Nanometer ultrathin coat powdery coating and preparation method

A powder coating and nano-type technology, which is applied in the direction of powder coating, coating, polyester coating, etc., can solve the problems of ultra-thin performance, leveling spraying effect, poor development, and low production efficiency. and other problems, to achieve the effects of strong practicability, excellent dispersion performance, coating film density and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

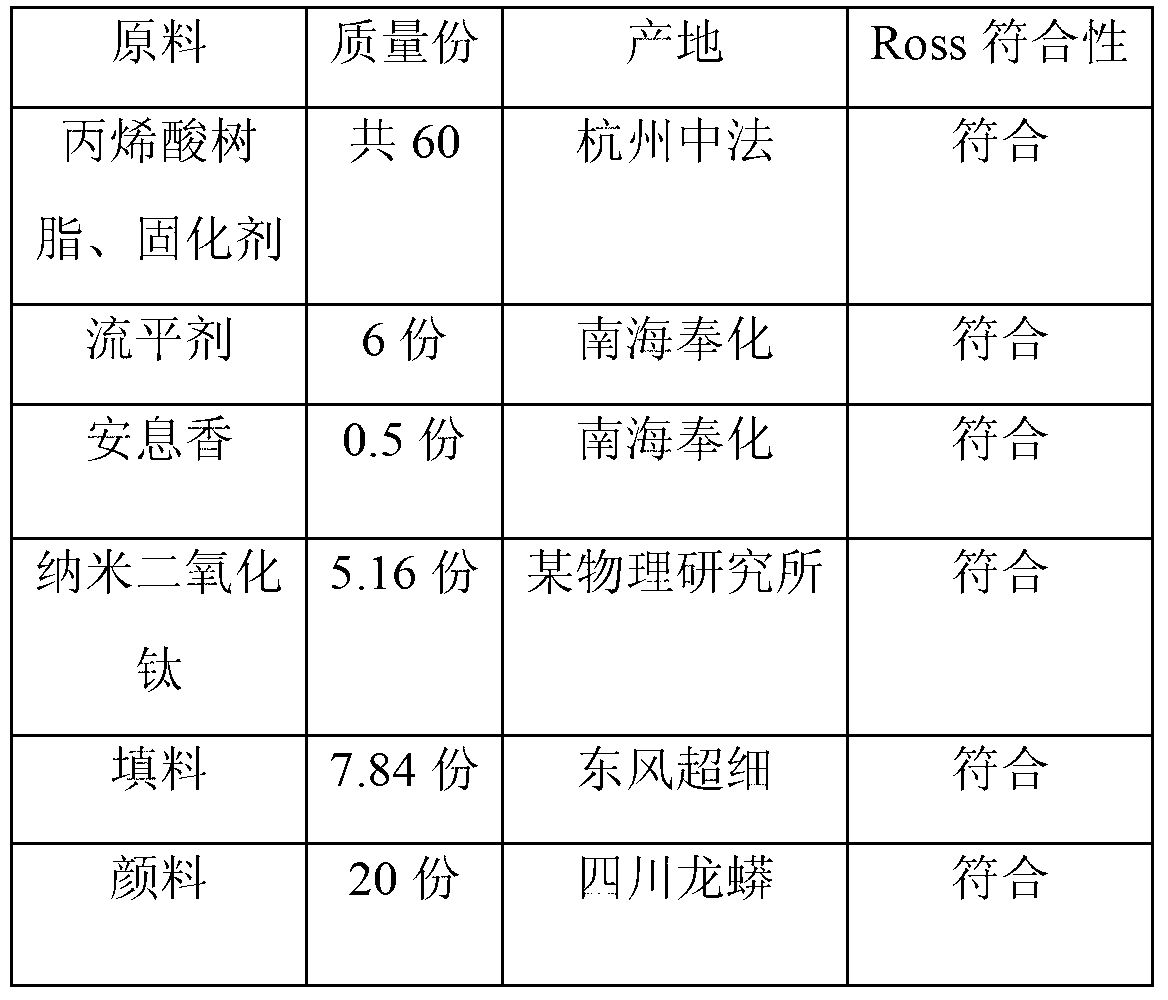

[0023] A nano-type ultra-thin coating powder coating, the weight ratio of its raw materials is composed of the following table:

[0024] Formulation of table 2 the present invention forms

[0025]

[0026] Mix the raw materials uniformly in proportion, extrude and grind the finished product. Spraying with an electrostatic spray gun to obtain a film thickness of 38um and a spraying area of 18m 2 / Kg coating.

