Gate-type double-tower gear-driven drilling machine

A door-type and drilling rig technology, applied in the direction of rotary drilling rigs, drill pipes, drill pipes, etc., can solve the problems of large power consumption friction resistance, drilling efficiency discount, tripping drill pipe, drilling tool efficiency, etc., to improve operations and mechanical efficiency, reasonable installation and disassembly design, and the effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the practical application form of the present invention is not limited to the following embodiments.

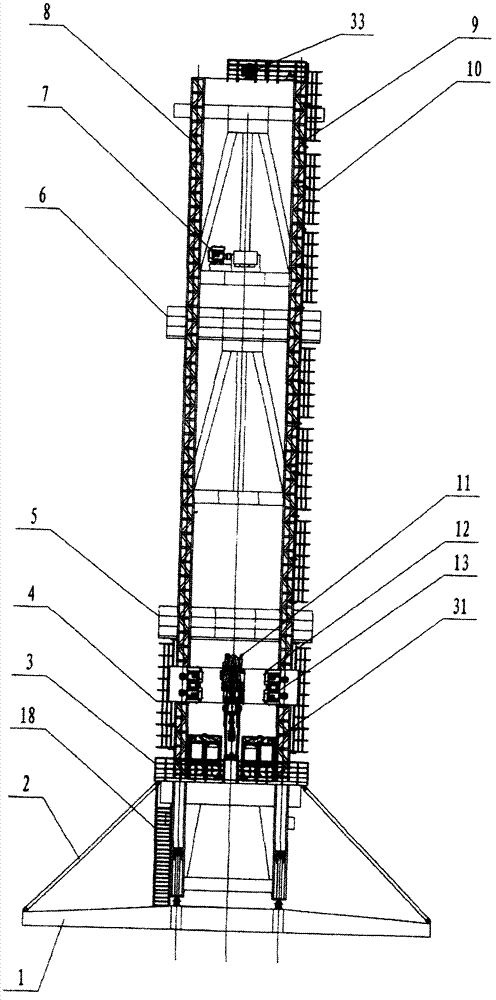

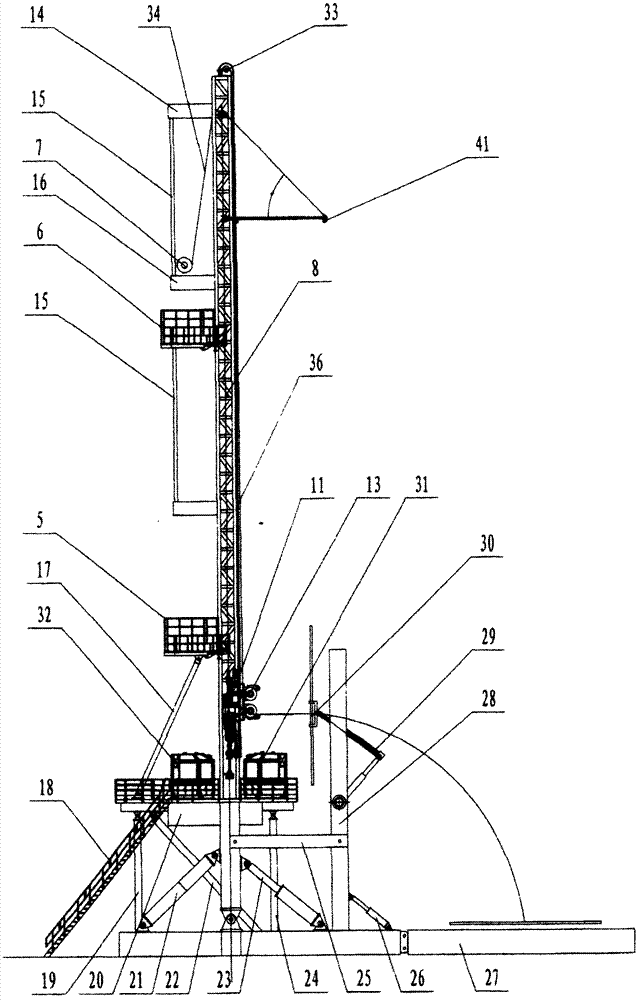

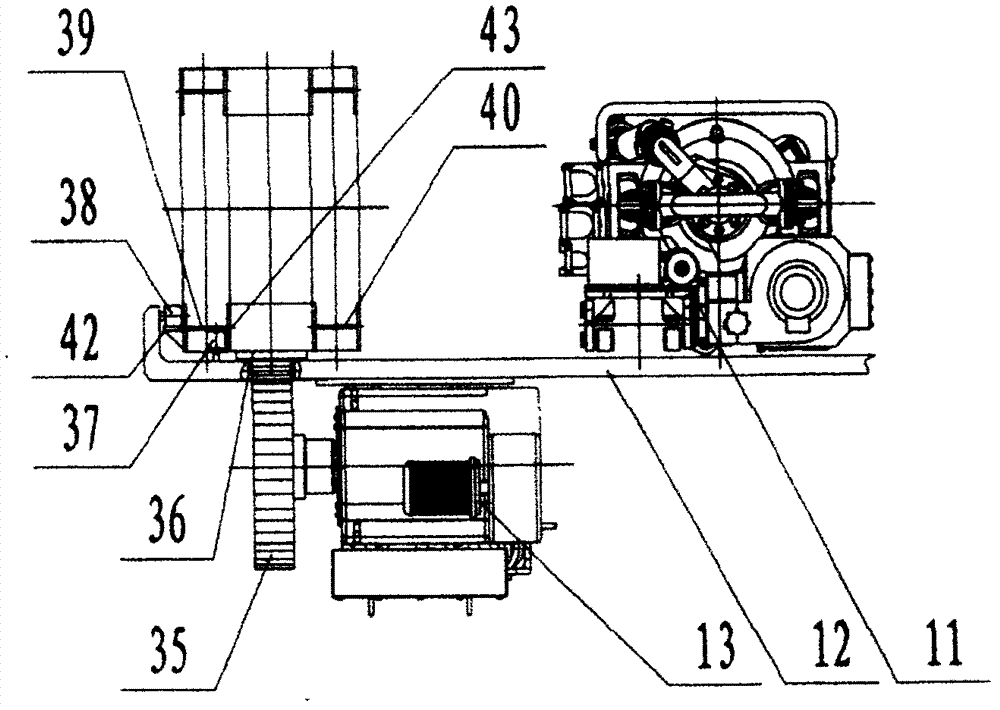

[0034]Referring to the accompanying drawings, the gantry-type double-tooth tooth-driven drilling rig of the present invention includes a derrick, a base, a top drive 11, a top drive block 12, a single drill pipe two-story platform 5, and a double (stand) drill pipe two-story platform 6 , quick tripping device, make-up and breakout device, drill pipe 30, drill pipe transfer device 29, chuck, drill pipe transfer control system 31, driller control system 32, derrick and base lifting system and other parts. The base of derrick is made up of bottom 1, strut 2, inclined ladder 18, straight strut 19, upper strata 20, diagonal strut 22, straight strut 24, pipe grab beam 25 and pipe grab support 28 etc. The main body of the derrick is vertically installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com