Semiconductor light source radiator and light source engine

A light source radiator and semiconductor technology, applied in the direction of light source, point light source, lighting and heating equipment, etc., can solve the problems of low cost of structural materials, poor heat dissipation performance of lamps and lanterns, and insufficient openings, so as to reduce material cost and material cost The effect of reduction and high manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

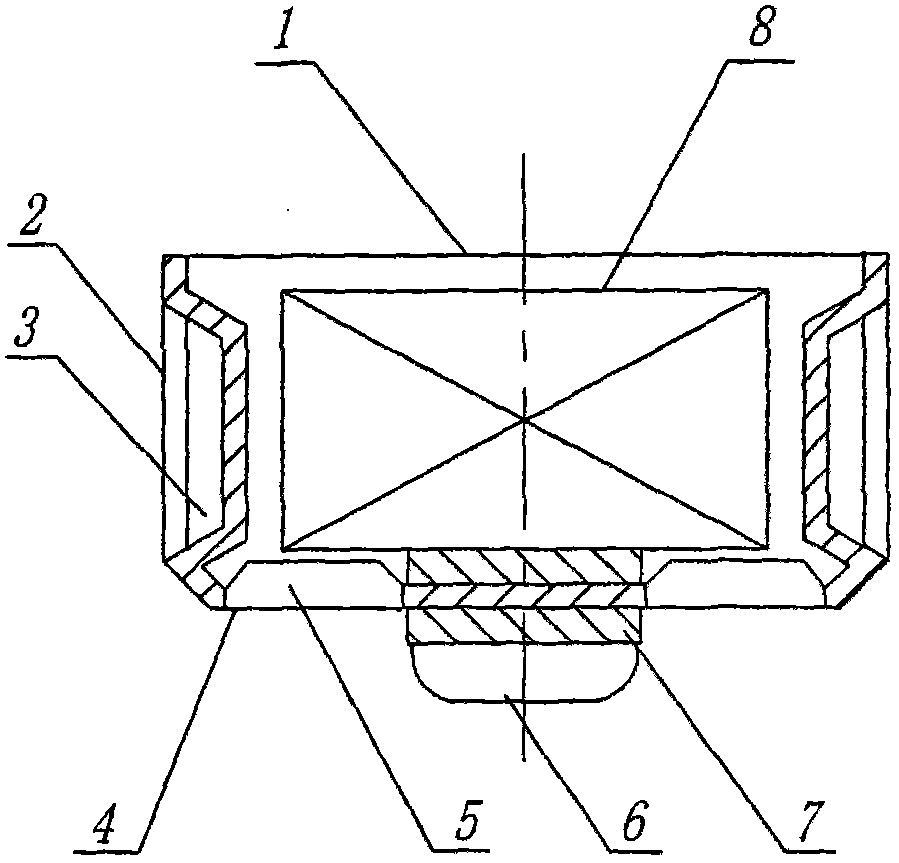

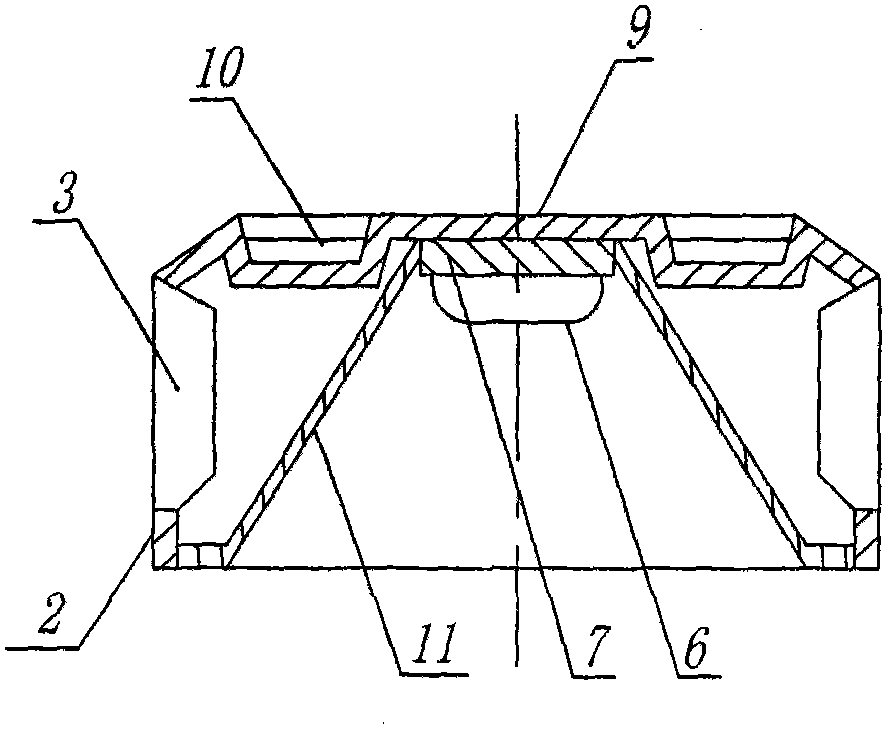

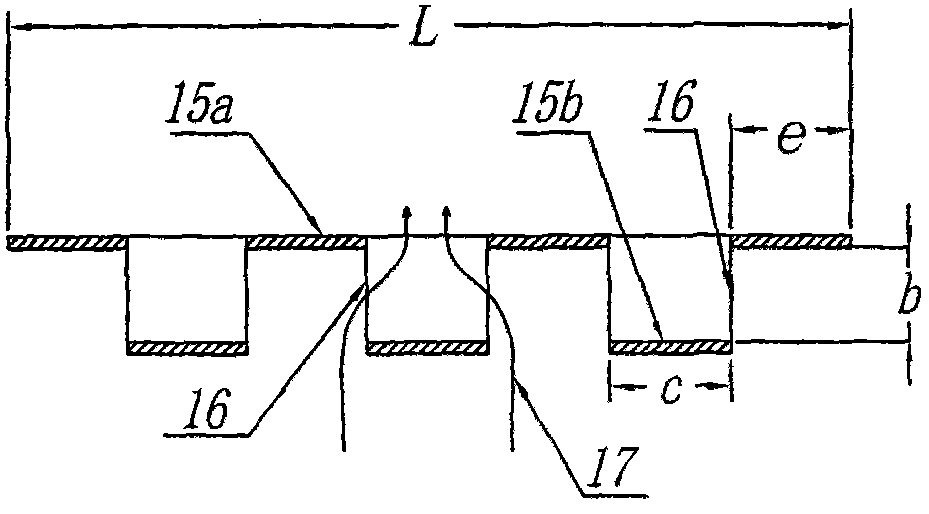

[0028] figure 1 In the shown semiconductor light source engine of the present invention, the metal side wall 2 of the heat dissipation metal shell 1 is an integral structure with the metal front shell 4, that is, it is made of the same metal plate, and the heat dissipation metal shell 1 is provided with a heat sink 8, and there is no metal in the figure. The rear shell and the metal side wall 2 are provided with a staggered ventilation window 3, the ventilation window 5 on the metal front shell 4 adopts a louver-like structure, and the semiconductor light source 6 is arranged on the heat conduction plate 7, which is directly attached to the heat conduction plate In the middle of the metal front shell 4, the contact surface between the middle of the metal front shell 4 and the heat conduction plate 7 is the contact heat transfer surface, here is the direct contact heat transfer surface. The heat generated by the semiconductor light source ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average wall thickness | aaaaa | aaaaa |

| Average wall thickness | aaaaa | aaaaa |

| Average wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com