Embodiment 2

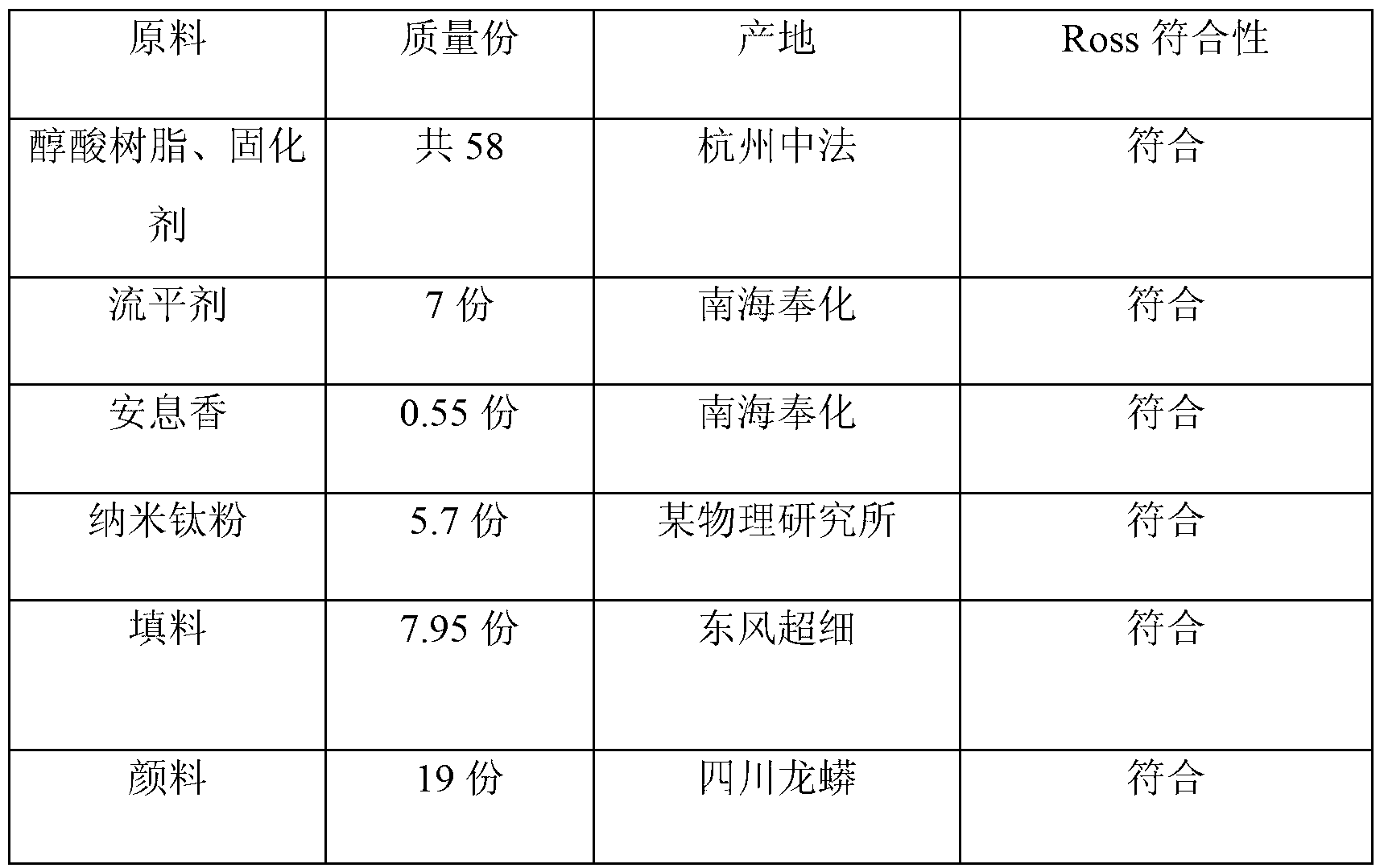

[0028] A nano-type ultra-thin coating powder coating, the weight ratio of its raw materials is composed of the following table:

[0029] Formulation of table 3 the present invention forms

[0030]

[0031] Mix the raw materials uniformly in proportion, extrude and grind the finished product. Spraying with an electrostatic spray gun to obtain a film thickness of 41um and a spraying area of 16.5m 2 / Kg coating.

Embodiment 3

[0033] A nano-type ultra-thin coating powder coating, the weight ratio of its raw materials is composed of the following table:

[0034] Formulation of table 3 the present invention forms

[0035]

[0036] Mix the raw materials uniformly in proportion, extrude and grind the finished product. Use an electrostatic spray gun to spray to obtain a film thickness of 45um and a spraying area of 15m 2 / Kg coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com