Graphene and vanadate composite nano-fiber photocatalyst and preparation method thereof

A technology of composite nanofibers and photocatalysts, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as mutual solubility and undiscovered problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

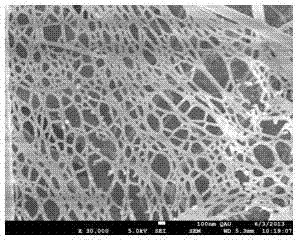

Image

Examples

Embodiment 1

[0021] (1) Add 1 mmol lanthanum nitrate (La(NO 3 ) 3 ) and 0.5g of polyvinylpyrrolidone were dissolved in 5ml of absolute ethanol, and then 20mg of graphene powder was immersed in it, stirred well and then ultrasonically dispersed for 30 minutes to obtain liquid A. Dissolve 1 mmol of vanadyl acetylacetonate in 5 ml of absolute ethanol to obtain liquid B. Add liquid B to liquid A drop by drop, and stir thoroughly for 4 hours to make a spinning solution.

[0022] (2) The above spinning solution is electrospun into filaments through an electrospinning device to obtain a composite nanofiber felt; the specific steps are:

[0023] Draw the spinning solution into the syringe (capacity 5-20ml is acceptable), the advance speed of the syringe is controlled by a micro constant flow pump, the needle of the syringe (metal material, inner diameter 0.6-1.2mm) is facing down and connected to the positive pole of the high-voltage power supply, and the fiber collecting plate ( Metal thin pla...

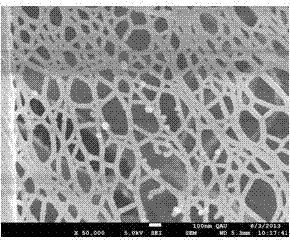

Embodiment 2

[0027] (1) Add 1mmol cerium nitrate (Ce(NO 3 ) 3 ) and 0.75g of polyvinylpyrrolidone were dissolved in 5ml of absolute ethanol, and then 30mg of graphene powder was immersed in it, stirred well and then ultrasonically dispersed for 30 minutes to obtain liquid A. Dissolve 1 mmol of vanadyl acetylacetonate in 5 ml of absolute ethanol to obtain liquid B. Add liquid B to liquid A drop by drop, and stir thoroughly for 6 hours to make a spinning solution;

[0028] (2) The above-mentioned spinning solution was electrospun into filaments through an electrospinning device, and a composite nanofiber mat containing graphene, cerium vanadate and polyvinylpyrrolidone was obtained according to the specific process described in step (2) of Example 1.

[0029] (3) Aging the fiber mat obtained in step (2) in the air for 16 hours, and then roasting at 500-600°C for 4 hours in an air atmosphere to remove polyvinylpyrrolidone (PVP), and obtain graphene and cerium vanadate (CeVO 4 ) composite n...

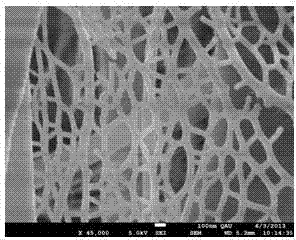

Embodiment 3

[0032] (1) Add 1mmol of praseodymium nitrate (Pr(NO 3 ) 3) and 1g of polyvinylpyrrolidone were dissolved in 5ml of absolute ethanol, and then 20mg of graphene powder was immersed in it, stirred well and then ultrasonically dispersed for 30 minutes to obtain liquid A. Dissolve 1 mmol of vanadyl acetylacetonate in 5 ml of absolute ethanol to obtain liquid B. Add liquid B to liquid A drop by drop, and stir thoroughly for 7 hours to make a spinning solution.

[0033] (2) The above-mentioned spinning liquid is electrospun into filaments through an electrospinning device, and a composite nanofiber mat containing graphene, praseodymium vanadate and polyvinylpyrrolidone is obtained according to the specific process described in step (2) of Example 1.

[0034] (3) Aging the fiber mat obtained in step (2) in the air for 24 hours, and then roasting it in an air atmosphere at 500-600°C for 6 hours to remove polyvinylpyrrolidone to obtain graphene and praseodymium vanadate (PrVO 4 ) com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com