Automatic environmental protection fermentation system of organic material

An organic material and fermentation system technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and biological organic part treatment, etc., can solve the problems of difficult to achieve clean and environmentally friendly production, insufficient fermentation efficiency and automation, and large site occupation area. Achieve the effect of reducing production turnover links and labor use, reducing production management difficulty and production costs, and good oxygen supply conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

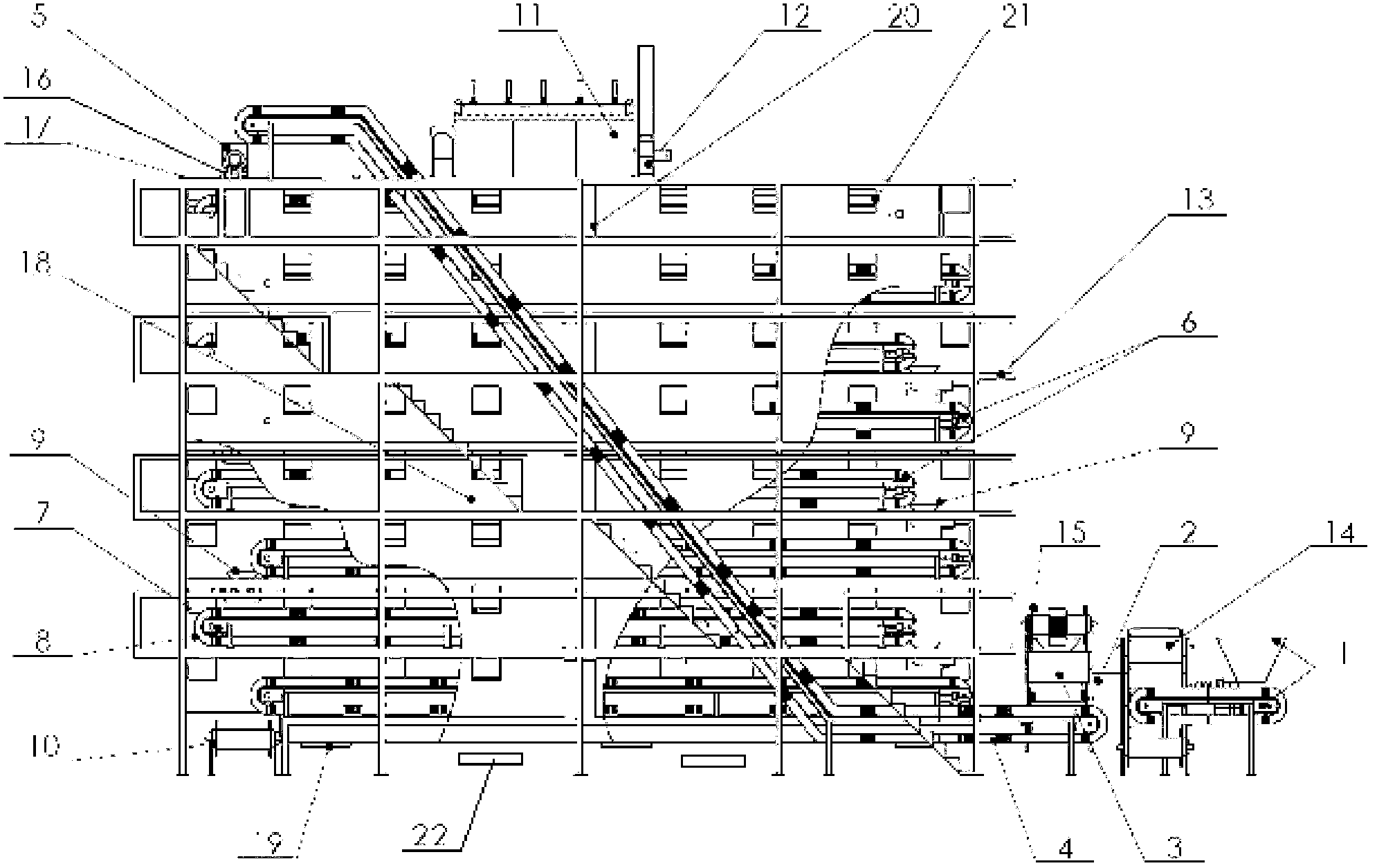

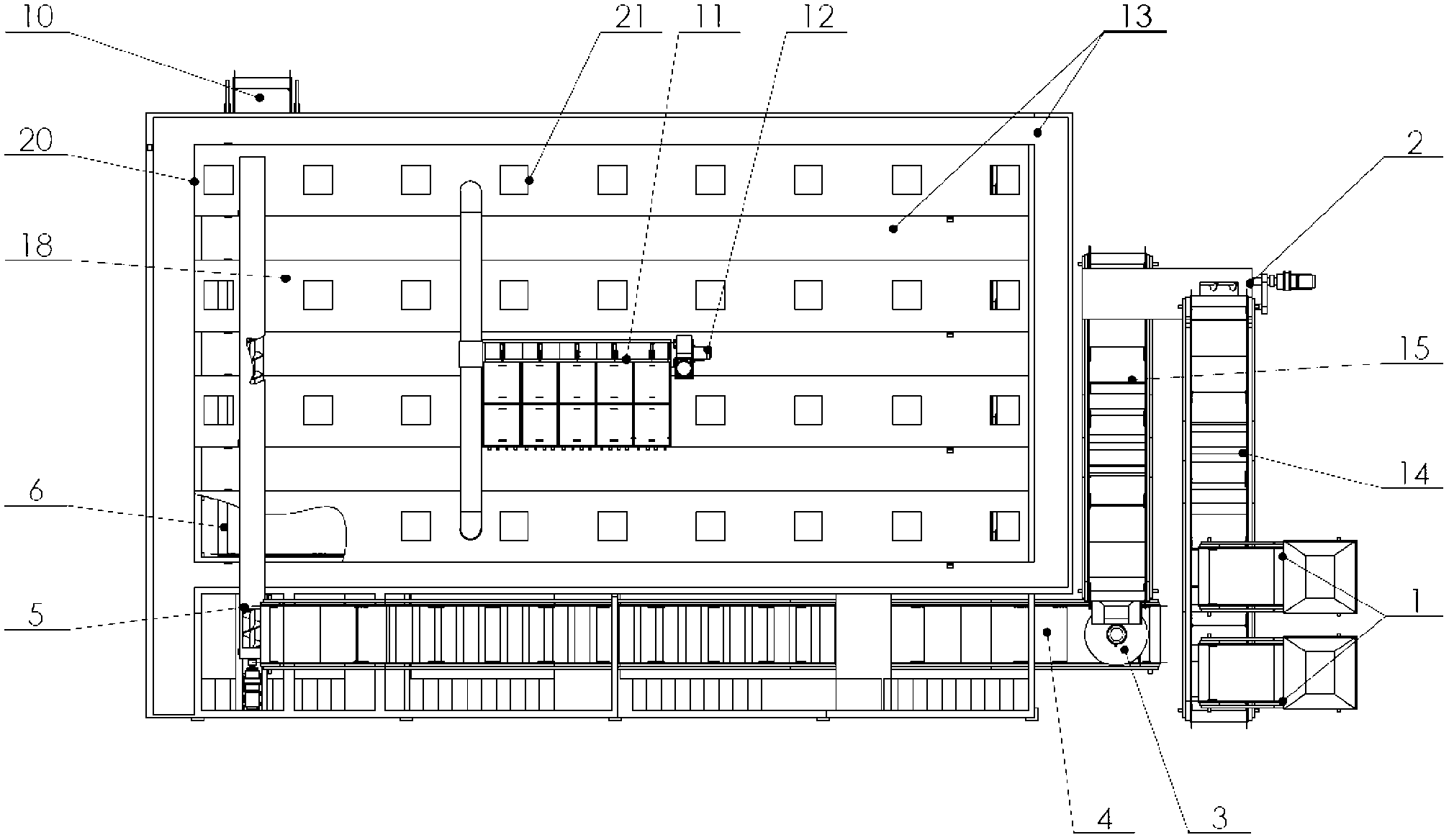

[0035] Such as figure 1, figure 2 As shown, the organic material automatic environmental protection fermentation system of the present invention is mainly composed of a batching device 1, a material stirring device 2, a material crushing device 3, a material hoist 4, a material distribution conveyor 5, a material fermentation conveyor unit 6, and a material fermentation conveyor 7. It is composed of sidewall conveyor belt 8, material crushing and cooling device 9, clinker conveyor 10, exhaust gas purification device 11, forced ventilation device 12, and operation channel 13.

[0036] The batching device 1 is installed on the ground plane, the material mixing device 2 is installed at the rear of the batching device 1, and the batching device 1 is connected with the material mixing device 2 through its total output belt conveyor 14; the batching device 1 adopts a computer-controlled automatic batching device, The material stirring device 2 is a twin-shaft screw mixer. The ma...

Embodiment 2

[0051] The organic material automatic environmental protection fermentation system mainly consists of batching device 1, material stirring device 2, material crushing device 3, material hoist 4, material fermentation conveying unit 6, material fermentation conveyor 7, material crushing and cooling device 9, clinker conveyor 10. Exhaust gas purification device 11, forced ventilation device 12, operation channel 13 and other components.

[0052] The structure of the present embodiment 2 is mostly the same as that of the embodiment 1, the only difference is that: the material fermentation conveying unit 6 is provided with 8 groups, each group is provided with 10 layers of material fermentation conveyors 7, and each layer is provided with two material fermentation conveyors. Conveyor 7: installed three-dimensionally from low to high, and the fermentation conveyors between adjacent layers are staggered on the vertical plane. The material fermentation conveyor 7 of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com