Sealed bottle cap with opening device

A technology for opening devices and bottle caps, which is applied to capping with auxiliary devices, sealing parts with auxiliary devices, and sealing. Easy to disassemble, easy to recycle and reuse, safe and reliable to open

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

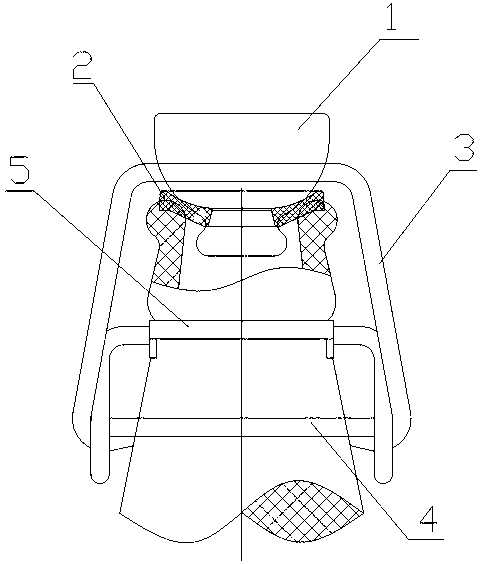

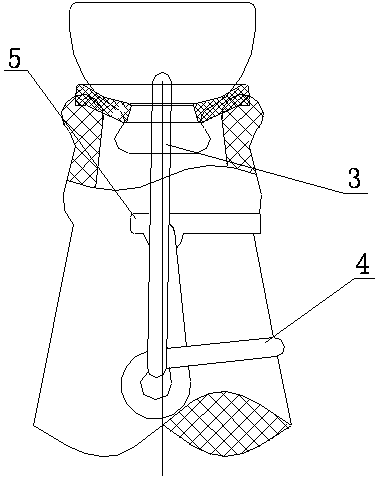

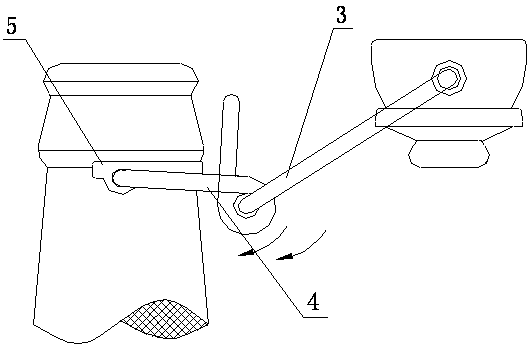

[0029] see Figure 1 to Figure 5 , the invention relates to a sealed bottle cap with an opening device, comprising a bottle cap 1, the bottle cap 1 is a pharmaceutical-grade plastic cap, which has high cleanliness and can ensure the quality of the liquid in the bottle. The side surface of the bottle cap 1 There is a through hole for connecting the first bracket 3, and the lower part of the bottle cap 1 is used for plugging into the bottle mouth. The bottle cap 1 is covered with a sealing ring 2, which is a pharmaceutical grade sealing ring. Low air permeability and moisture permeability, and strong heat resistance, ozone resistance, and aging resistance, which can ensure the sealing of the bottle and will not cause the bottle mouth to break. The shape of the sealing ring 2 matches the bottle mouth, which can ensure the airtightness of the bottle. It is preferably a butyl rubber seal.

[0030] Also be provided with the first bracket 3, the second bracket 4 and the hoop 5 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com