High-strength cold-rolled steel plate and manufacturing method thereof

A technology of cold-rolled steel sheet and manufacturing method, applied in the field of cold-rolled steel sheet and its manufacturing, capable of solving problems such as insufficient corrosion resistance and poor surface appearance of cold-rolled steel sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

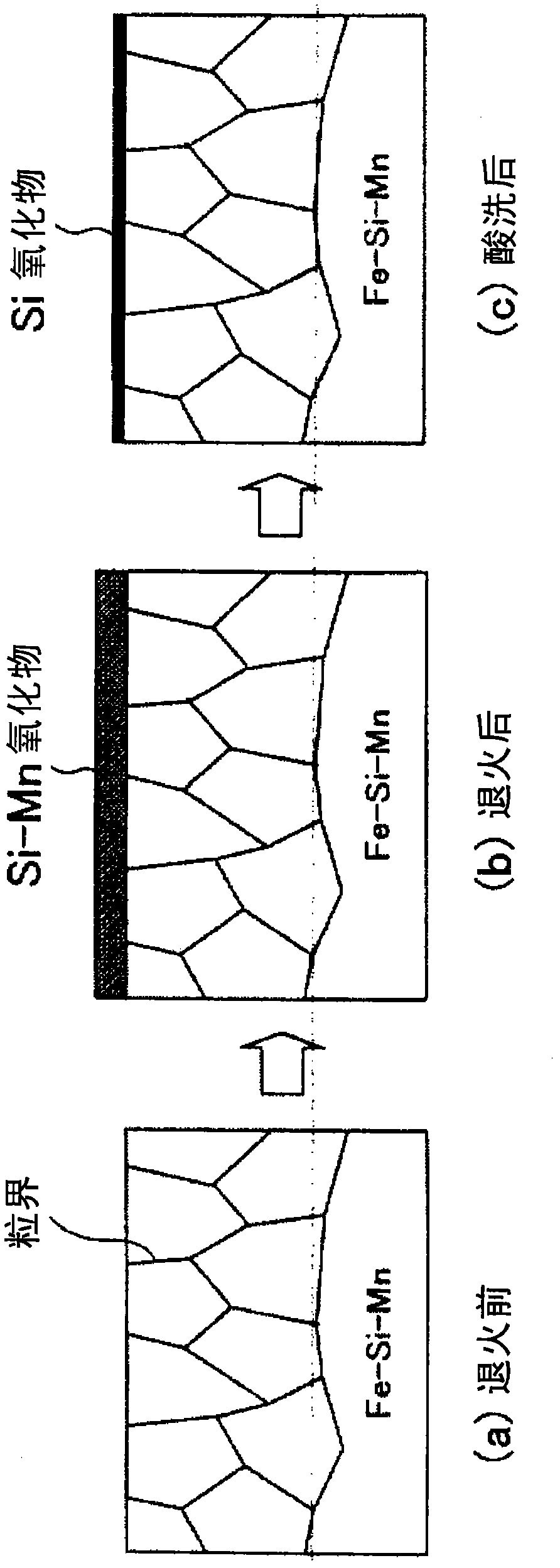

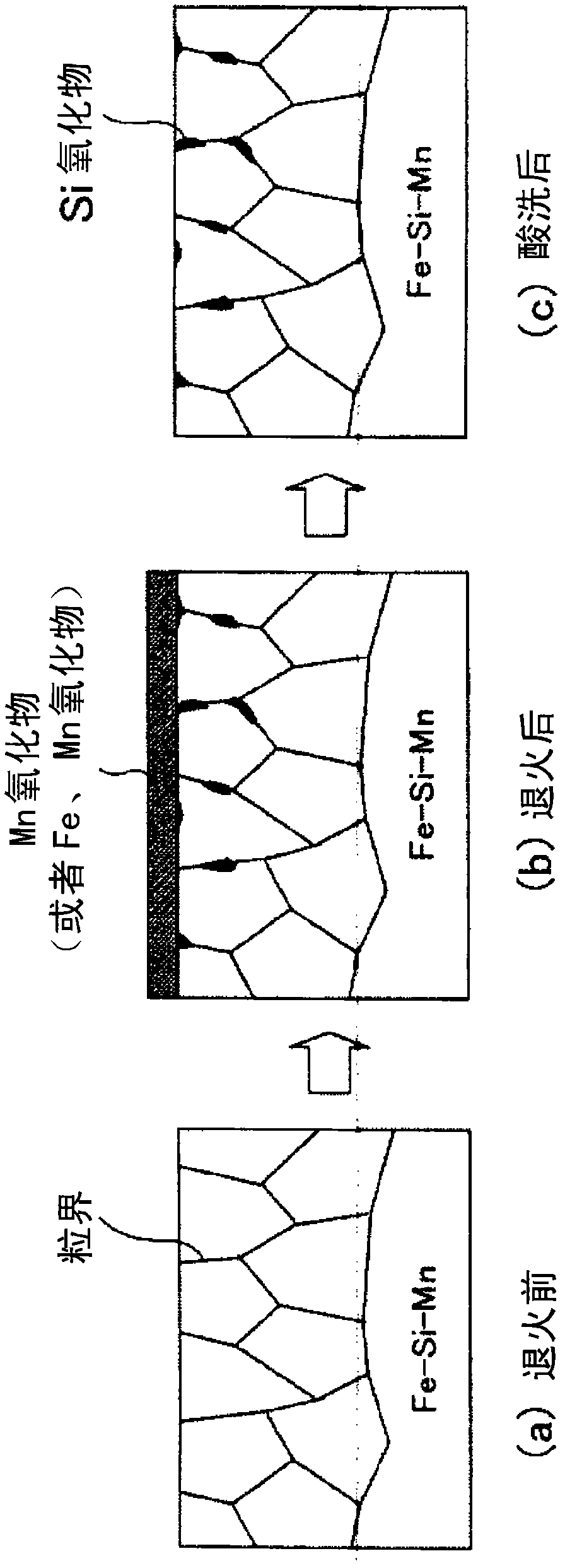

[0161] Using a cold-rolled steel sheet containing 1.2% by mass Si and 2.0% by mass Mn, degreasing, annealing, and pickling were performed under the following conditions to obtain steel sheets with different precipitation forms of Si-containing oxides.

example 1

[0163] Degreasing: immerse in 5% (mass %, hereinafter the same for aqueous solution) sodium hydroxide aqueous solution at 60°C for 30 seconds → wash with water → dry

[0164] Annealing: 3% hydrogen-containing inert gas environment, dew point -20°C, heating at 870°C×200s

[0165] Pickling; immerse in 3% hydrochloric acid aqueous solution at 60°C for 5 seconds → wash with water → dry

[0166] (Example 2 of the present invention)

[0167] Degreasing: Soak in 5% sodium hydroxide aqueous solution at 60°C for 30 seconds → wash with water → dry

[0168] Annealing: 3% hydrogen-containing inert gas environment, dew point -15°C, heating at 870°C×200s

[0169] Pickling; immerse in 3% hydrochloric acid aqueous solution at 60°C for 5 seconds → wash with water → dry

Embodiment 2

[0190] Using a cold-rolled steel sheet containing 1.5% by mass of Si and 1.8% by mass of Mn, it was degreased by immersing it in a 5% sodium hydroxide aqueous solution at 60°C for 30 seconds, washed with water, and dried. After that, as shown in Table 2 , annealed at 840°C for 120 seconds in a 3% hydrogen-containing inert gas environment with different dew points, and then pickled with 3% hydrochloric acid aqueous solution at 60°C for 5 seconds, washed with water, and dried to prepare the test material.

