A kind of preparation method of polymerized micro-modified bright polyester fiber

A technology of high glossy polyester and micro-quantity, which is applied in fiber treatment, fiber chemical characteristics, single-component polyester rayon, etc., can solve the problems of poor friction resistance and low fiber strength, and achieve excellent mechanical properties, Low hardness, whiteness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

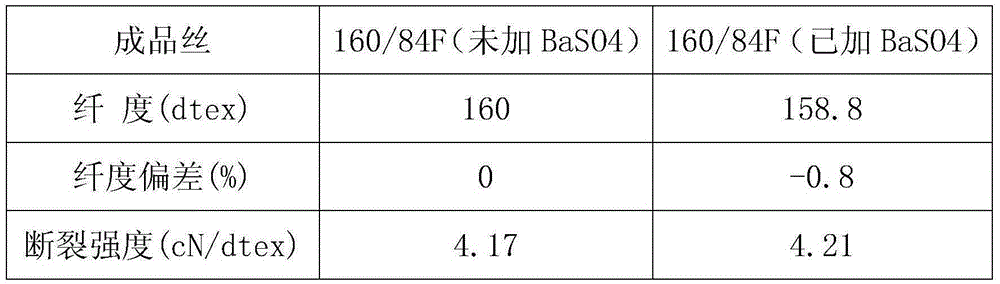

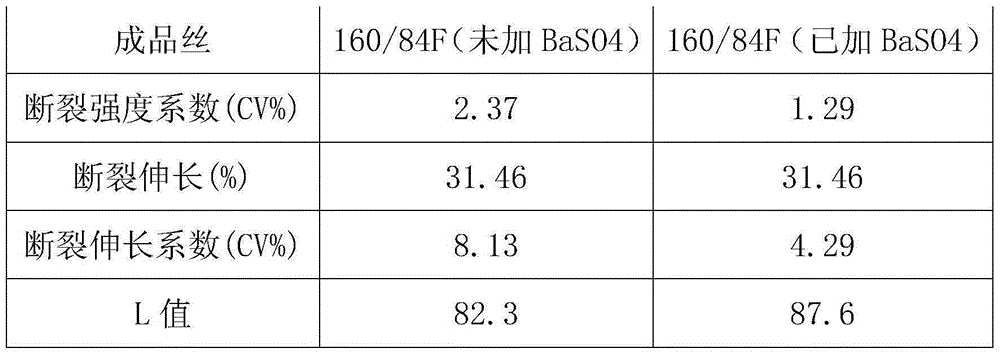

[0019] Such as figure 1 Shown, a kind of preparation method of polymerization micro-modified bright polyester fiber, successive steps are as follows:

[0020] The first step, the preparation of nano-barium sulfate micro-modified polyester melt: phthalic acid and ethylene glycol respectively enter the slurry preparation tank 3 through the phthalic acid delivery pipeline 1 and No. 1 ethylene glycol delivery pipeline 2, and The slurry is evenly mixed under the action of the stirring motor 4, and simultaneously nano-barium sulfate and ethylene glycol enter the nano-barium sulfate suspension preparation tank 7 through the nano-barium sulfate delivery pipeline 5 and No. 2 ethylene glycol delivery pipeline 6 respectively; During the conveying process, the nano-barium sulfate suspension is mixed with the slurry, and then enters the slurry feeding tank 8, and the slurry passes through the esterification reactor 9, the metering injection pump 10, the catalyst feeding device 11, the prec...

Embodiment 2

[0028] Such as figure 1 Shown, a kind of preparation method of polymerization micro-modified bright polyester fiber, successive steps are as follows:

[0029] The first step, the preparation of nano-barium sulfate micro-modified polyester melt: the nano-barium sulfate and ethylene glycol are respectively passed through the nano-barium sulfate delivery pipeline 5 and the second ethylene glycol delivery pipeline 6 into the nano-barium sulfate suspension preparation tank 7. Prepare a nano-barium sulfate suspension; phthalic acid and ethylene glycol enter the slurry preparation tank 3 through the phthalic acid delivery pipeline 1 and No. 1 ethylene glycol delivery pipeline 2 respectively, and make the slurry under the action of the stirring motor 4 The material is mixed evenly, and then enters the slurry feeding tank 8, and the prepolymer obtained after the slurry passes through the esterification reactor 9 and the metering injection pump 10 is mixed with the nano-barium sulfate s...

Embodiment 3

[0038]The difference from Example 2 is that the particle size of the nano-barium sulfate is 0.55-0.66 μm, and the breaking strength of the finished silk is 5.24 cN / dtex after testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com