Biomass particle fuel clean combustion stove

A biomass pellet, combustion furnace technology, applied in the combustion of solid fuel, combustion equipment, steam generation and other directions, can solve the problems of reducing biomass utilization efficiency, reducing heat exchange efficiency of biomass boilers, etc., to improve thermal efficiency, combustion temperature The effect of improving the level and reducing the heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

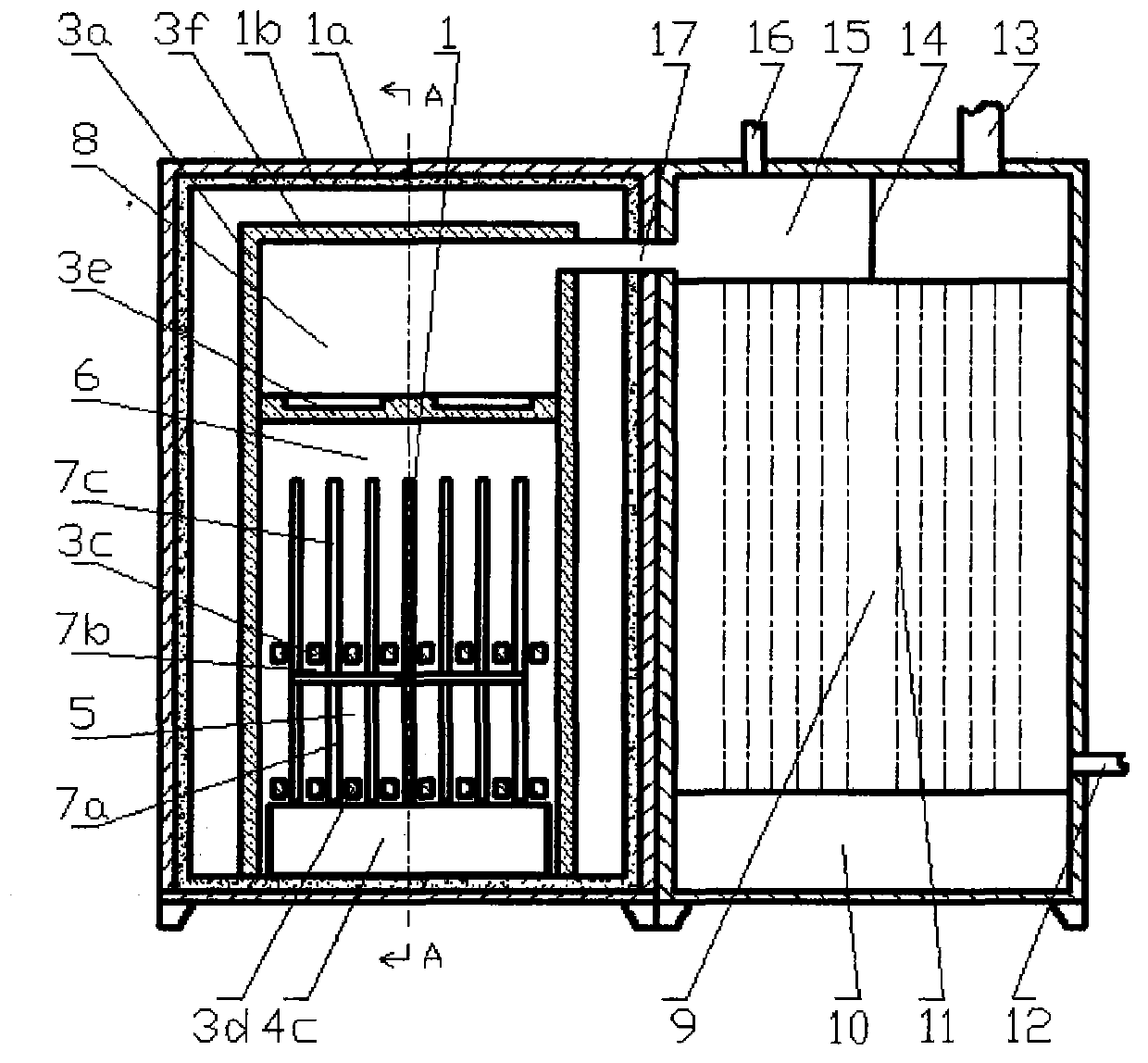

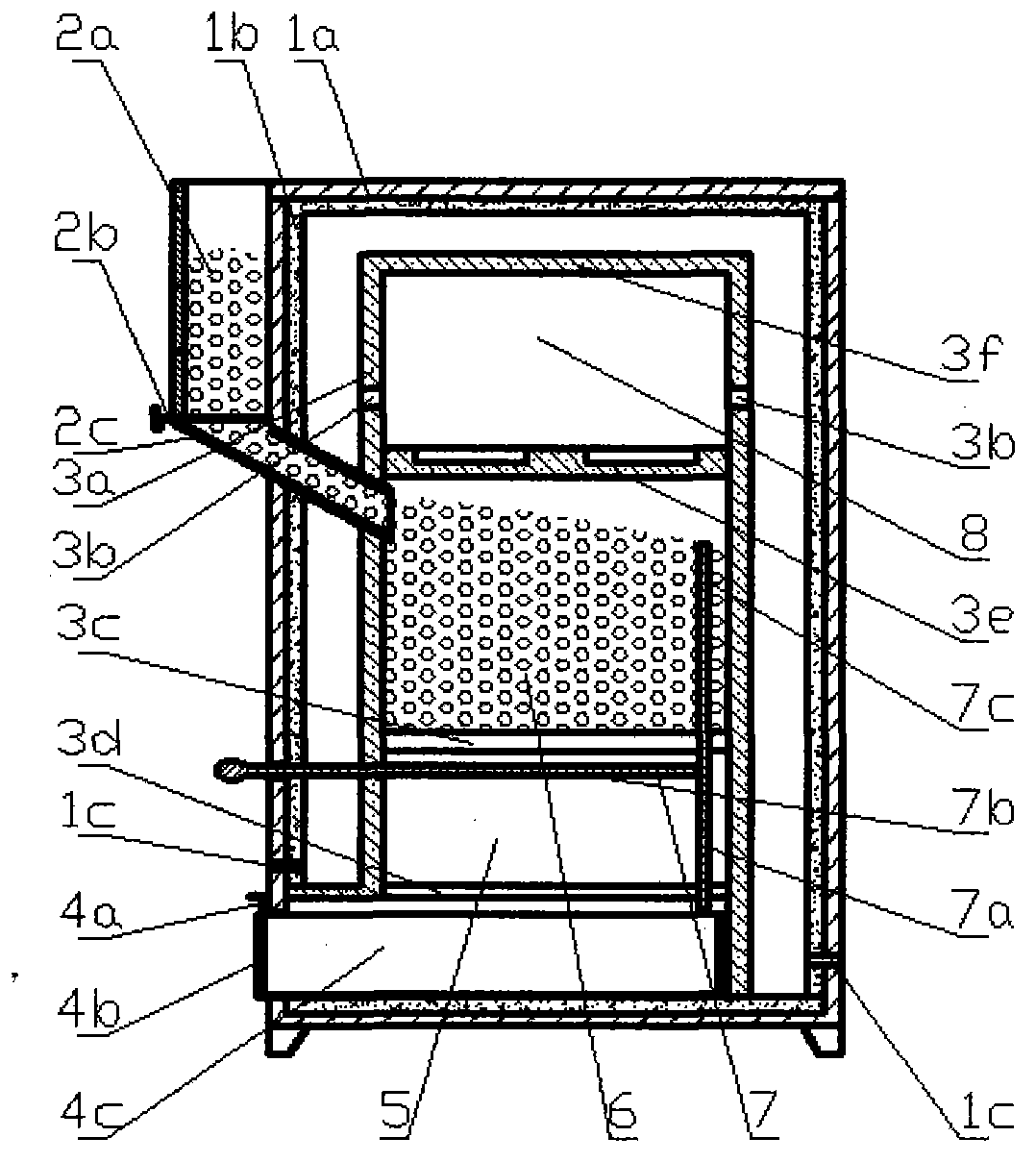

[0028] see figure 1 , figure 2 , the biomass particle fuel clean combustion boiler is a vertical structure, which is composed of a combustion furnace body 1 and a flue gas water heat exchanger 9 standing side by side. The combustion furnace body 1 is mainly