Gas turbine combustor

A gas turbine and burner technology, which is applied to gas turbine devices, burners, combustion chambers, etc., can solve problems such as poor atomization characteristics, and achieve the effects of promoting atomization and reducing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

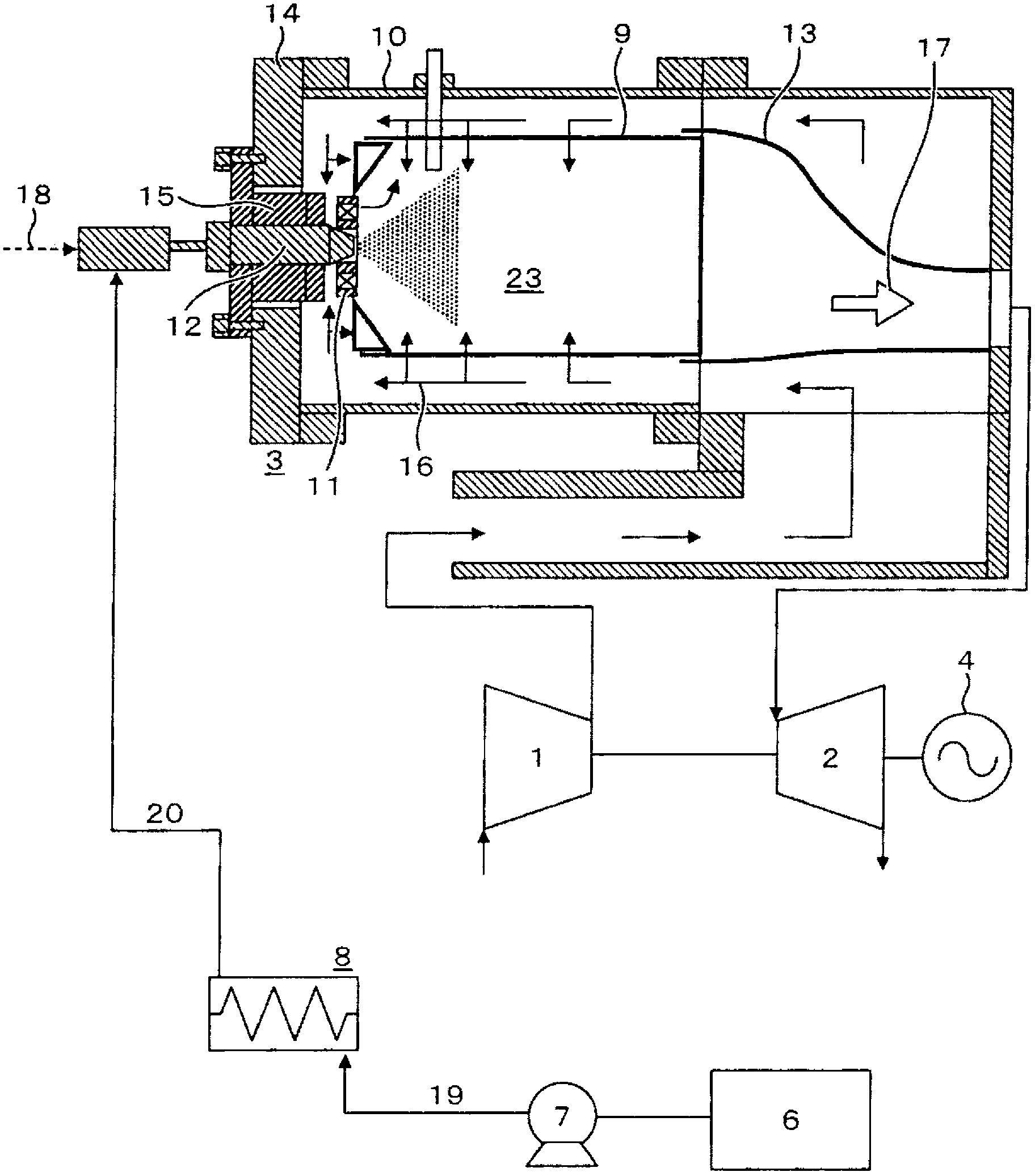

[0027] Refer to the following figure 1 , figure 2 , the first embodiment of the present invention will be described. figure 1 It is a schematic configuration diagram showing the configuration of the first embodiment of the gas turbine combustor according to the present invention in a longitudinal sectional view and schematically showing the overall configuration of a gas turbine device including the gas turbine combustor.

[0028] figure 1 The gas turbine device shown mainly includes: a compressor 1 that compresses air to generate high-pressure combustion air; a combustor 3 that mixes combustion air 16 introduced from the compressor 1 and liquid fossil fuel 18 to generate combustion gas 17; And the turbine 2 that introduces the combustion gas 17 generated by the combustor 3 . In addition, the compressor 1 is connected to the shafts of the turbine 2 and the generator 4 .

