Lithography illumination system

A lighting system and lithography technology, applied in microlithography exposure equipment, optics, optical components, etc., can solve the problem of low transmittance at the edge of the coated glass lens, affecting the uniformity of light intensity distribution, and uneven mask surface. Sensitivity and other issues, to avoid impact, strong practicability, and enhance the effect of light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

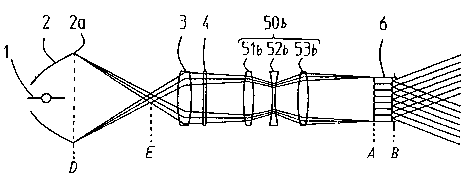

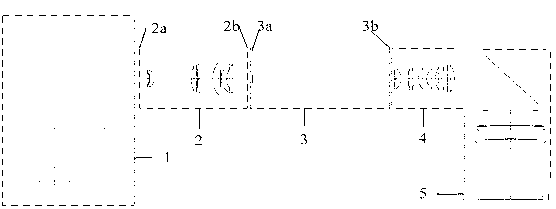

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The specific structure of the lithography lighting system of the present invention is as follows: image 3 As shown, the illumination system includes: a high pressure mercury lamp 1 , a coupling lens group 2 , a quartz rod 3 , a relay lens group 4 and a mask plate 5 . The light emitted by the mercury lamp 1 is converged by the ellipsoid reflector and then incident on the incident end face 2a of the coupling lens group 2, the light beam is emitted from the outgoing end face 2b after being converged by the coupling lens group 2, and irradiates the incident end face 3a of the quartz rod 3, After the light beam undergoes multiple total reflections in the quartz rod 3, uniform illumination light is formed on the exit end face 3b of the quartz rod. The image is formed on the mask plate 5 , and a required illumination field of view with a certain nume...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap