Double-hole drainage pipe

A drainage pipe and inner pipe technology, applied in the field of double-hole drainage pipes, can solve the problems of cumbersome construction procedures, difficult maintenance, and large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

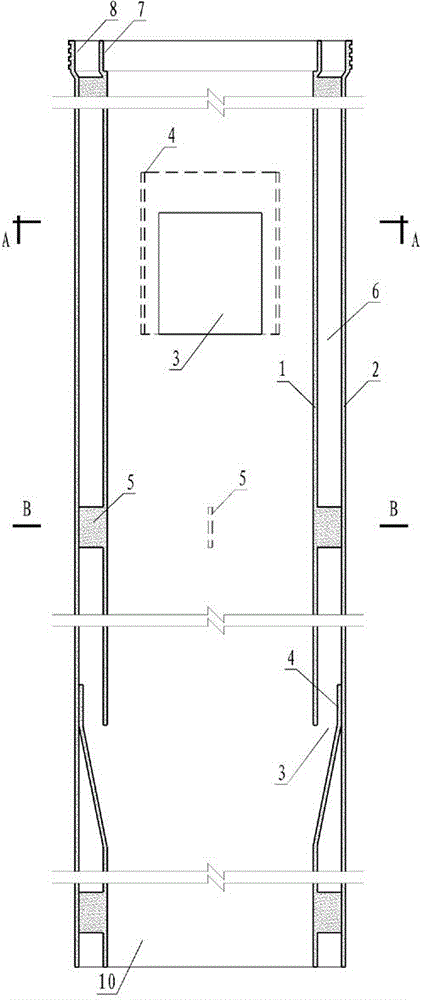

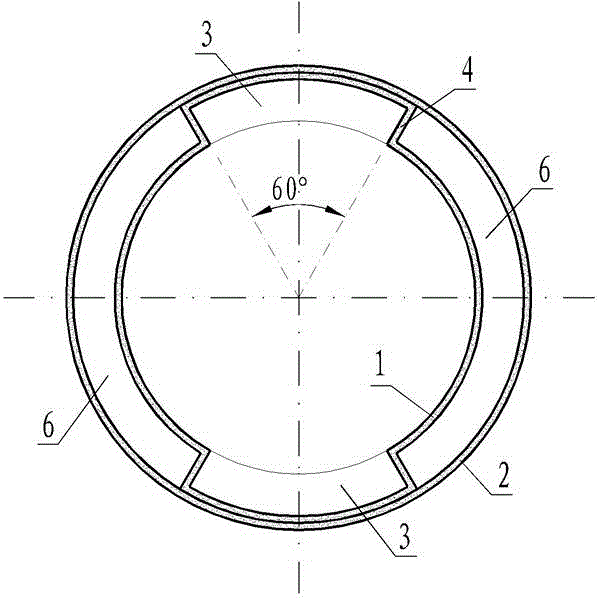

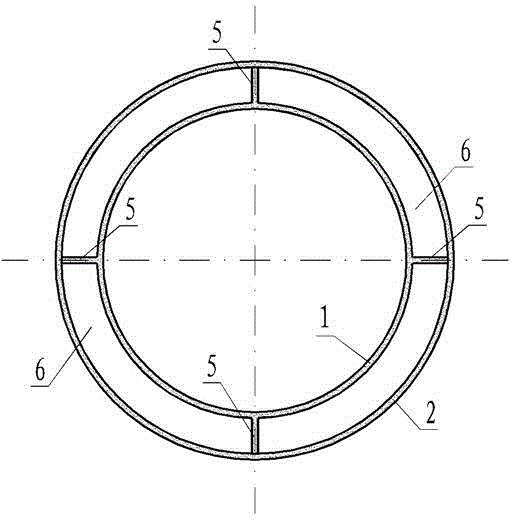

[0028] The double hole drainage pipe of the present invention is made of PVC or UPVC material. The inner pipe 1 of the straight pipe 10 is a circular pipe with an inner pipe socket 7 at one end, and a vent 3 is arranged on the outside every 50 cm. The central angle corresponding to the vent 3 is 60°, and the number of each vent 3 is Two, arranged symmetrically at 180°, and two adjacent air vents 3 are arranged staggered at 90°. The outer side of the vent 3 is provided with side wings 4, which are dustpan-shaped and formed together with the inner tube 1, and the top of the side wings 4 grows 3 to 5 cm beyond the edge of the vent 3 along the ventilation direction. The outer side of the inner tube 1 is provided with positioning tenons 5 at regular intervals (in the middle of the two air vents 3) and at both ends. The four positioning tenons 5 are evenly distributed at 90°, and the positioning tenons 5 are also aligned with the inner tube 1. Shaped together. The outer diameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com