An Adjustable Shear Resistant Structure Used in Large Travel Gear

A walking mechanism and adjustable technology, which is applied in the direction of the running mechanism, transport passenger cars, railway car body parts, etc., can solve the problems of being easily damaged by shear force, installation errors cannot be compensated, and wheels gnaw rails, etc., and the adjustment process is simple and convenient. Improving the effect of wheel gnawing and compensating for installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

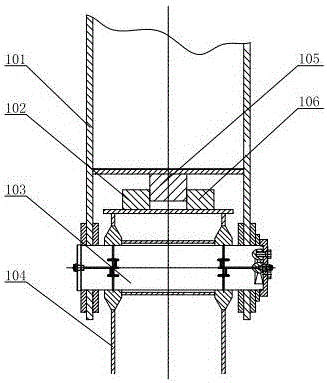

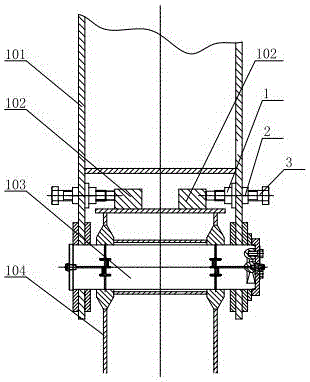

[0015] Such as figure 2 As shown, the present invention includes a balance beam 101. The balance beam 101 is flexibly connected to the trolley frame 104 through a hinge shaft 103, and two first shear blocks 102 are arranged symmetrically at intervals on the trolley frame 104. The diameter of the installation hole is larger than the diameter of the locking bolt 3 and the diameter of the fixing nut 1 by 1 mm to 3 mm. The fixed nut 1 is symmetrically welded on the inner wall of the balance beam 101 , the locking bolt 3 sequentially passes through the installation hole, the fixing nut 1 and abuts against the first shear block 102 , and the locking bolt 3 is fixed by the locking nut 2 . The fixed nut 1, the lock nut 2 and the lock bolt 3 are two sets, and the center point of the fixed nut 1, the lock nut 2 and the lock bolt 3 is the same as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com