Inorganic nano composite catalyst with peroxidase property and application of catalyst for performing catalytic decomposition on TMB thereof

A technology of composite catalyst and peroxidase, which is applied in the field of nanomaterial science and enzyme-like catalysis, can solve the problems of complex extraction process, high price, and inability to recycle and reuse, and achieve the effect of simple process and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] Preparation of graphene oxide (Hummers S, Offeman R, J. Am. Chem. Soc., 1958, 80(6), 1339.): 1?g natural graphite, 1?g NaNO 3 Mix with 46?mL concentrated sulfuric acid (98%) and react in an ice-water bath for 4-5?h. Then 6?g KMnO 4 Add it into the mixture solution while raising the temperature to 35?°C and keep the reaction temperature. After the reaction is carried out for 2~3?h, add 90~95?mL H 2 O and the temperature was raised to 98°C. After two hours of reaction, 200?mL warm water and 20?mL 30% H 2 o 2 , and continue to react at room temperature for 1 ~ 2 h. Keep stirring throughout the reaction. The prepared product was filtered, washed with distilled water, and dried in an oven at 60° C. for 24˜48° h to obtain a yellow graphene oxide solid.

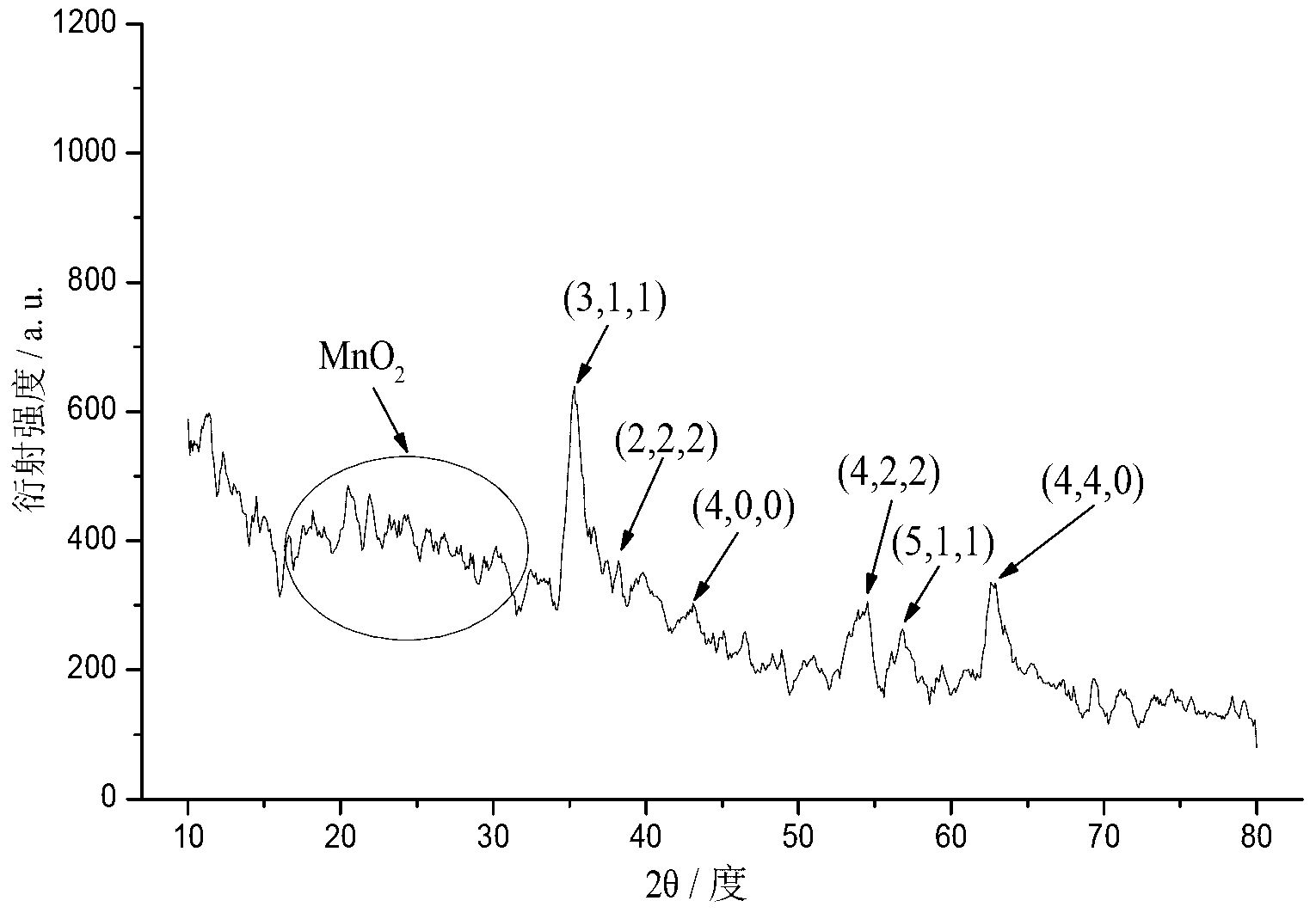

[0017] Fe 3 o 4 MnO 2 Preparation of Composite Nanomaterials (Z. Zhao, J. Liu, F. Cui, H. Feng and L. Zhang, J. Mater. Chem., 2012, 22, 9052.):

[0018] Place the beaker containing 100?mL ultrapure water in a water b...

