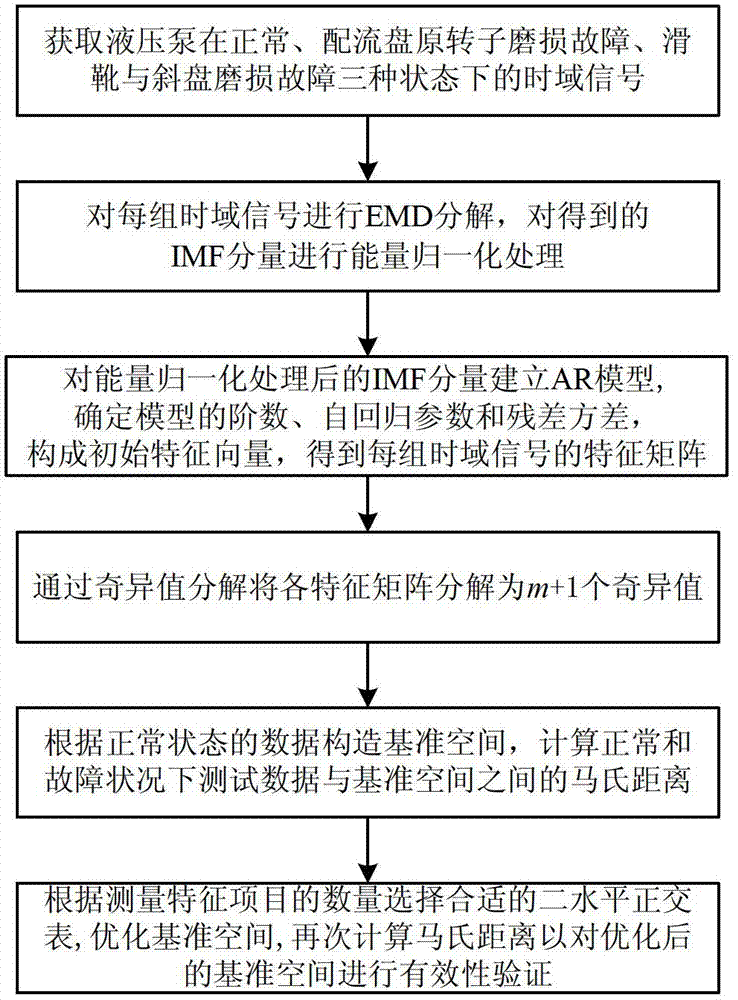

Fault diagnosis method for hydraulic pump based on EMD-AR (empirical mode decomposition-auto-regressive) and MTS (mahalanobis taguchi system)

A fault diagnosis, hydraulic pump technology, applied in pump testing, liquid variable capacity machinery, machines/engines, etc., can solve problems such as high cost, complex reasoning, and unsuitable processing, to reduce professional requirements, reduce costs, increase The effect of engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

