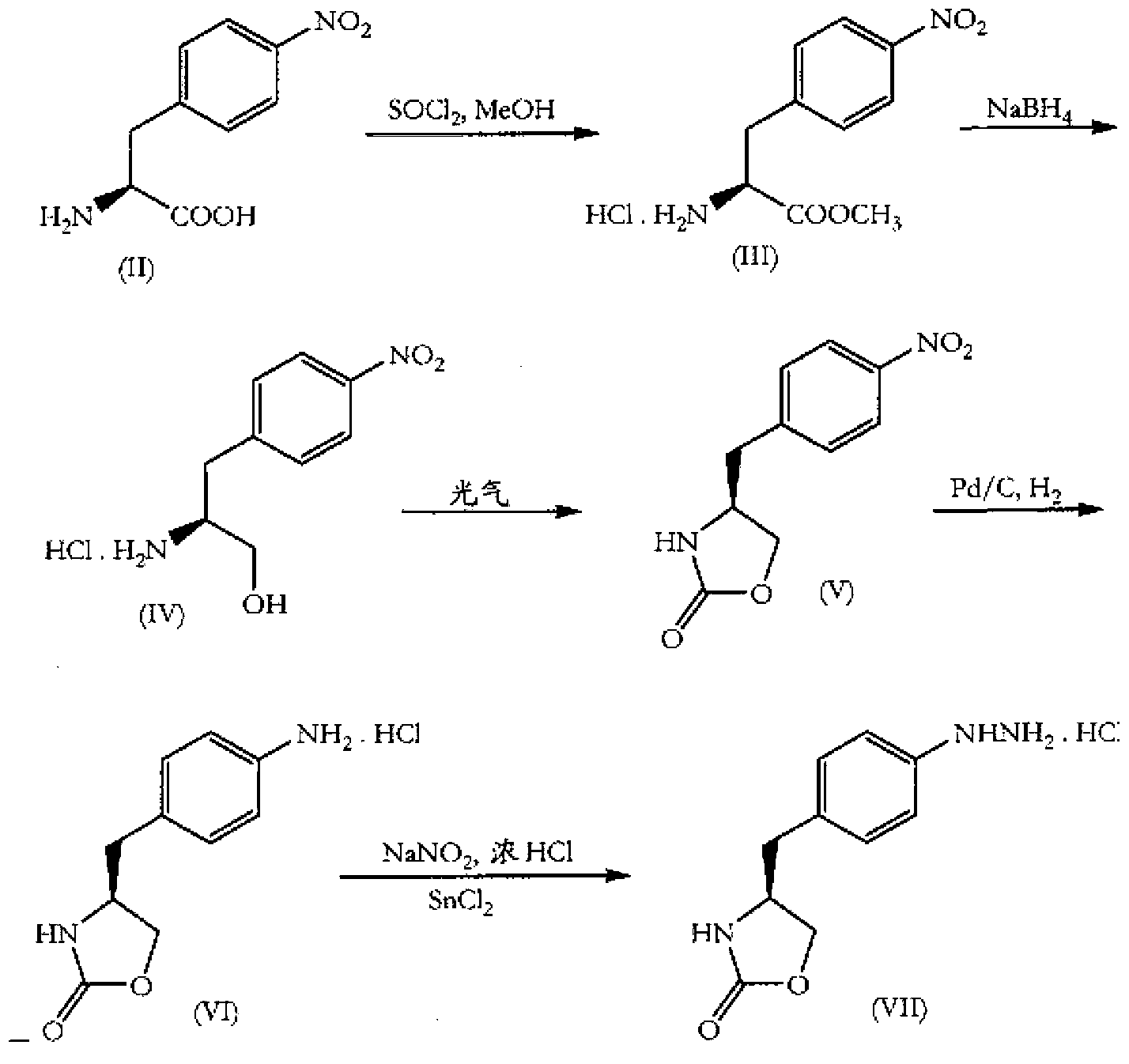

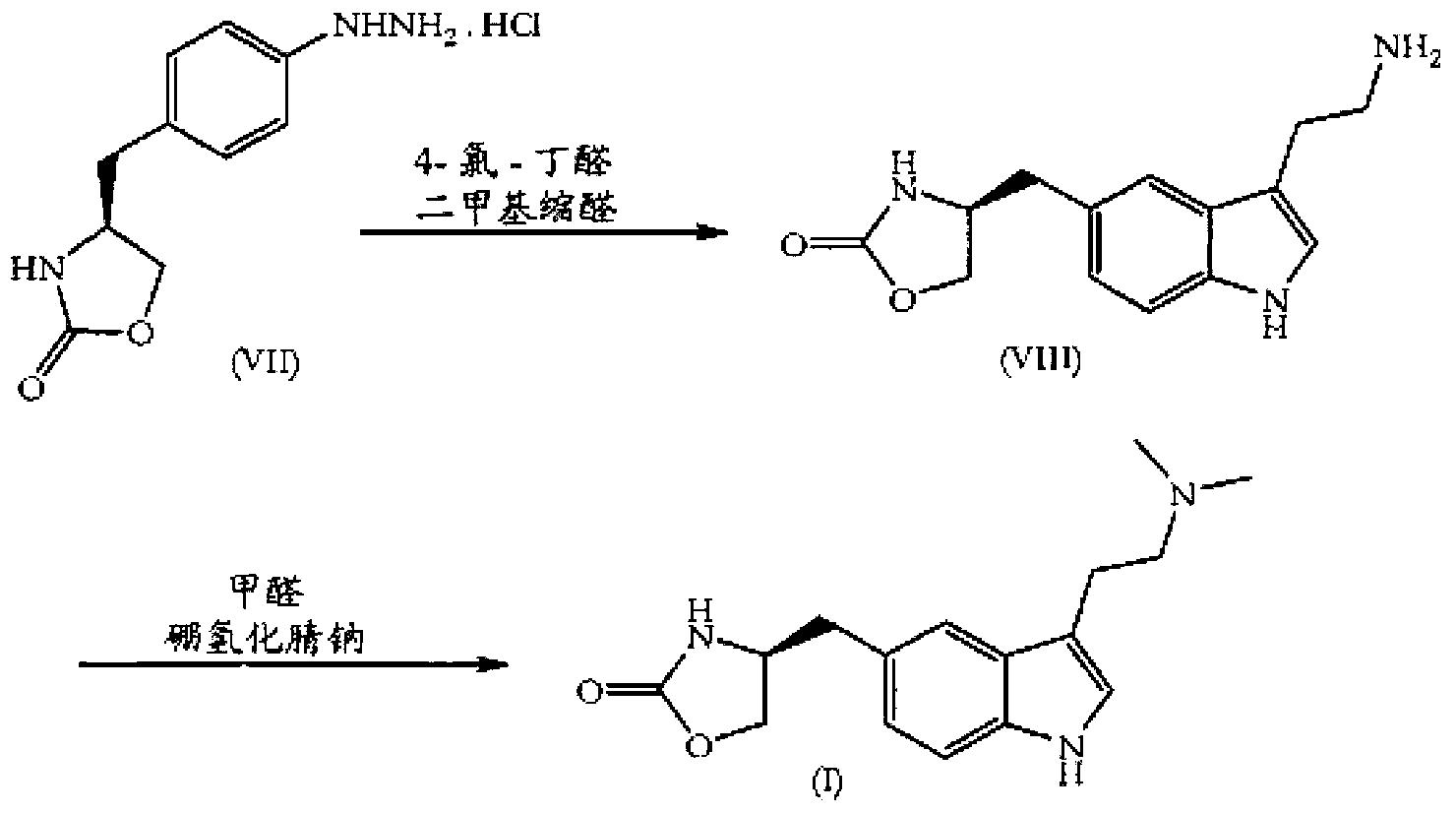

Zolmitriptan and preparation method thereof

A technology of oxazolidinone and reaction, which is applied in the field of pharmaceutical preparations and can solve problems such as lengthiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] Embodiment 1: the preparation of L-4-nitro-phenylalanine

[0105] Reaction formula:

[0106] Feeding ratio: L-phenylalanine 1kg, concentrated sulfuric acid 1700ml, concentrated nitric acid 450ml

[0107] Operation: In a reaction vessel equipped with a thermometer, add concentrated sulfuric acid according to the ratio, cool in an ice-salt bath to below 0°C and start to slowly add concentrated nitric acid dropwise. During the dropping process, control the temperature below 2°C; after dropping, control the temperature below 20°C Add L-phenylalanine in batches; after the addition, remove the ice-salt bath and let it rise to room temperature naturally, and stir for 30 minutes. Pour the reaction solution into 7L of ice water, control the temperature below 5°C while stirring, adjust the pH to 9.5-10.5 with 25% ammonia water, cool and crystallize, filter, and collect the solid; add 14L of hot water to heat and stir to dissolve the solid, and use the amount of feed Stir an...

Embodiment 2

[0108] Embodiment 2: the preparation of L-4-nitrophenylalanine methyl ester

[0109] Reaction formula:

[0110] Feed ratio: L-4-nitro-phenylalanine 720g, thionyl chloride 858ml, anhydrous methanol 3430ml

