Device and method for realizing integral knitting for horizontal division area structures

A regional and horizontal technology, applied in the direction of braided fabrics, textiles and papermaking, etc., can solve the problems of difficult weaving manufacturability and quality control, inability to meet design requirements at the same time, loss of processing very sensitive performance, etc., to improve weaving efficiency, High machinability and effect of reducing the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

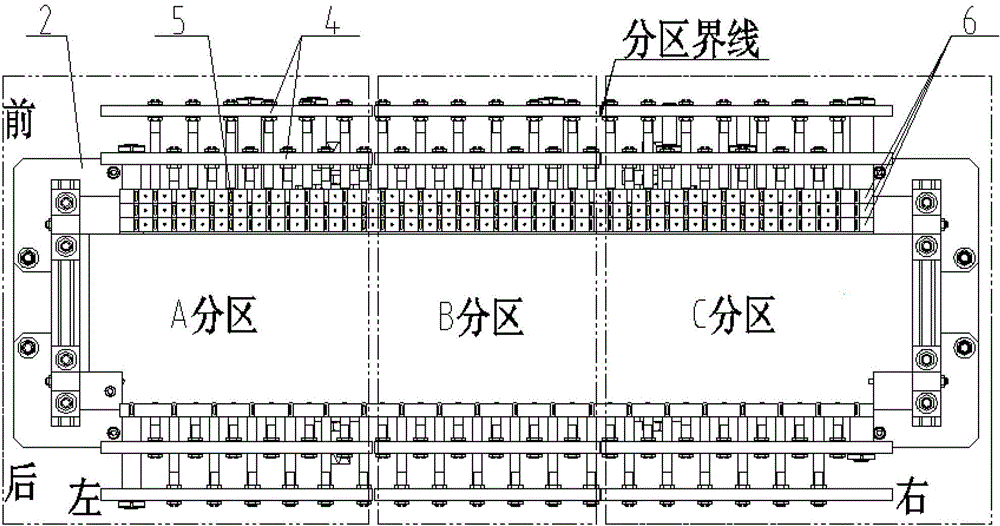

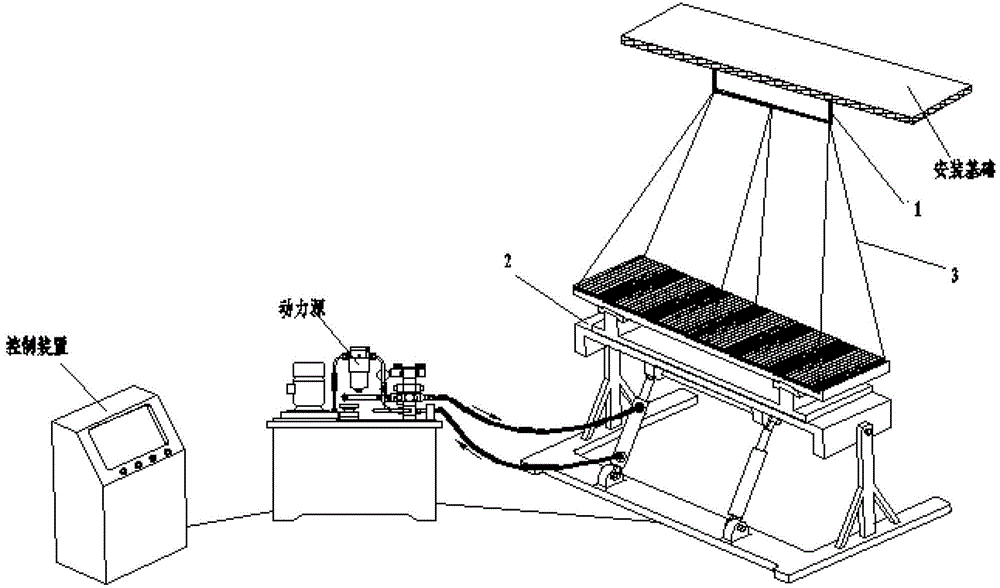

[0053] Embodiment 1: as Figure 8 As shown, the three sub-areas of A, B, and C adopt three-dimensional braided structure, corner interlocking structure, and three-dimensional braided structure respectively, and the A and C areas adopt the same row (n) and column (m) arrangement state, and n =7, m=7, n=7, m=5 in area B.

