 40dtex, and the distance between the yarns is between 3mm.

[0056] Nano-semiconductive non-woven fabric processing technology, according to the following process steps:

[0057] 1) Using new conductive carbon fiber staple fiber 2 new materials: After non-woven fabric carding process: fiber staple fiber 2 rough opening → big warehouse blending → fine opening → air pressure cotton box → carding machine → web laminating machine, forming A layer of fiber sponge with uniform thickness, the weight is 50g / ㎡;

[0058] 2) Longitudinal linear laying process of high-strength yarn: the reinforced car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com