[0111] Operation: In a reaction vessel equipped with a thermometer, add anhydrous methanol according to the ratio, cool in an ice-salt bath to below 0°C and add thionyl chloride dropwise; after dropping, control the temperature below 2°C and stir for 30 minutes, then add L- 4-Nitro-phenylalanine was stirred in an ice-salt bath for 8 hours, removed from the ice bath, allowed to rise to room temperature naturally, and stirred for reaction. TLC monitors the reaction process (developing agent: chloroform: methanol = 1: 2), after the completion of the reaction (R f =0.8~0.85), use a rotary evaporator (control temperature 85±5°C) to concentrate under reduced pressure until no liquid drops out, add 750ml ice water and 1500mL ethyl acetate, and use saturated Na 2 CO 3 Soluti...

Embodiment 3

[0112] Embodiment 3: Preparation of (S)-3-(4-nitrophenyl)-2-amino-1-propanol

[0113] Reaction formula:

[0114] Feeding ratio: L-4-nitrophenylalanine methyl ester 200g, sodium borohydride 130g, methanol 2000ml, purified water 1000ml

[0115] Operation: In a reaction vessel equipped with a thermometer, add methanol and purified water according to the ratio, cool in an ice-salt bath to below 0°C, and add sodium borohydride in batches (control the reaction temperature not to exceed 2°C). After the addition is completed, add L-4-nitrophenylalanine methyl ester in batches (control the reaction temperature not to exceed 5°C). After the addition, stir and react at 0-5°C for 0.5 hours; then slowly rise to room temperature (about 20°C) , stirred for 3-5 hours; heated in a water bath to 50°C for 2-3 hours, TLC showed that the reaction was complete (developing solvent: dichloromethane: methanol = 2:1). Add 5% activated carbon to the reaction solution, decolorize at 50°C for 20 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com