composed of an outer cover 1a and an inner container 3a placed inside the outer cover 1a , the ash discharge drawer 4c placed at the bottom of the inner container 3a and penetrating with the outer wall of the outer cover 1a, the feed bin 2a fixed on the upper part of the outer wall of the outer cover 1a, and the agitator 7 inserted into the inner container 3a.

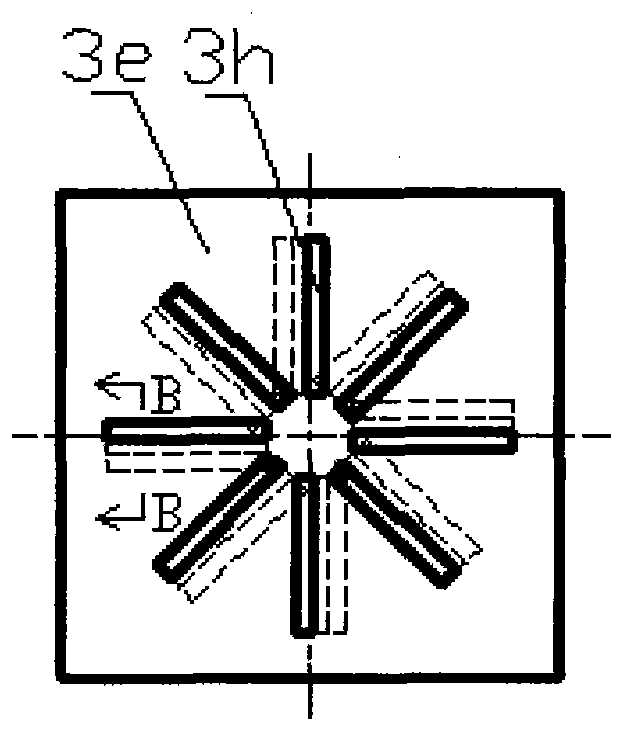

[0029] Coat one deck insulation layer 1b on the inner side of outer cover 1a. The interior of the liner 3a is divided into a gas combustion chamber 8, a gasification chamber 6 and an ash chamber 5 from top to bottom by an upper end cover 3f, a flame stabilizing plate 3e, an upper grate 3c and a lower grate 3d. Offer 3-8 inclined passages 3h radially on the flame-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com