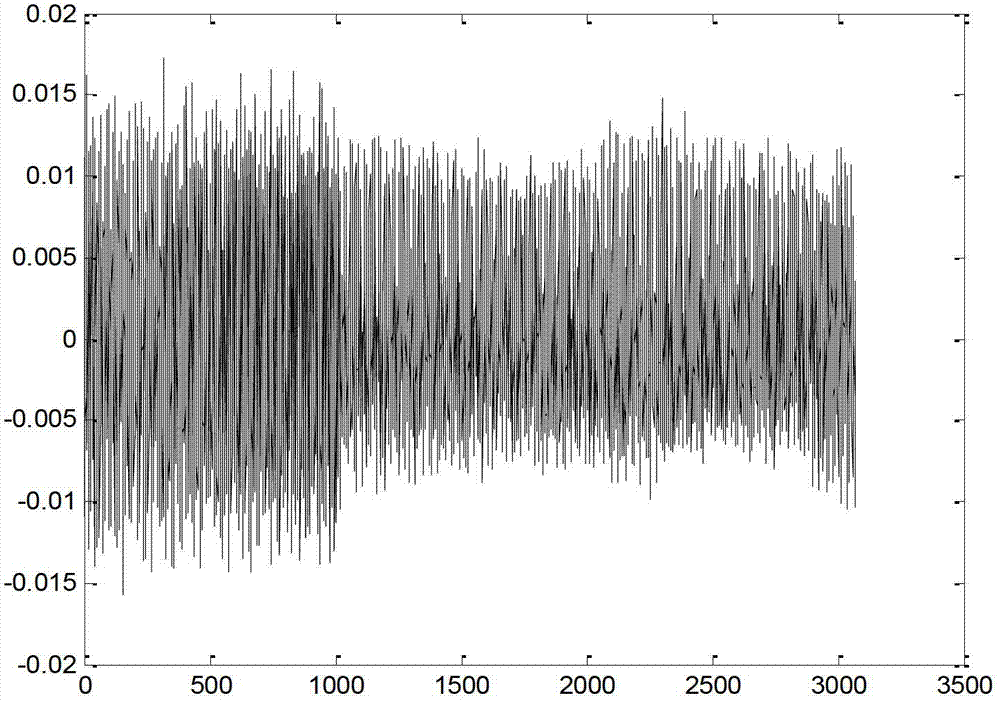

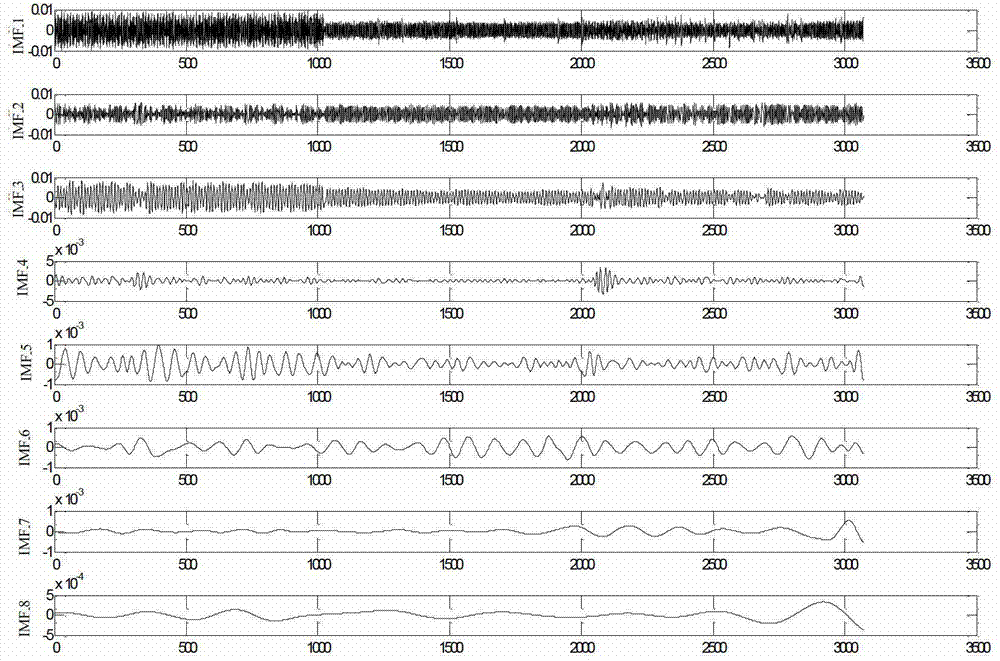

[0080] The experimental research of this example is carried out on the hydraulic pump test bench, using the plunger pump as the experimental object, the pump speed is 5280r / min, and the sampling frequency is 1000HZ. The sample signals collected when the hydraulic pump is normal, the original rotor of the distribution plate is worn, and the sliding shoe and the swash plate are worn are respectively used to detect and verify the hydraulic pump fault diagnosis method based on EMD-AR and MTS of the present invention. The specific steps are as follows:

[0081] Step 1. Under the operating state of the hydraulic pump, collect the time-domain signals under the normal state of the hydraulic pump, the wear fault of the original rotor of the valve plate, and the wear fault of the sliding shoe and the swash plate with the set sampling frequency and sampling time.

[0082] The speed of the hydraulic pump is controlled at 5280r / min, and the signals are collected when the hydraulic pump is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com