Embodiment 1

[0020] After grinding the graphene oxide into pieces, weigh 0.1?g and add it into 100?mL PBS buffer solution for 1-2?h to obtain a uniform graphene oxide solution; take 0.2?g Fe 3 o 4 MnO 2 The composite nanoparticles were dispersed in 100?mL graphene oxide solution, ultrasonicated for 10 min, and the composite nanosheets were dispersed.

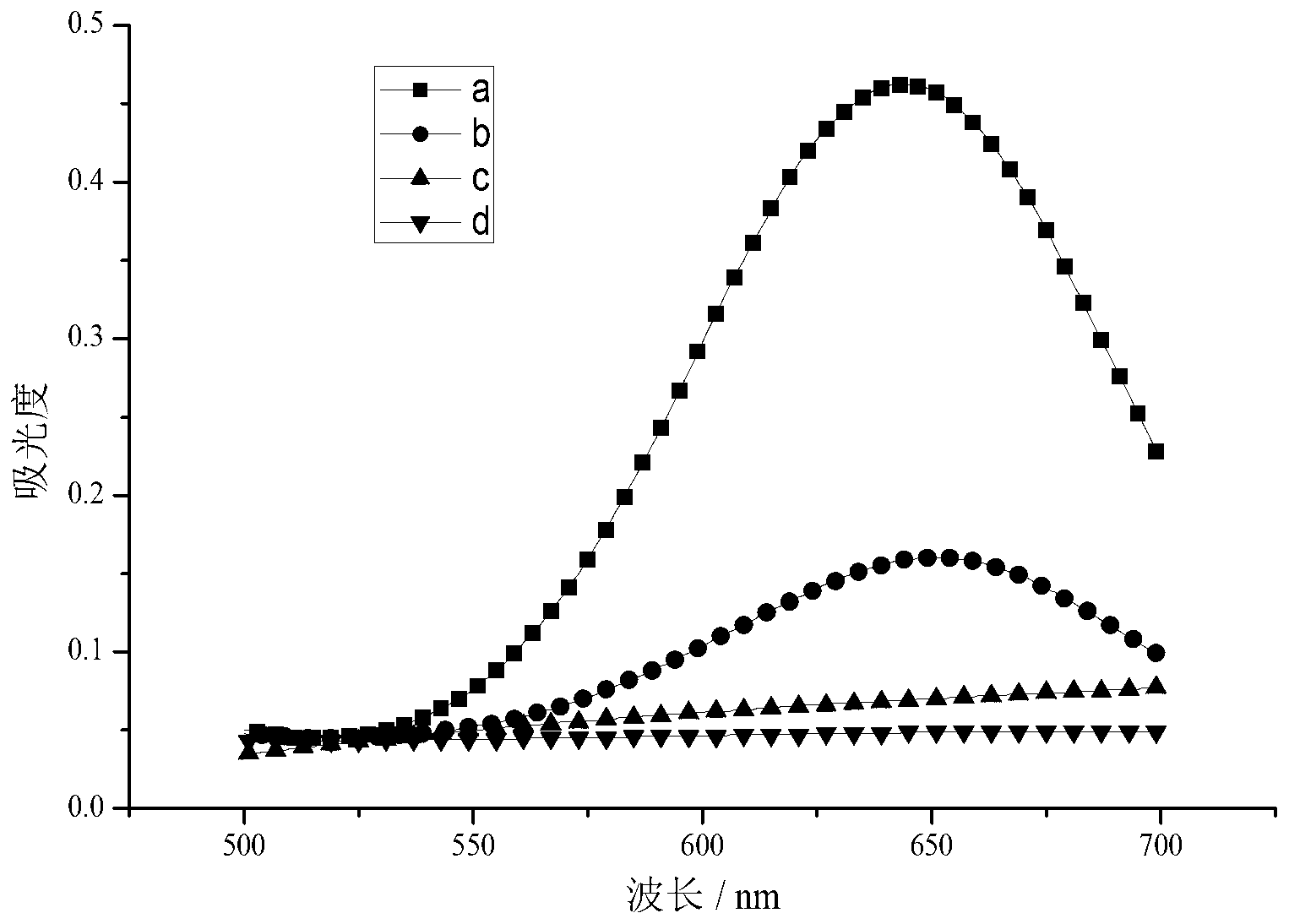

[0021] Peroxidase Activity Test of Inorganic Nanocomposite Particles

[0022] 1) At room temperature, the GO-Fe 3 o 4 MnO 2 After ultrasonic dispersion of inorganic composite nanoparticles, 20?μL of the solution was taken and added to 1.8?mL PBS buffer solution, and its absorbance in the range of 500-700?nm was measured as the background. Add 100 μL of chromogenic solution A and 200 μL of chromogenic solution B to the upper solution in sequence, and measure their absorption in the range of 500 to 700 μnm after reacting for 5 to 6 minutes.

[0023] 2) At room temperature, the Fe 3 o 4 MnO 2 After ultrasonic dispersion of inorganic comp...

Embodiment 2

[0028] After grinding the graphene oxide into pieces, weigh 0.4?g and add it into 100?mL PBS buffer solution for 1-2?h to obtain a uniform graphene oxide solution; take 0.8g Fe 3 o 4 MnO 2 Composite nanoparticles are dispersed in 100?mL graphene oxide solution, ultrasonicated for 10 minutes, and composite nanosheets are dispersed to obtain composite nanosheets with a side length of 40-70nm, which can effectively catalyze TMB, and the catalytic activity is better than that of graphene oxide or Fe 3 o 4 MnO 2 nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com