Method and device for rapidly extracting saturation pore water from cement-based material

A cement-based material, pore water technology, applied in sampling devices and other directions, can solve the problems of unsuitable molding and testing of concrete specimens, poor solution filtration function, and reduced filtration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] This will be further explained below in conjunction with the drawings.

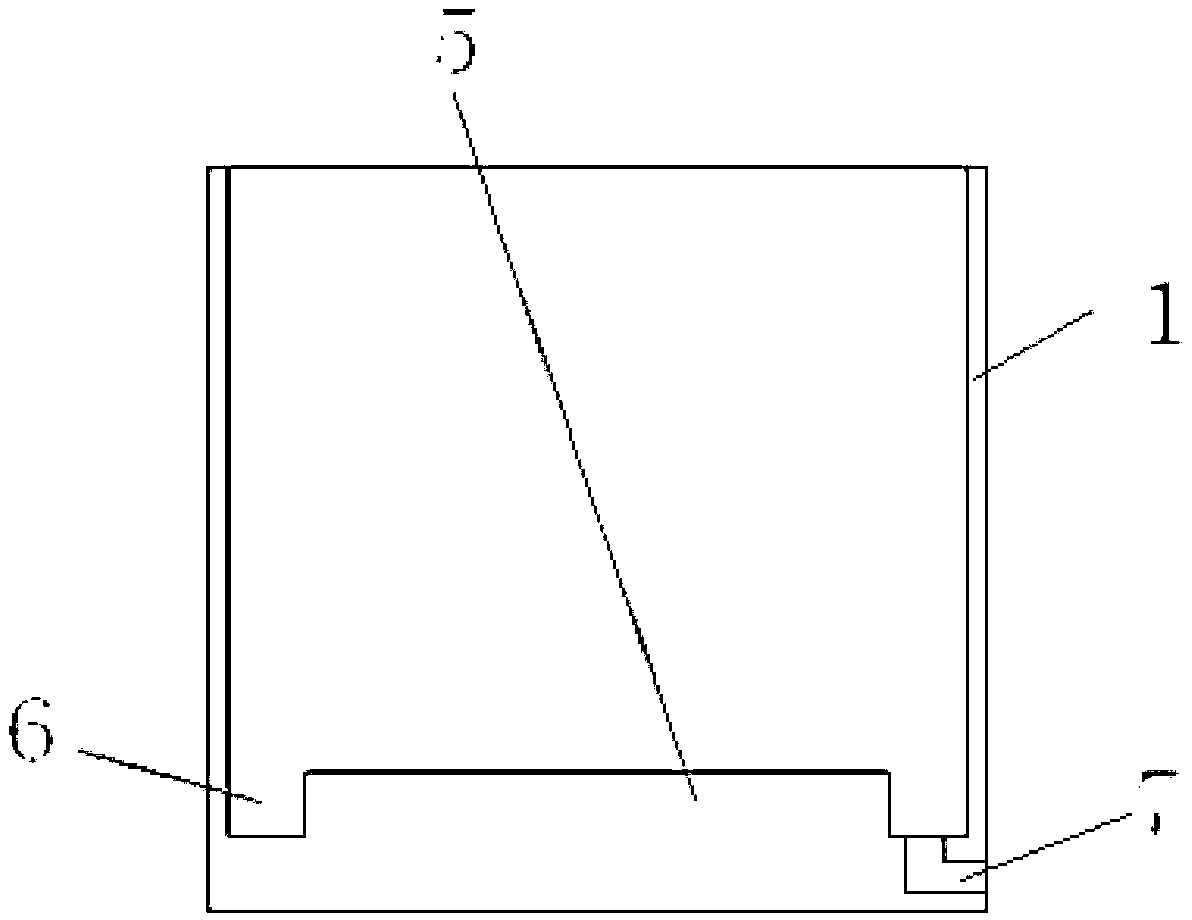

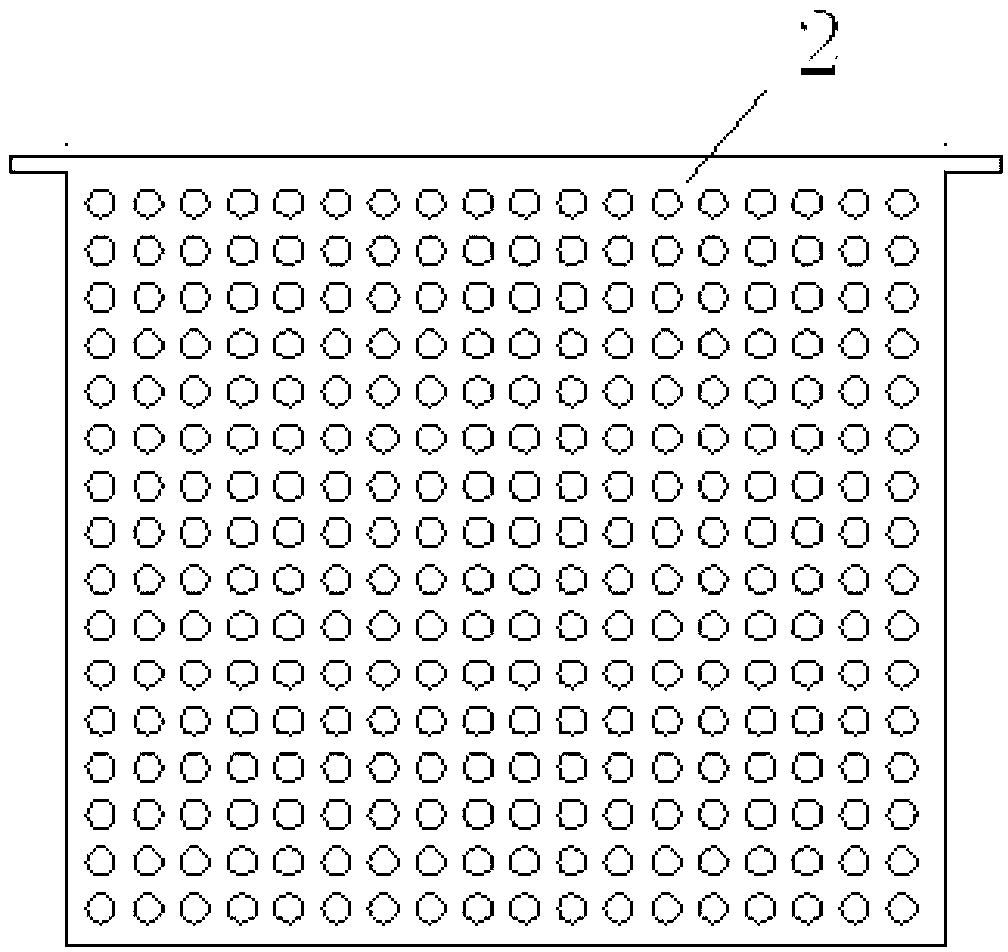

[0037] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , The structure of the hole solution extractor is: the outer cylinder 1 is a hollow cylinder, the upper end has no cover, the bottom is provided with a force surface 5 and a drainage groove 6, the drainage groove 6 is opened with a water outlet 7, and the position of the water outlet 7 is not higher than the drainage Slot 6, the small hole filter screen 2 is a hollow cylinder with no cover at the upper end, positioning plates at both ends, and Φ3~Φ5 holes at the bottom. The small hole filter screen 2 is placed in the outer cylinder 1 and on the stress surface 5. A large-hole inner cylinder 3 is placed in the perforated filter screen 2. The large-hole inner cylinder 3 is provided with outlet holes 8 at least at the bottom and is located on the stress surface 5. The diameter of the outlet holes 8 on the large-hole inner cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com