Sugar-containing porphyrin complexation photosensitizer and preparation method thereof

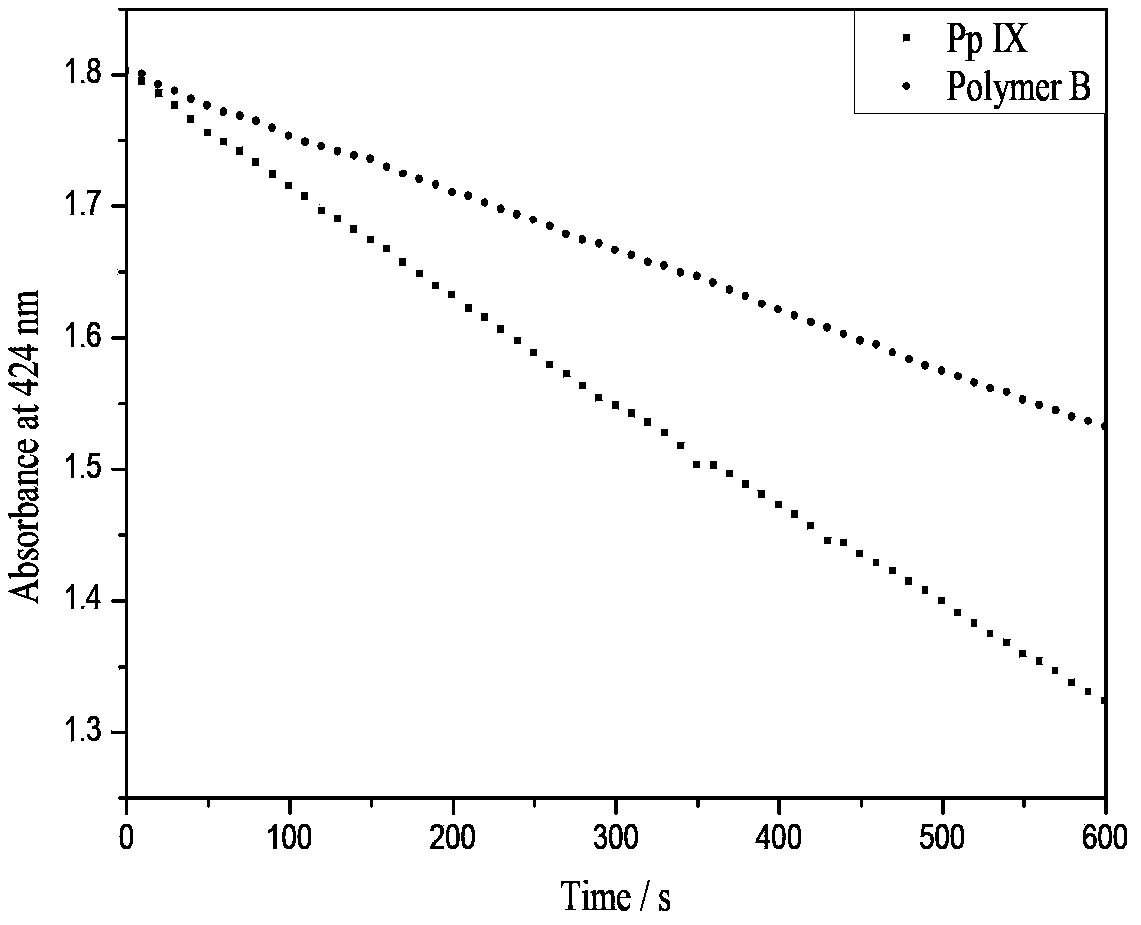

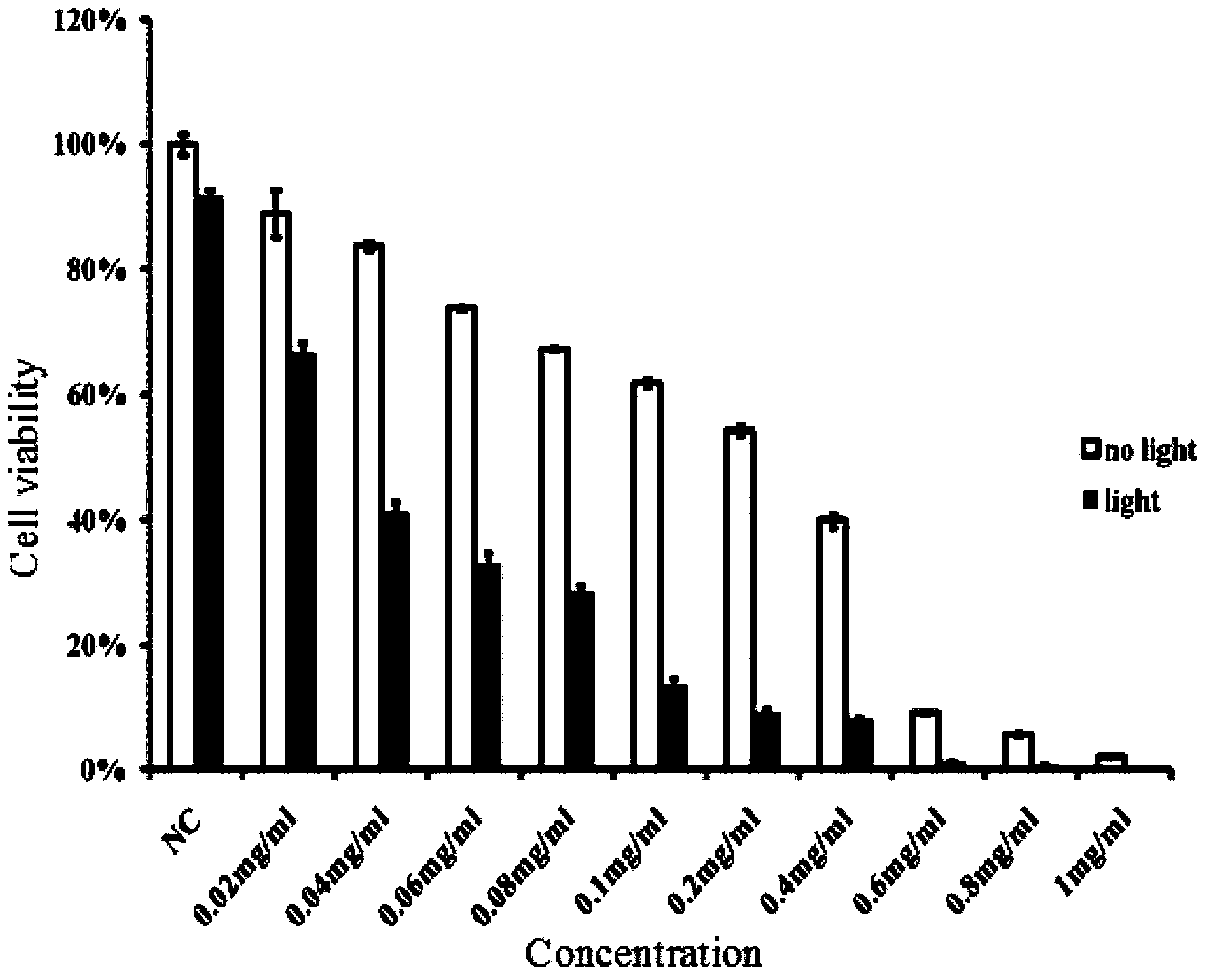

A photosensitizer and porphyrin technology, applied in the field of complexed porphyrin sugar-containing photosensitizers and the preparation thereof, can solve the problems of complex composition of porphyrin oligomer mixture, poor water solubility of porphyrin, influence on stability and the like, and achieve economical production. cost, improve water solubility, and promote the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

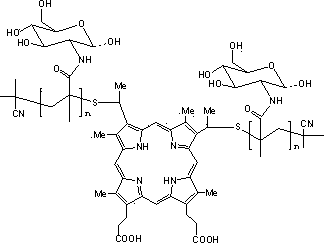

[0037] A preparation method of a complex porphyrin sugar-containing photosensitizer, comprising the steps of:

[0038] 1) Using sugar-containing monomer 2-methacrylamidoglucopyranose, initiator azobisisobutyronitrile, and chain transfer agent α-dithionaphthoic acid isobutyronitrile for reversible addition-fragmentation chain transfer polymerization , obtaining a sugar-containing polymer with a regular structure and a controllable molecular weight, wherein the mass ratio of sugar-containing monomers, initiators, and chain transfer agents is 323:1:7;

