Photocatalytic reactor for increasing photocatalytic degradation rate of methane and application of photocatalytic reactor

A photocatalytic reactor, degradation rate technology, applied in chemical instruments and methods, chemical/physical/physical-chemical processes of applying energy, separation of dispersed particles, etc., can solve the problems of low methane degradation rate and low use of ultraviolet lamps, Achieve the effects of low conversion cost, increased photocatalytic degradation rate of methane, and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

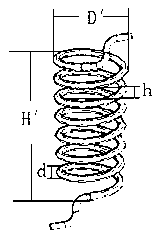

[0052] A photocatalytic reactor that can increase the photocatalytic degradation rate of methane, the schematic diagram of which is shown in Figure 1a As shown, the reactor body 4 comprising the upper opening, the cover plate 11 of the reactor, the ultraviolet light source 5, and the quartz coil 3;

[0053] The reactor body 4 is cylindrical, with an upper opening, made of heat-resistant glass, with an inner diameter of D=10cm, a height of H=32cm, and an effective volume of about 2.51L;

[0054] The reactor cover plate 11 matches the shape of the upper opening of the reactor body 4, and can be sealed and flexibly connected with the reactor body 4, and the material is frosted glass;

[0055] Described reactor cover plate 11 is provided with a gas outlet 1, and gas outlet 1 is provided with a d=0.6cm and is the elbow of 90 °, connects an elastic good latex tube and is used for getting gas to detect the concentration of methane in the gas;

[0056] The quartz coil 3 is vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com