[0029] The above-mentioned combustor 3 is composed of the following parts: an inner cylinder 9 formin...

no. 2 approach )

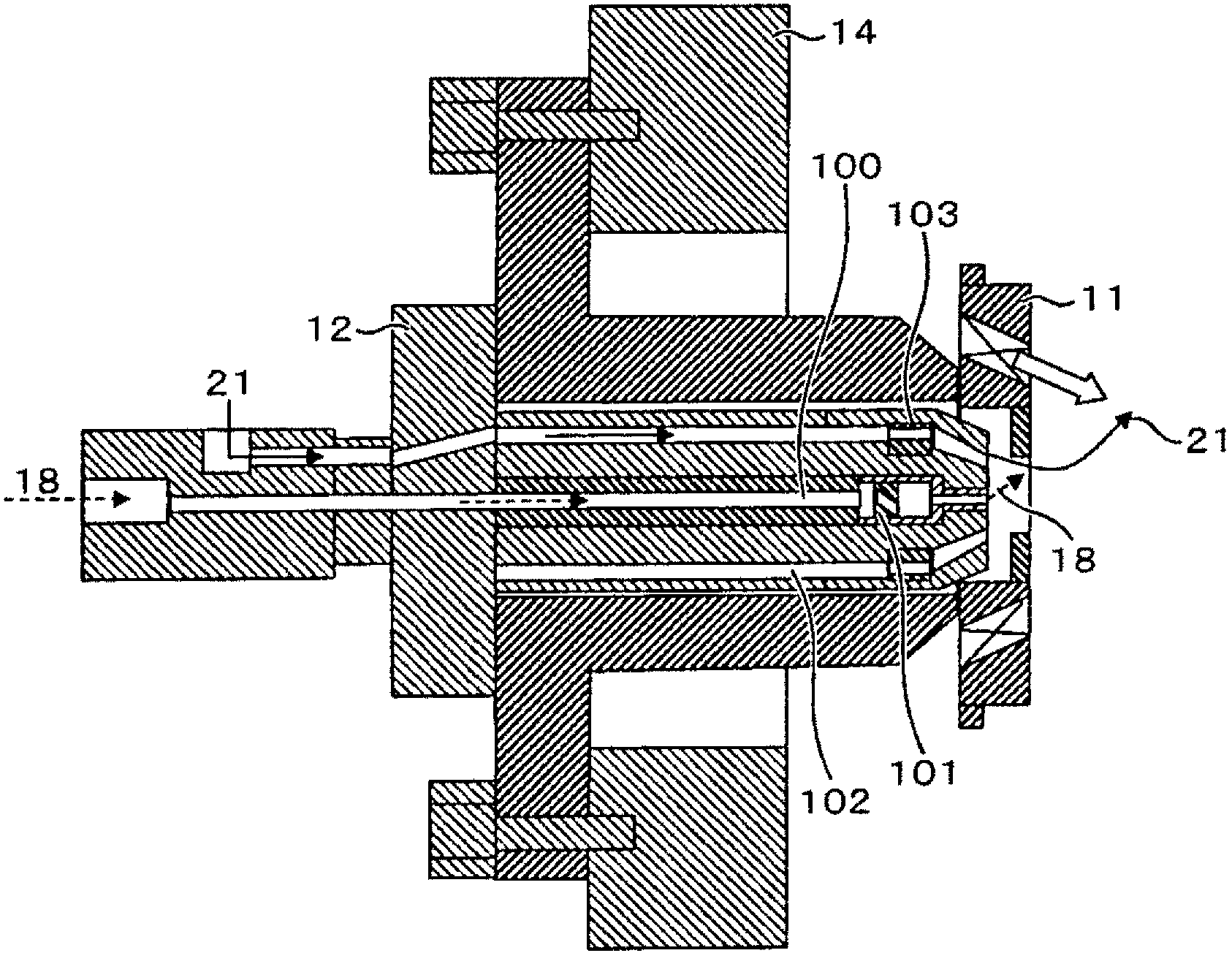

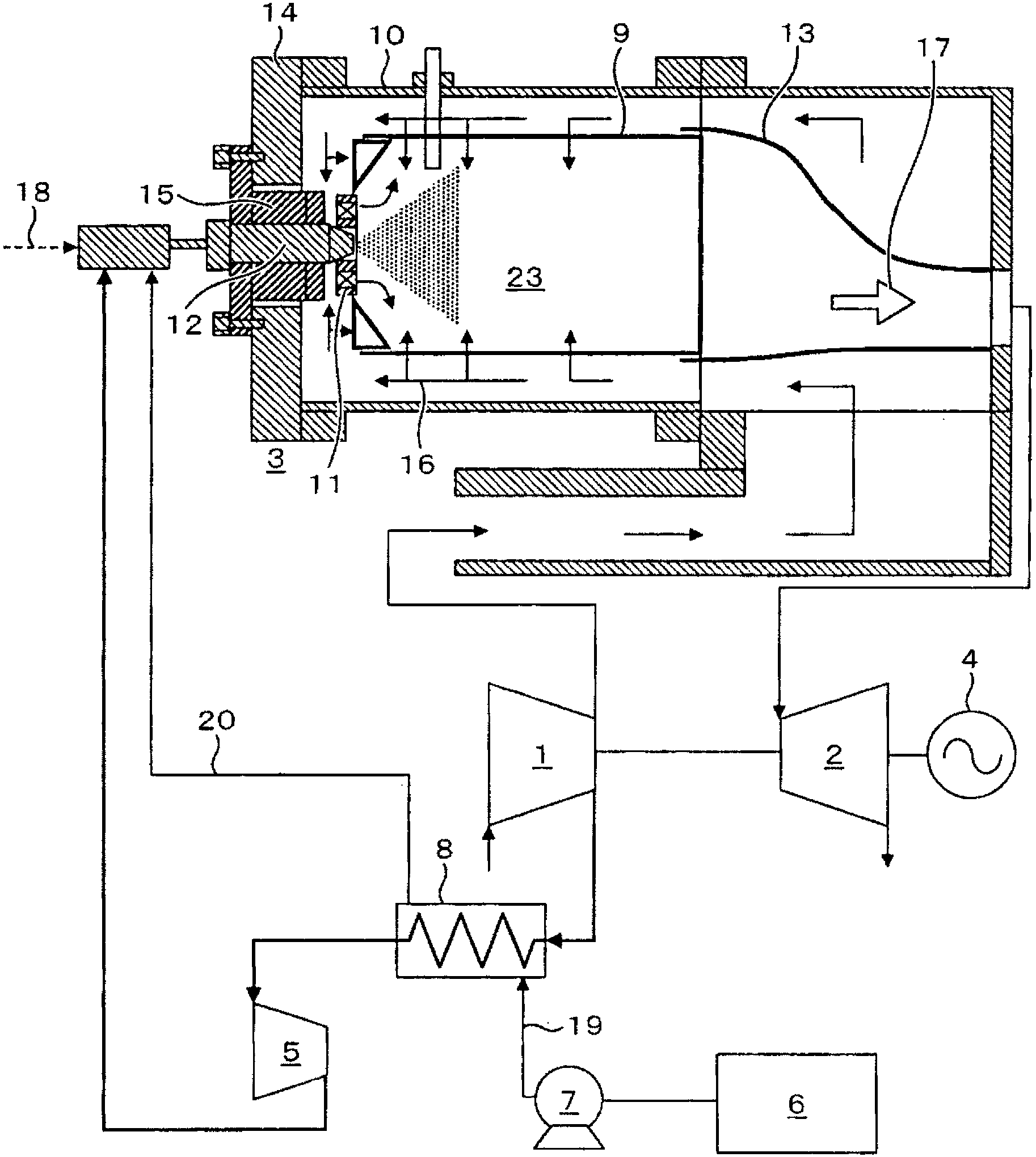

[0041] Refer to the following image 3 , Figure 4 , the second embodiment of the present invention will be described. image 3 It is a schematic configuration diagram showing the configuration of the second embodiment of the gas turbine combustor according to the present invention in a longitudinal sectional view and schematically showing the overall configuration of a gas turbine device including the gas turbine combustor. Figure 4 yes image 3 Partial detailed cross-sectional view of the fuel injection valve 12. The basic structure is the same as that of the first embodiment. This embodiment differs from the first embodiment in that the heat of high-pressure spray air can be used as means for heating a low boiling point liquid fuel (ethanol fuel in this embodiment). and, if Figure 4 As shown, in addition to the liquid fossil fuel system 100 as the first system and the ethanol fuel system 102 as the second system, the fuel injection valve 12 of this embodiment is equi...

no. 3 approach )

[0047] Refer to the following Figure 5 , the third embodiment of the present invention will be described. The basic structure of this embodiment is the same as that of the second embodiment. The present embodiment differs from the second embodiment in that the structure of the injection valve 12 is different. The fuel injection valve 12 of the present embodiment has a discharge hole for injecting liquid fossil fuel 18 formed in the center, a discharge hole for injecting ethanol fuel 21 is formed on its outer periphery, and a discharge hole for injecting spray air 22 is formed on its outer periphery. .

[0048] Generally, the temperature at which a liquid fossil fuel starts to harden by the heat of the surroundings varies depending on the type of fuel. For example, in the case of light oil, the temperature is about 180°C. Therefore, conventionally, from the viewpoint of preventing coking, it was necessary to control the temperature of the high-pressure spray air supplied to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com