[0054] The specific operation steps are as follows:

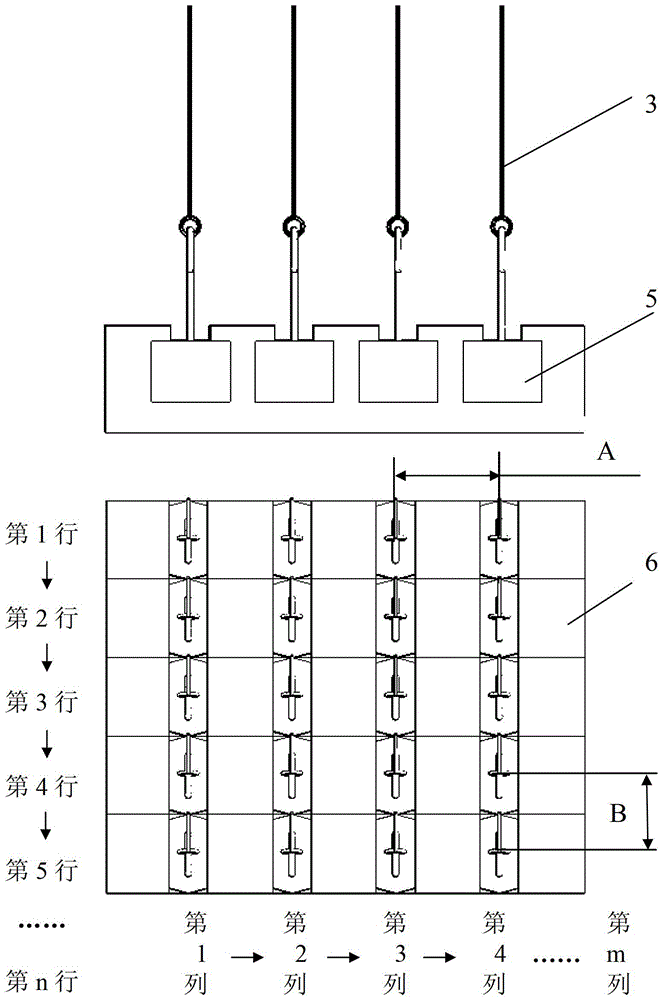

[0055] (1) Set the initial state of the partitioned knitting workbench 2 according to the requirements of the knitting structure and tie the yarn. The 1st and 7th rows of the weaving track 6 in A, B, and C areas (from the back to the front are the 1st row, the 2nd row...) The 1st row and the 7th row are set to be fixed, and the relative The motion direction of the adjacent motion track 6 is opposite, and the current and subsequent motion directions of the same motion track 6 are also opposite, and the step distance of each motion=A.

[0056] The first and seventh columns of the telescopic rod group 4 in ...

Embodiment 2

[0067] Embodiment 2: as Figure 4 As shown in (b), 4 sets of equipment that can realize the integrated weaving of horizontal sub-area structure are combined into a circle, and the three sub-areas of A, B, and C of each equipment adopt three-dimensional weaving structure, corner interlocking structure and three-dimensional interlocking structure respectively. In the braided structure, the A and C areas adopt the same row (n) and column (m) arrangement state, and n=7, m=7, and the B area's n=7, m=5.

[0068] The specific operation steps are as follows:

[0069] (1) After the weft yarn is introduced, the telescopic rod group moves in 4 rows. Introduce a weft yarn in the gap between the first row and the second row to cover the entire circumference, and then move in 5 weft yarns in the gap between the second row to the seventh row, and introduce a total of 6 weft yarns. like Figure 8 (a) shown. The telescopic rod group moves in 4 rows, the 2nd, 4th and 6th row of the retracta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com