Preparation method of graphene oxide wrapped titania microsphere photocatalyst

A technology of graphene wrapping and titanium dioxide, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of wide band gap and limited application, and achieve easy operation, low energy consumption, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

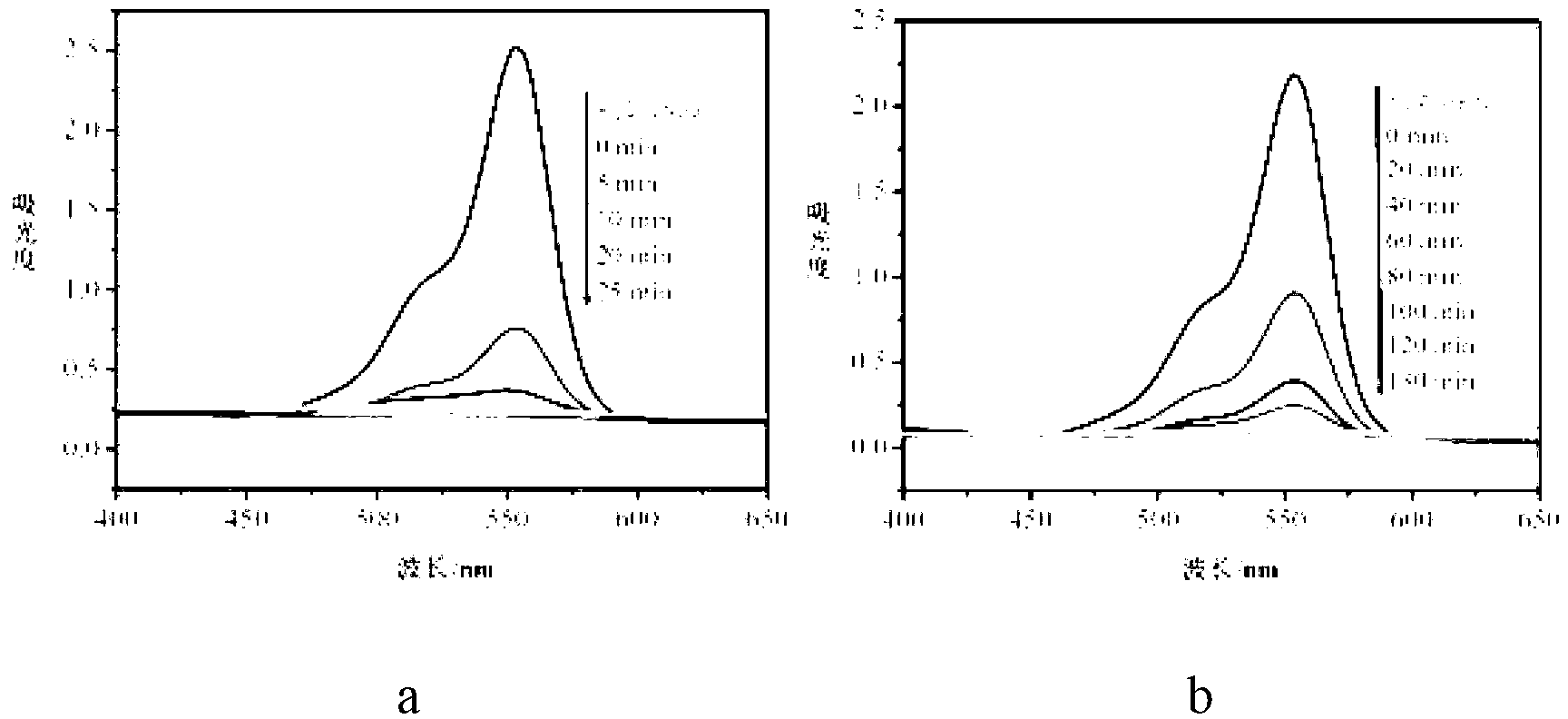

Examples

Embodiment 1

[0036]Add 115mL of 98% concentrated sulfuric acid into a dry beaker, cool to about 0°C, add 5g of natural flake graphite, 5g of sodium nitrate, and 15g of potassium permanganate in sequence while stirring. Control the reaction temperature at 10-30°C, stir for 3 hours, then place the beaker of the above solution in a constant temperature water bath at about 35°C, and continue stirring for 30 minutes when the reaction temperature rises to about 35°C. Finally, control the reaction temperature within 100°C, add deionized water dropwise, and continue to stir for 30 minutes, with a dropping rate of 0.3-0.5mL / s. Finally, a mixed solution consisting of an appropriate amount of 30% hydrogen peroxide and 50 mL of deionized water was added. The ratio of hydrogen peroxide and deionized water added is 1:5. Centrifuge and wash with water while hot to obtain a yellow-brown mud. Dry the above mud, weigh 0.2 g and disperse it in deionized water, then continue to sonicate for 3 hours, and fin...

Embodiment 2

[0038] Add 115mL of 98% concentrated sulfuric acid into a dry beaker, cool to about 0°C, add 5g of natural flake graphite, 5g of sodium nitrate, and 15g of potassium permanganate in sequence while stirring. Control the reaction temperature at 10-30°C, stir for 3 hours, then place the beaker of the above solution in a constant temperature water bath at about 35°C, and continue stirring for 30 minutes until the reaction temperature rises to about 35°C. Finally, control the reaction temperature within 100°C, add deionized water dropwise, and continue to stir for 30 minutes, with a dropping rate of 0.3-0.5mL / s. Finally, a mixed solution consisting of an appropriate amount of 30% hydrogen peroxide and 50 mL of deionized water was added. The ratio of hydrogen peroxide and deionized water added is 1:1. Centrifuge and wash with water while hot to obtain a yellow-brown mud. Dry the above mud, weigh 0.2 g and disperse it in deionized water, then continue to sonicate for 3 hours, and f...

Embodiment 3

[0040] Add 115mL of 98% concentrated sulfuric acid into a dry beaker, cool to about 0°C, add 5g of natural flake graphite, 5g of sodium nitrate, and 15g of potassium permanganate in sequence while stirring. Control the reaction temperature at 10-30°C, stir for 3 hours, then place the beaker of the above solution in a constant temperature water bath at about 35°C, and continue stirring for 30 minutes when the reaction temperature rises to about 35°C. Finally, control the reaction temperature within 100°C, add deionized water dropwise, and continue to stir for 30 minutes, with a dropping rate of 0.3-0.5mL / sec. Finally, a mixed solution consisting of an appropriate amount of 30% hydrogen peroxide and 50 mL of deionized water was added. The ratio of hydrogen peroxide and deionized water added is 1:10. Centrifuge and wash with water while hot to obtain a yellow-brown mud. Dry the above mud, weigh 0.2 g and disperse it in deionized water, then continue to sonicate for 3 hours, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com