Temperature-sensitive humidity-sensitive functional building material and preparation method thereof

A functional material and construction technology, applied in the field of temperature-sensitive and humidity-sensitive building functional materials and their preparation, can solve the problems of unfavorable circular economy and sustainable development of the ecological environment, inability to effectively control the humidity of the indoor environment, and poor moisture absorption and release performance. Achieve the effect of easy large-scale promotion, excellent temperature control and humidity control effect, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

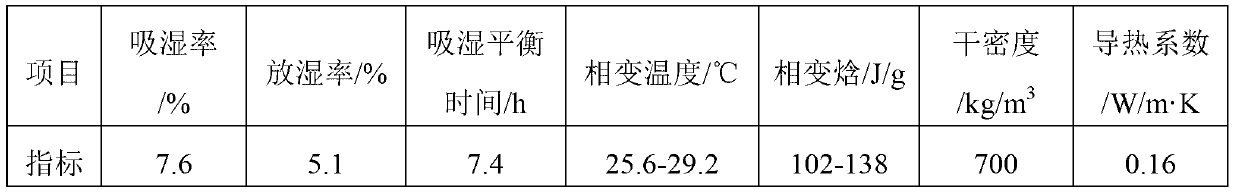

Embodiment 1

[0026] The preparation method of the temperature-sensitive and moisture-sensitive building functional materials provided by the present invention is: ① mix stearic acid, stearyl alcohol, and lauric acid in a glass according to 1:2:4, heat to a molten state, and stir magnetically for 3 hours. After the melt is fully mixed and uniform, it is cooled in a constant temperature water bath to obtain a ternary eutectic. Mix the ternary eutectic and diatomaceous earth at a mass ratio of 1:4, keep it in a molten state for 55 minutes, take it out, grind it, put it in a dryer for use, and obtain a composite temperature control material; The ratio is 1:1 to mix well, in N 2 Under the atmosphere, heat preservation in an electric furnace at 255°C for 3 hours to obtain semi-carbonized plant fibers; ③The phosphogypsum and lime are prepared at a ratio of 12:1 to obtain a cementitious material; ④According to 45 parts of cementitious 8 parts, 20 parts of semi-carbonized plant fiber, 14 parts of ...

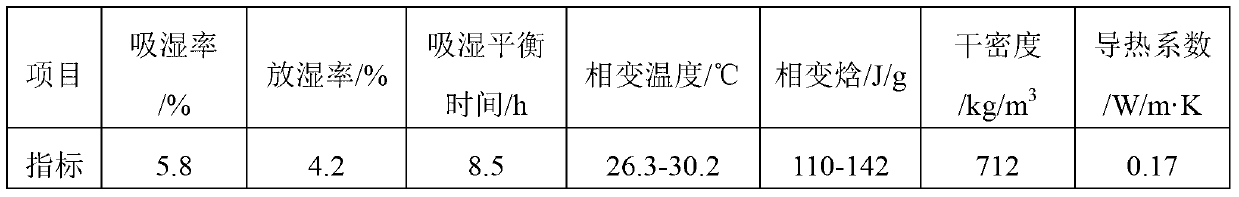

Embodiment 2

[0031] The preparation method of the temperature-sensitive and moisture-sensitive building functional materials provided by the present invention is: ① mix stearic acid, stearyl alcohol, and lauric acid in a glass according to 1:2:1, heat to a molten state, and magnetically stir for 2 hours, After the melt is fully mixed and uniform, it is cooled in a constant temperature water bath to obtain a ternary eutectic. Mix the ternary eutectic and montmorillonite at a mass ratio of 1:5, keep it in a molten state for 60 minutes, take it out, grind it, put it in a dryer for use, and obtain a composite temperature control material; The ratio is 1:4 to mix well, in N 2 Under the atmosphere, heat preservation in an electric furnace at 305°C for 2 hours to obtain semi-carbonized plant fibers and wood chips; ③The desulfurized gypsum and lime were prepared at a ratio of 10:1 to obtain a cementitious material; ④According to 60 parts of cementitious 6 parts of warm material, 30 parts of semi-...

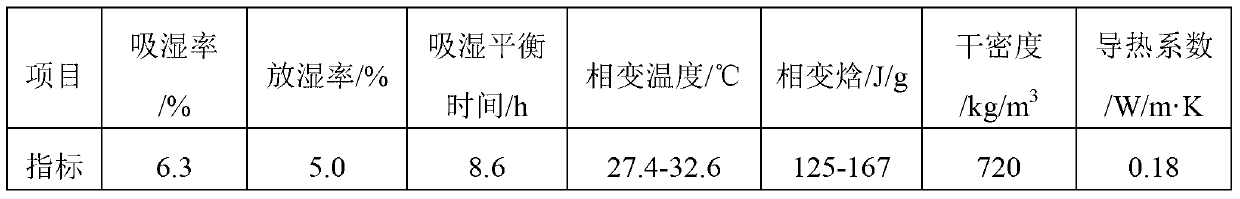

Embodiment 3

[0036] The preparation method of the temperature-sensitive and moisture-sensitive building functional materials provided by the present invention is: ① mix stearic acid, stearyl alcohol, and lauric acid in a glass according to 1:2:4, heat to a molten state, and stir magnetically for 3 hours. After the melt is fully mixed and uniform, it is cooled in a constant temperature water bath to obtain a ternary eutectic. Mix the ternary eutectic and diatomaceous earth at a mass ratio of 1:3, keep it in a molten state for 40 minutes, take it out, grind it, put it in a dryer for use, and obtain a composite temperature control material; The ratio is 1:2 to mix well, in N 2 Under the atmosphere, heat preservation in an electric furnace at 285°C for 2.5 hours to obtain semi-carbonized plant fibers and wood chips; ③Concrete and lime are prepared at a ratio of 15:1 to obtain a cementitious material; ④According to 45 parts of cementitious material, composite temperature control 8 parts of mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com