[0039] 2) Mix the sugar-containing polymer obtained in step 1) with porphyrin, add catalyst sodium amalgam, and then synthesize a complex porphyrin sugar-containing photosensitizer through a one-pot method, wherein the sugar-containing polymer and porphyrin The mass ratio is 670:7, and excess catalyst sodium amalgam is used.

Embodiment 1

[0041] 1) Preparation of sugar-containing polymers: Add 0.84 g of 2-methacrylamidoglucopyranose, 2.6 mg of initiator azobisisobutyronitrile, and 18.26 mg of chain transfer agent α-dithio Isobutyronitrile naphthoate, the solvent is N,N-dimethylacetamide; then add a magnetic stirrer, pass through nitrogen for 10 minutes to remove oxygen, seal it with a gas lamp under the protection of nitrogen, and place it in an oil bath at 70°C React for 24 hours, dilute with N,N-dimethylformamide after opening the tube, then precipitate with methanol, and dry under vacuum at room temperature to obtain a sugar-containing polymer;

[0042] 2) Dissolve 0.6 mM porphyrin in freshly prepared 0.75 mL, 0.06 M potassium hydroxide solution; flush the above solution with nitrogen gas and reduce with 1.5 g sodium amalgam until little or no fluorescence is detected under UV light, The above solution was immediately mixed with an equal volume of 0.2M sodium acetate buffer containing 0.8 mM of the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com