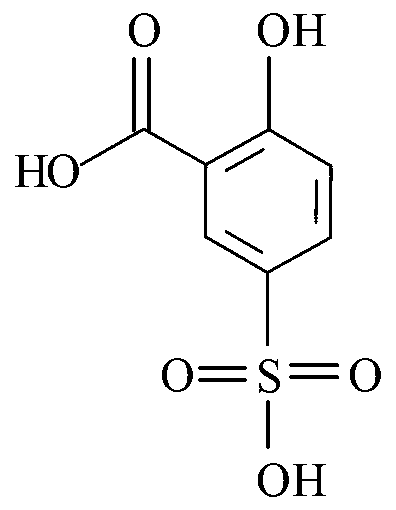

Purification method of 5-sulfosalicylic acid

A sulfosalicylic acid and purification method technology, applied in the field of 5-sulfosalicylic acid purification, can solve the problems of cumbersome operation, high cost, high energy consumption, etc., and achieve safe and convenient purification process and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 350ml of composite purifying agent to 1000g of industrial grade 5-sulfosalicylic acid, heat to 60°C and stir and reflux for 4h, cool to room temperature and then dry and centrifuge to obtain 963g of crude 5-sulfosalicylic acid, the 5-sulfosalicylic acid The crude salicylic acid was dissolved in 500mL of deionized water to make a saturated aqueous solution, then 10g of activated carbon was added and stirred for 3 hours, the activated carbon was removed by filtration, and the filtrate was concentrated under reduced pressure at 70°C to obtain the purified white crystalline product 5-sulfowater Salicylic acid 929g, purity 99.53%;

[0021] The compound cleaning agent used in this embodiment is the mixture of dimethylacetamide, isoamyl acetate, ethyl acetate, butyl acetate, methyl isobutyl ketone and dimethyl phthalate, and its mixing molar ratio is : 0.4:0.3:1:0.7:0.3:0.5.

Embodiment 2

[0023] Add 400ml of composite purifying agent to 1000g of industrial grade 5-sulfosalicylic acid, heat to 65°C and stir and reflux for 5h, cool to room temperature and then drain and centrifuge to obtain 956g of crude 5-sulfosalicylic acid, the 5-sulfosalicylic acid The crude salicylic acid was dissolved in 600mL of deionized water to make a saturated aqueous solution, then 15g of activated carbon was added and stirred for 3.5h, the activated carbon was removed by filtration, and the filtrate was concentrated under reduced pressure at 68°C to obtain the purified white crystalline product 5-sulfo Salicylic acid 917g, purity 99.59%.

[0024] The compound cleaning agent used in this embodiment is the mixture of dimethylacetamide, isoamyl acetate, ethyl acetate, butyl acetate, methyl isobutyl ketone and dimethyl phthalate, and its mixing molar ratio is : 0.3:0.2:1:0.6:0.2:0.4.

Embodiment 3

[0026] Add 450ml of composite purifying agent to 1000g of industrial grade 5-sulfosalicylic acid, heat to 70°C and stir and reflux for 6h, cool to room temperature and then drain and centrifuge to obtain 945g of crude 5-sulfosalicylic acid, the 5-sulfosalicylic acid The crude salicylic acid was dissolved in 700mL of deionized water to make a saturated aqueous solution, then 20g of activated carbon was added and stirred for 4 hours, the activated carbon was removed by filtration, and the filtrate was concentrated under reduced pressure at 65°C to obtain the purified white crystalline product 5-sulfowater Salicylic acid 903g, purity 99.62%.

[0027] The compound cleaning agent used in this embodiment is the mixture of dimethylacetamide, isoamyl acetate, ethyl acetate, butyl acetate, methyl isobutyl ketone and dimethyl phthalate, and its mixing molar ratio is : 0.35:0.25:1:0.65:0.25:0.45.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com