Oil well formation fracturing string tool string tension detection instrument

A technology of tension detection and formation pressure, which is applied in measurement, wellbore/well components, earthwork drilling and production, etc. It can solve problems such as string fracture, complicated string contact of flexible strings, and inaccurate safe fracturing pressure values, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0026] The invention is an instrument used for measuring the tension of formation fracturing pipe strings. Through the instrument mandrel and the lower joint, it can be connected to any position of the fracturing string. One string can be connected to multiple tensiometers to measure and analyze the tension of the entire string and obtain tension data with reference value. It is used for pre-evaluation and process formulation of similar fracturing processes.

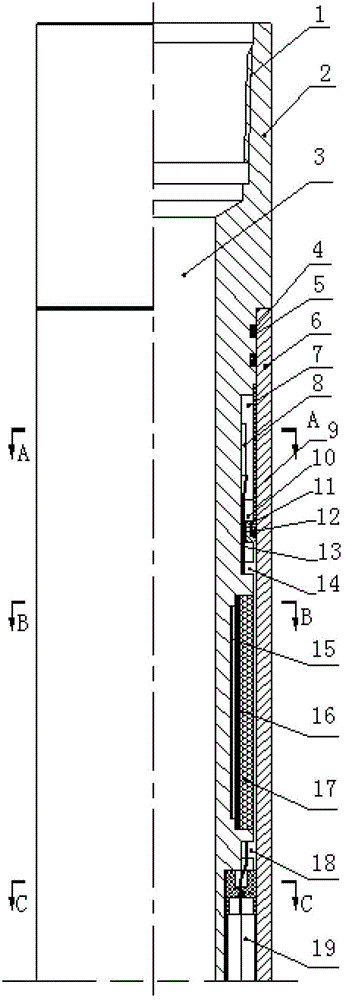

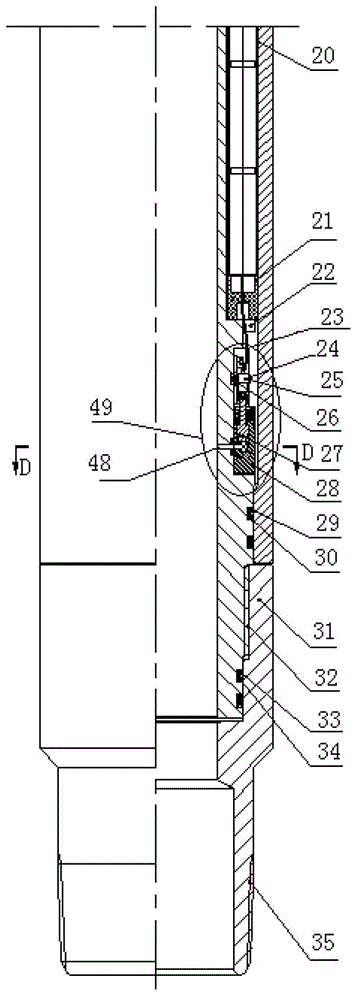

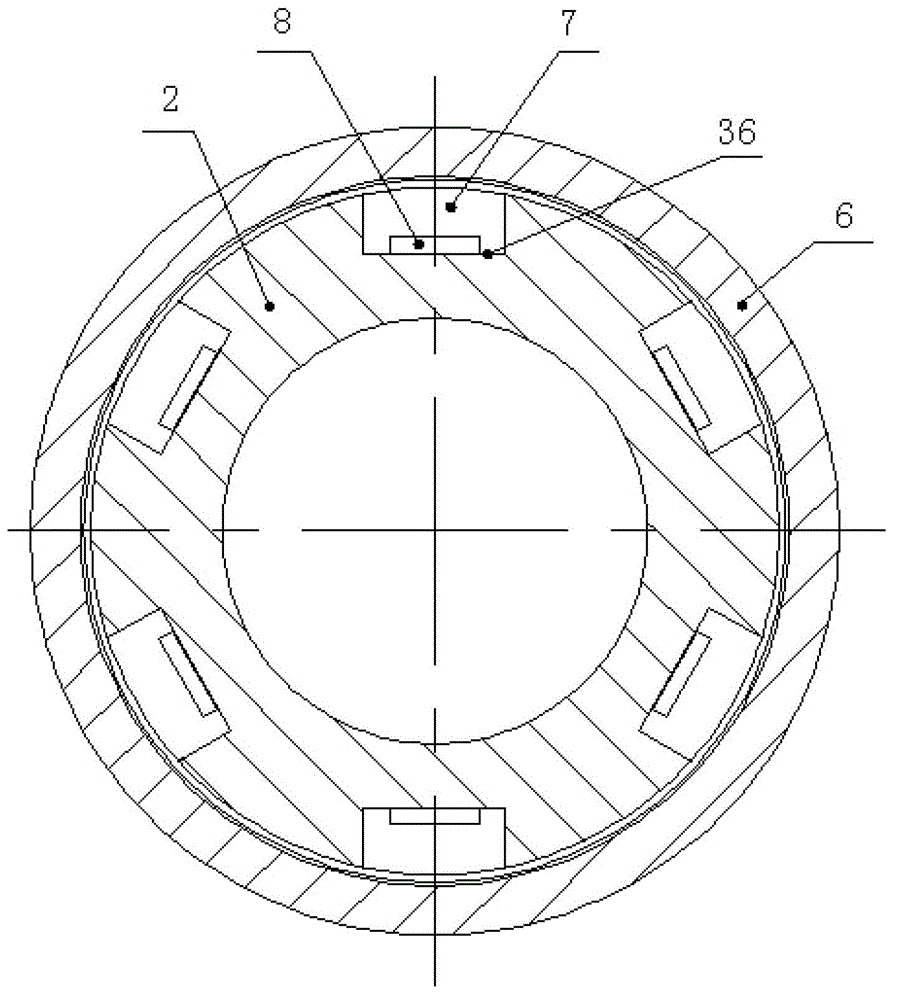

[0027] Fig. 1 (a) and Fig. 1 (b) are mechanical structural diagrams of the present invention, mainly by: mandrel 2 of tensiometer, sensor 8, pressure-resistant outer tube 6, measuring and recording circuit (circuit board 16), lithium battery (lithium The battery assembly 19), the power switch device 49 and the lower joint 31 etc. are composed.

[0028] As shown in Fig. 1(a) and Fig. 1(b)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com