A hollow-structured non-metallic Dewar for AC superconducting magnets

A superconducting magnet, non-metal technology, applied in the method of container discharge, gas/liquid distribution and storage, pressure vessel, etc., can solve the problem of repeated maintenance of vacuum interlayer vacuum, heavy workload, liquid nitrogen leakage, poor adhesion performance and other problems, to achieve the effect of low production cost, no eddy current loss, and high degree of vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0021] The invention is applied to the hollow structure non-metallic Dewar of AC superconducting magnets. The inner and outer cylinders and the middle cylinder are integrally cured and molded with epoxy resin and glass fiber. The Dewar cylinder has no joints and can withstand repeated impacts from low-temperature media. Good air tightness, high vacuum degree, no eddy current loss, and low production cost.

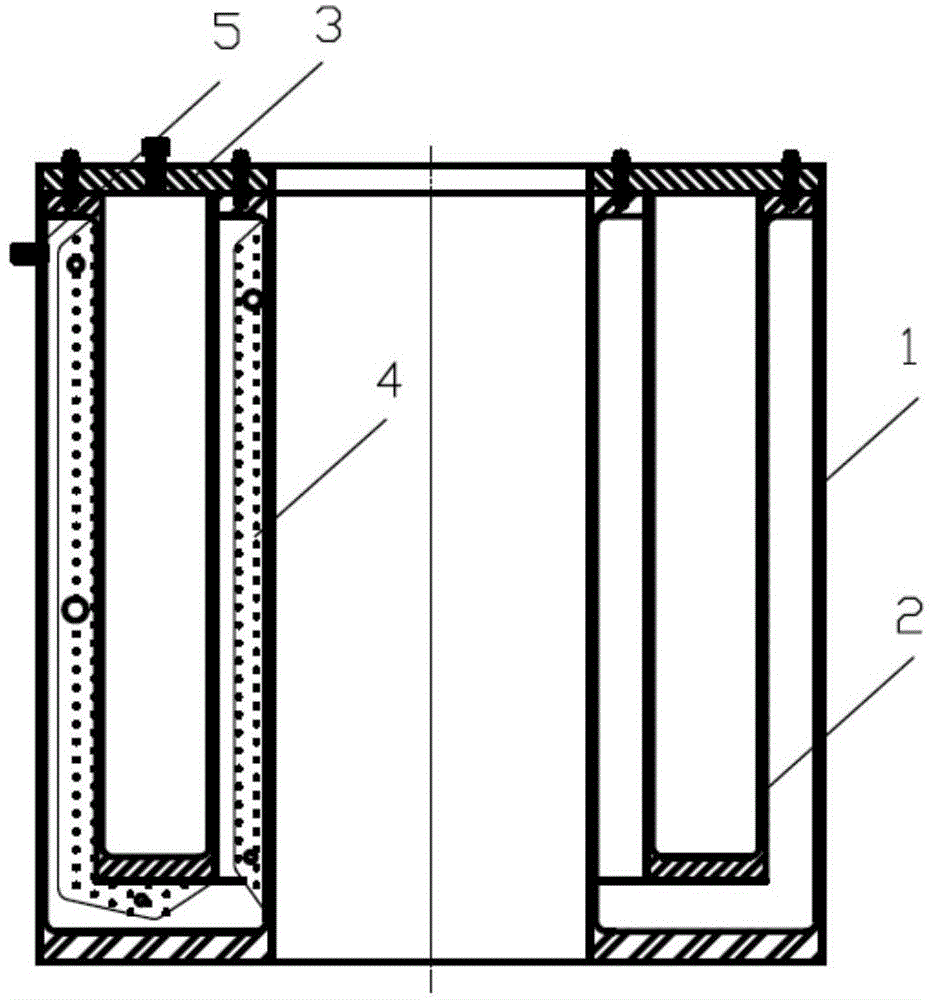

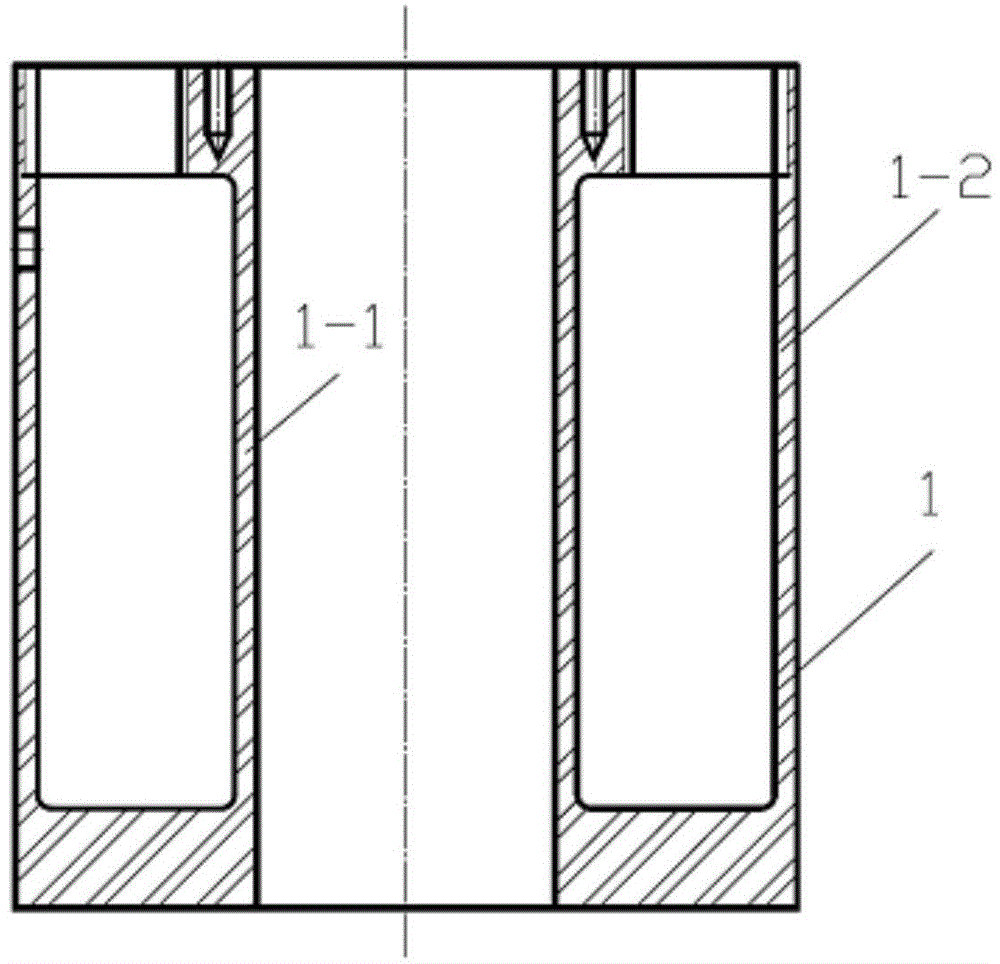

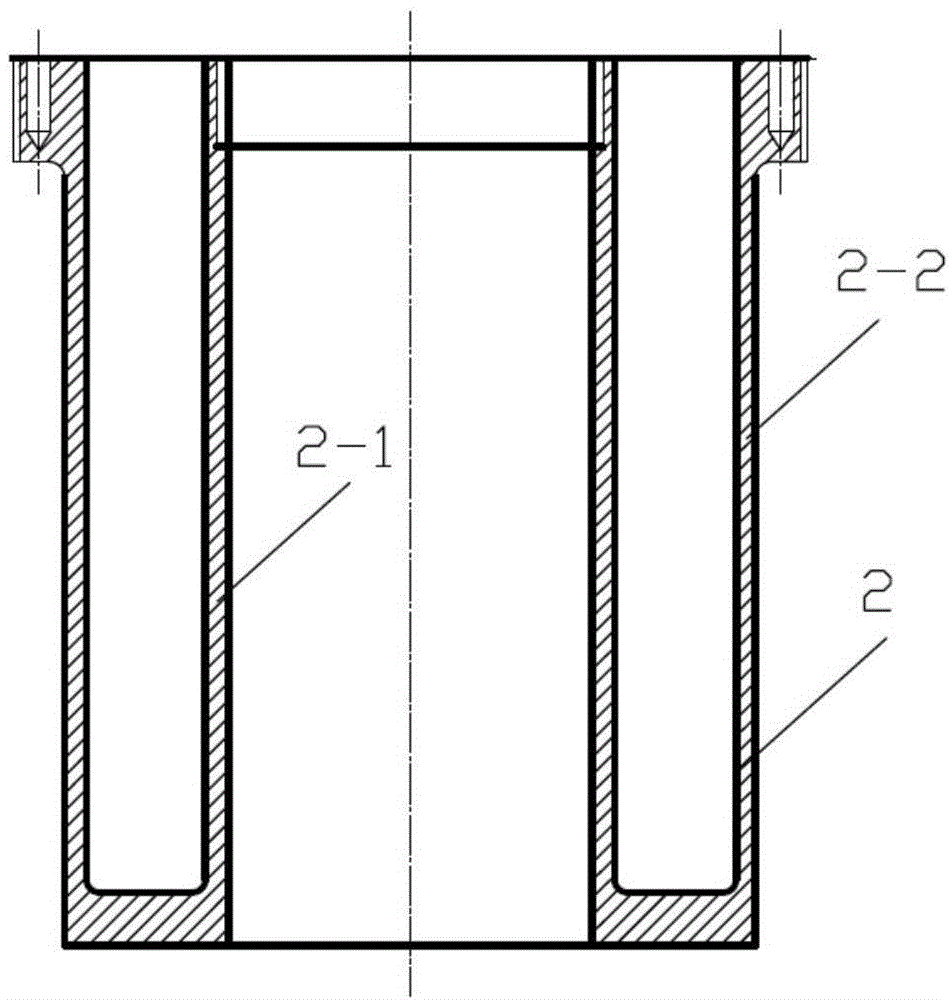

[0022] figure 1 Shown is the structural diagram of the hollow structure non-metallic Dewar of Embodiment 1. The non-metallic Dewar is composed of an inner and outer cylinder 1 , an intermediate cylinder 2 , a Dewar cover 3 , a vacuum interlayer 4 and a vacuum nozzle 5 . The inner and outer cylinders 1 and the middle cylinder 2 are both hollow structures, the middle cylinder 2 is nested inside the inner and outer cylinders 1, the vacuum interlaye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com