Ultrahigh-strength titanium alloy and preparation method thereof

An ultra-high-strength, titanium alloy technology, applied in the field of ultra-high-strength titanium alloys and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

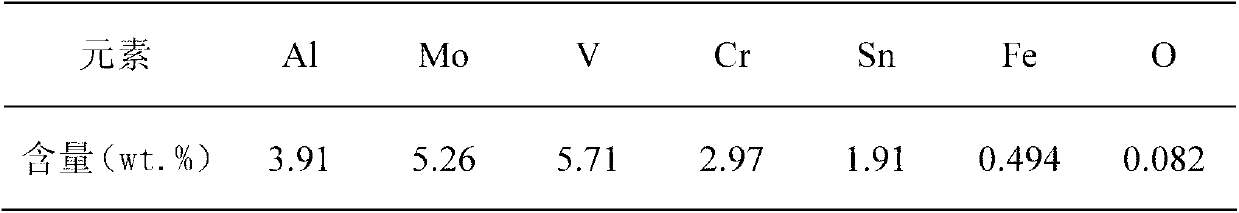

[0010] Specific Embodiment 1: In this embodiment, an ultra-high-strength titanium alloy consists of 3.0% to 5.0% Al, 4% to 6% Mo, 5% to 7% V, and 2% to 4% Cr in this embodiment , 1% to 3% of Sn, 0.5% to 1% of Fe, the balance being Ti and unavoidable impurities.

[0011] The unavoidable impurities mentioned in this embodiment are O, H, N, C, Si, etc., wherein O≤0.1%, C≤0.08%, H≤0.0005%, N≤0.02%.

[0012] The ultra-high-strength titanium alloy described in this embodiment is a Ti-3.5Al-5Mo-6V-3Cr-2Sn-0.5Fe alloy, which belongs to a nearly β-type titanium alloy. The nominal Mo equivalent of the alloy is 11.43, and the β stability coefficient is 1.43.

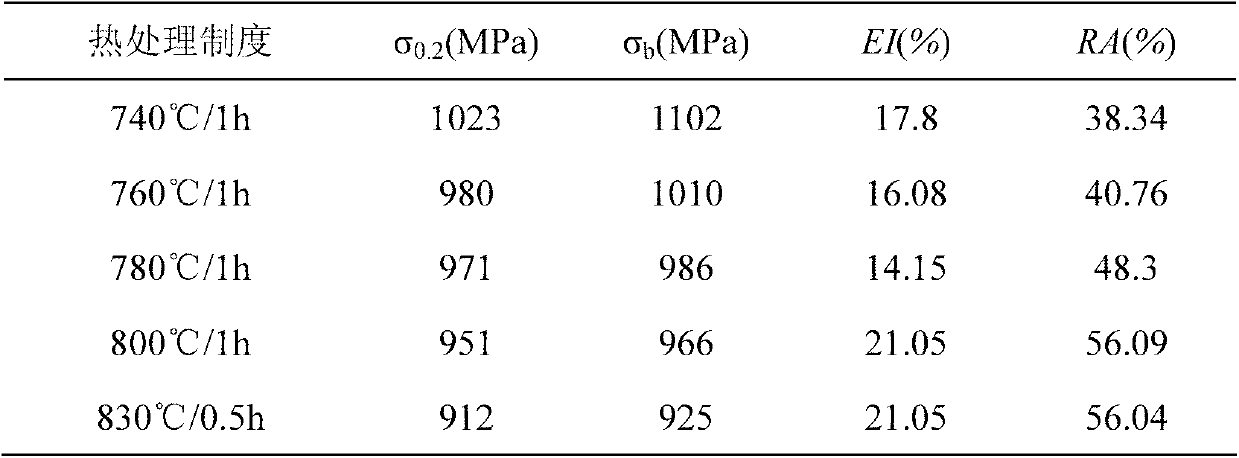

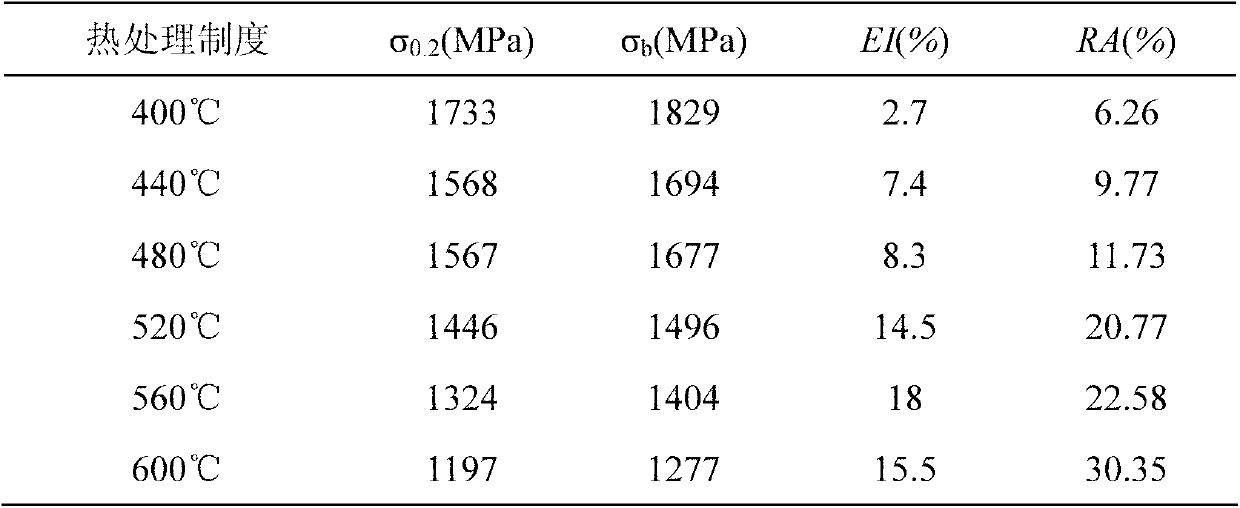

[0013] The ultra-high-strength titanium alloy described in this embodiment can achieve a tensile strength of 1496 MPa, an elongation of 14.5%, and a reduction of area of 20.77% after solid solution and aging.

[0014] The ultra-high-strength titanium alloy described in this embodiment has a maximum tensile strength of 1829MPa a...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ultra-high strength titanium alloy consists of 4.0% to 5.0% of Al, 4.5% to 6% of Mo, 6% to 7% of V, 3% to 4% of Cr, 2% to 3% of Sn, 0.5% to 1% of Fe, the balance being Ti and unavoidable impurities. Others are the same as in the first embodiment.

[0016] The unavoidable impurities mentioned in this embodiment are O, H, N, C, Si, etc., wherein O≤0.1%, C≤0.08%, H≤0.0005%, N≤0.02%.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the ultra-high strength titanium alloy consists of 4.0% Al, 5% Mo, 6% V, 3% Cr, 2% Sn, 0.5% Fe, the balance is Ti and unavoidable impurities. Others are the same as in the first or second embodiment.

[0018] The unavoidable impurities mentioned in this embodiment are O, H, N, C, Si, etc., wherein O≤0.1%, C≤0.08%, H≤0.0005%, N≤0.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com