Process method for preparing soft element and soft substrate on CVD (chemical vapor deposition) graphene

A technology of flexible substrates and flexible devices, which is applied in the direction of electrical solid devices, semiconductor devices, semiconductor/solid device manufacturing, etc., to achieve the effects of reducing costs, shortening process flow, and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

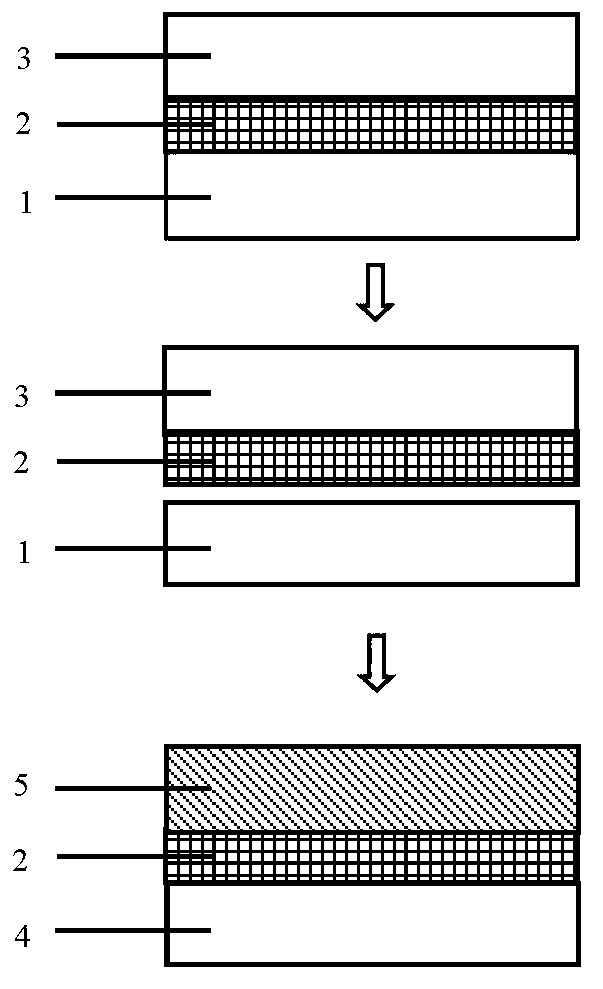

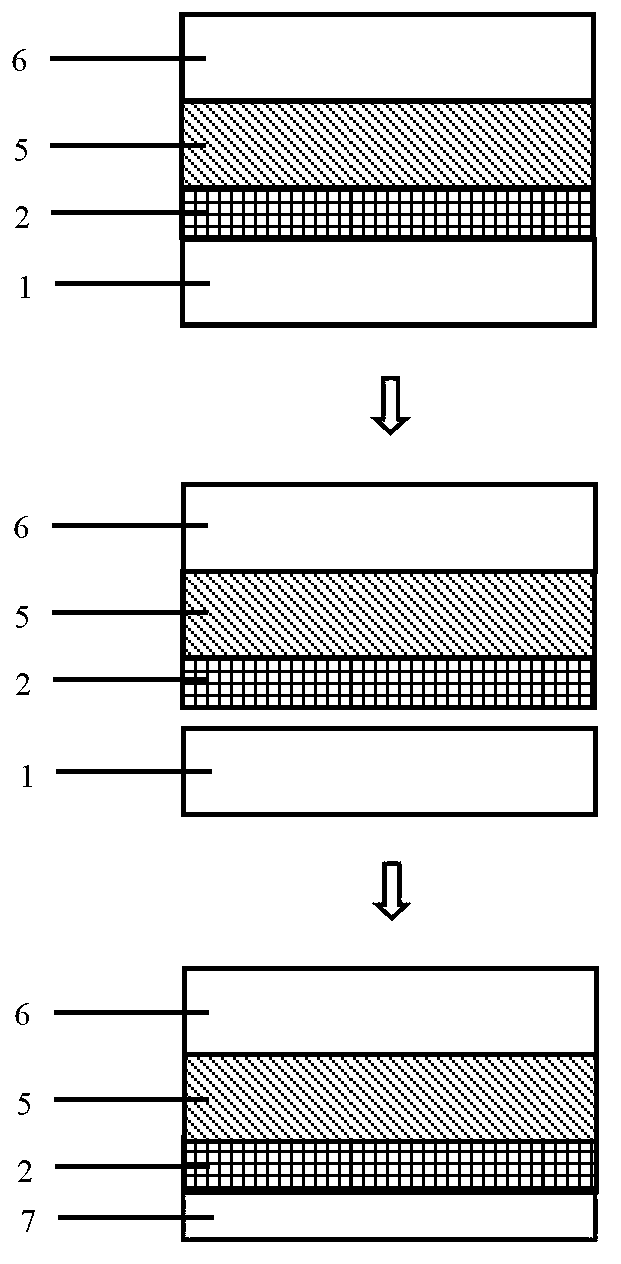

[0019] Here we take OLED as an example for description, and the process flow refers to the attachment Figure 1-3 . A 100 μm thick polycrystalline copper sheet is used as a metal catalyst substrate sheet (1 in the drawing) to grow graphene (2 in the drawing). In traditional crafts (see figure 1 ), the organic protective film 3 used for transfer is PMMA (thickness less than 1 μm) that is spin-coated and dried; the conventional non-spin-coated flexible new substrate 4 is a PET sheet. In the process of the present invention (see figure 2 ), the flexible new substrate 6 is also PET, but it is spin-coated and baked (thickness 100μm). The graphene passivation layer 7 is epoxy resin. figure 1 with figure 2 Among them, the graphene flexible electronic device functional structure 5 on the new substrate is all OLED, from bottom to top including graphene hole injection layer, organic semiconductor layer (such as NPB, TBADN: NPB: rubrene, TBADN: NPB: DPAVBi, TBADN: DPAVBi, Bebq 2 ), Ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com