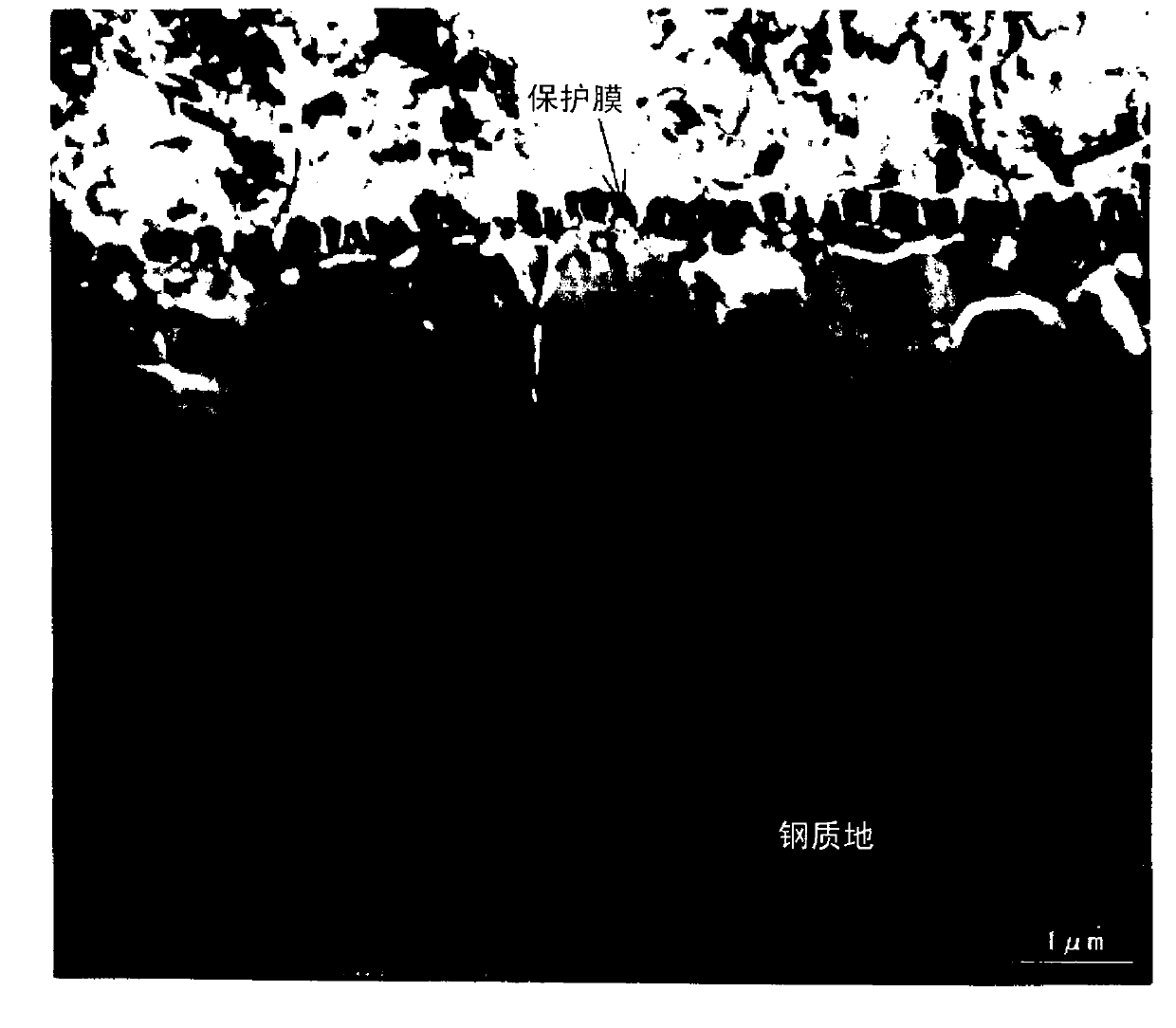

[0191] These test materials were cut in a direction perpendicular to the surface of the steel plate, and the cross-section including the vicinity of the surface was observed by TEM in the same manner as in Example 1 above. That is, for each test material, five samples including samples for TEM observation with a steel plate surface length of 10 μm or more were prepared, observed at a magnification of 60,000, and the amount of Si-containing oxide in the steel plate surface leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com