Smelting gas acid-production wastewater treatment system

A waste water treatment system and smelting flue gas technology, applied in the direction of water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of excessive toxicity leaching indicators, lower copper and arsenic removal efficiency, sodium sulfide Problems such as high excess rate, to achieve the effect of reducing construction costs, reducing environmental protection investment, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

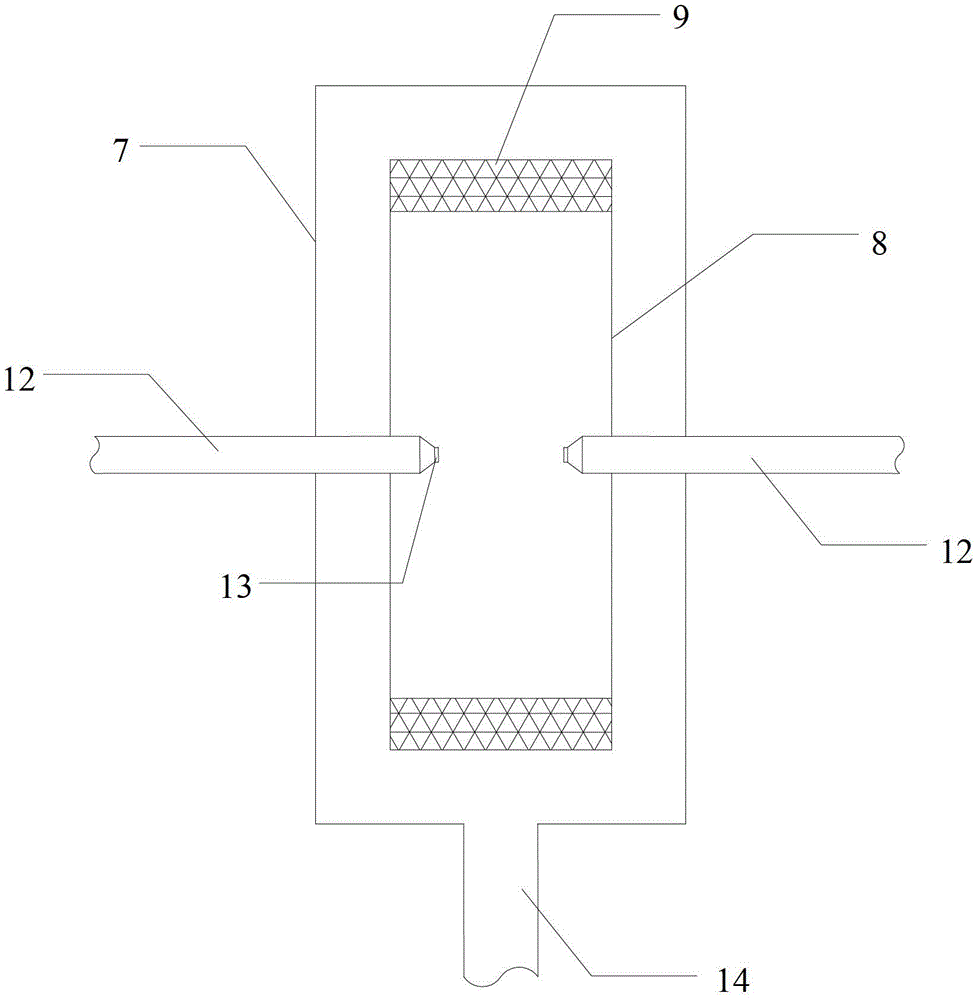

[0020] In order to better understand the purpose, structure and function of the present invention, a smelting flue gas acid production wastewater treatment system of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0021] The following examples are based on the treatment of smelting flue gas acid wastewater discharged from the copper smelting acid system as an example, wherein the wastewater mainly contains copper and arsenic plasma, and the treatment principle is to generate copper and arsenic plasma in the wastewater and sodium sulfide The chemical reaction produces precipitate, which is then removed by thickening and pressure filtration.

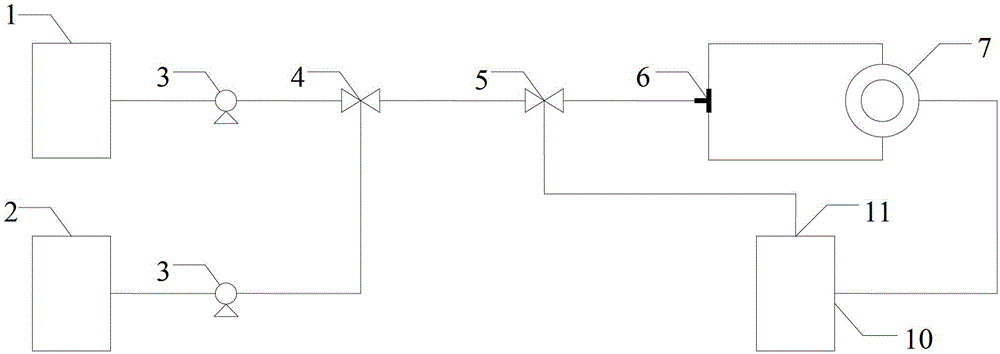

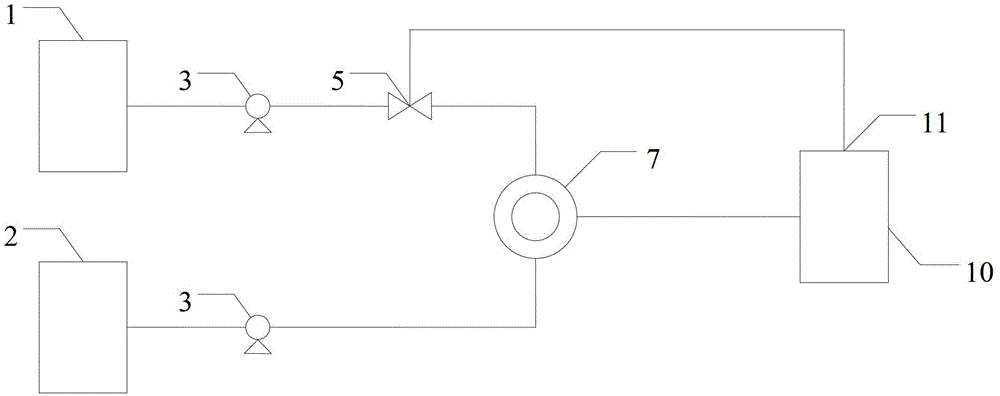

[0022] Such as figure 1 As shown, the smelting flue gas acid production wastewater treatment system of the present invention includes a wastewater storage tank 1 and a chemical storage tank 2, the wastewater storage tank 1 is used to place heavy metal wastewater (such as copper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com