Device and method for protecting electromagnetic fan clutch

A protection device, electromagnetic fan technology, applied in the direction of machine/engine, coolant flow control, engine components, etc., can solve the problems of increased exhaust harmful gas emissions, low reliability, increased mechanical wear, etc., to achieve exhaust emissions and reliability. Low resistance, overcoming easy blockage of gaps, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

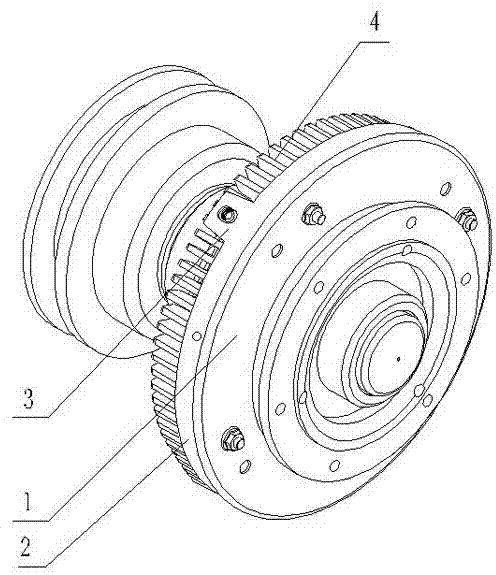

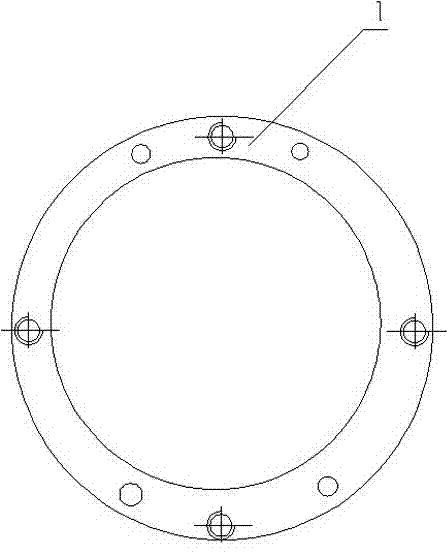

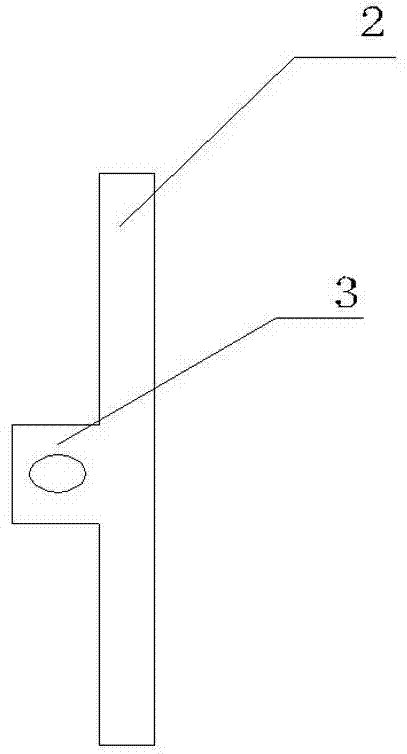

Image

Examples

Embodiment 1

[0040] The above-mentioned electromagnetic fan clutch protection device is applied to the bus, and the test shows that the effect is very good. After two years of use, there is no clogging of the clutch magnetic circuit gap, and the protection separation of metal fragments, metal particles, debris, and metal garbage is more than 95%. The clutch can work stably for a long time, and the energy-saving efficiency is obvious. It completely solves the clutch failure, blockage of the magnetic circuit gap, engine boiling and other accidents caused by the clutch often absorbing metal fragments and metal particles due to the magnetic circuit gap. The thermal efficiency of the engine is also significantly improved, and the service life is extended. To five times, the winter heating effect of the matching heating system is significantly improved.

[0041] The locking metal particle debris protection plate installed on the electromagnetic fan clutch is used to isolate the gap between the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com