A medium-low temperature sinterable high-dielectric microwave dielectric ceramic and its preparation method

A microwave dielectric ceramic and low-temperature sintering technology, which is applied in the field of information functional materials, can solve problems such as the decline of quality factor, and achieve the effects of simple preparation process, high practicability and promotion prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

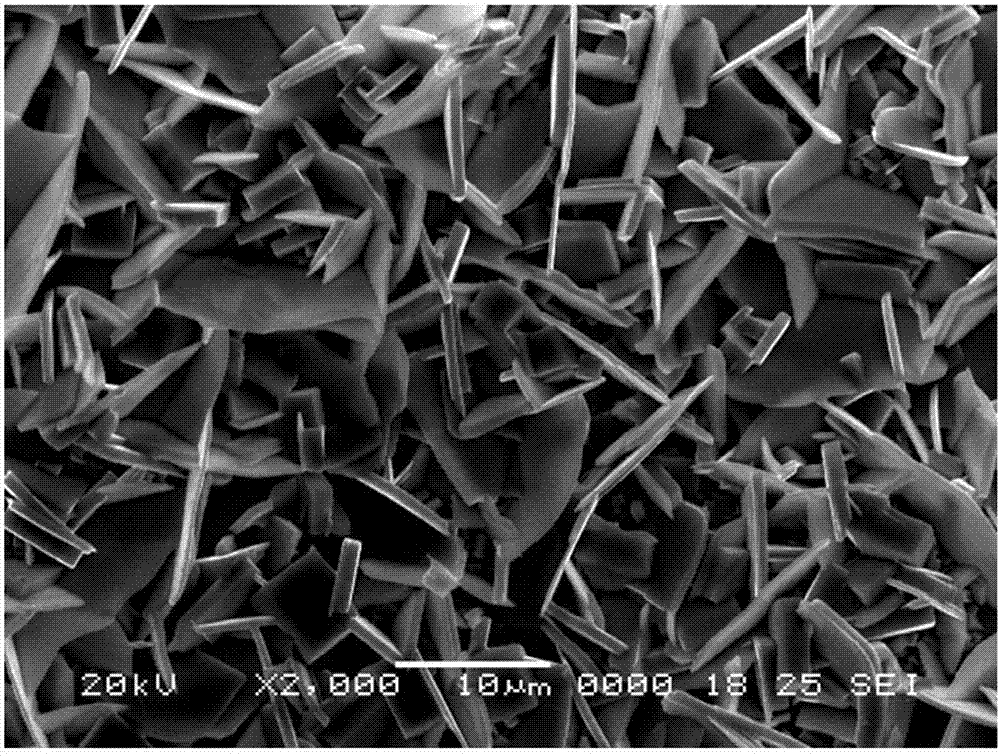

Image

Examples

Embodiment 1

[0017] with CaCO 3 , SrCO 3 , Li 2 CO 3 , Sm 2 O 3 and TiO 2 as raw material, according to the chemical formula (Ca 0.8 Sr 0.2 ) 0.2 (Li 0.5 Sm 0.5 ) 0.8 TiO 3 Carry out proportioning, carry out wet ball milling with absolute ethanol as a medium, and synthesize (Ca after drying at 1100 ° C for 4 hours) 0.8 Sr 0.2 ) 0.2 (Li 0.5 Sm 0.5 ) 0.8 TiO 3 powder; at the same time with Bi 2 O 3 , B 2 O 3 Press Bi as raw material 2 O 3 :B 2 O 3 = 2:1 molar ratio mixing ball milling, drying, and then the resulting Bi 2 O 3 , B 2 O 3 The mixture was incubated at 550 °C for 8 hours to synthesize Bi 4 B 2 O 9 Burning aid.

[0018] put synthetic (Ca 0.8 Sr 0.2 ) 0.2 (Li 0.5 Sm 0.5 ) 0.8 TiO 3 Powder and Bi 4 B 2 O 9 The sintering aid is mixed and ball-milled at a mass percentage of 100:20, and a certain amount of polyvinyl alcohol (PVA) with a mass concentration of 5% is added, mixed evenly, dried, and then pressed into a circular columnar blank on a...

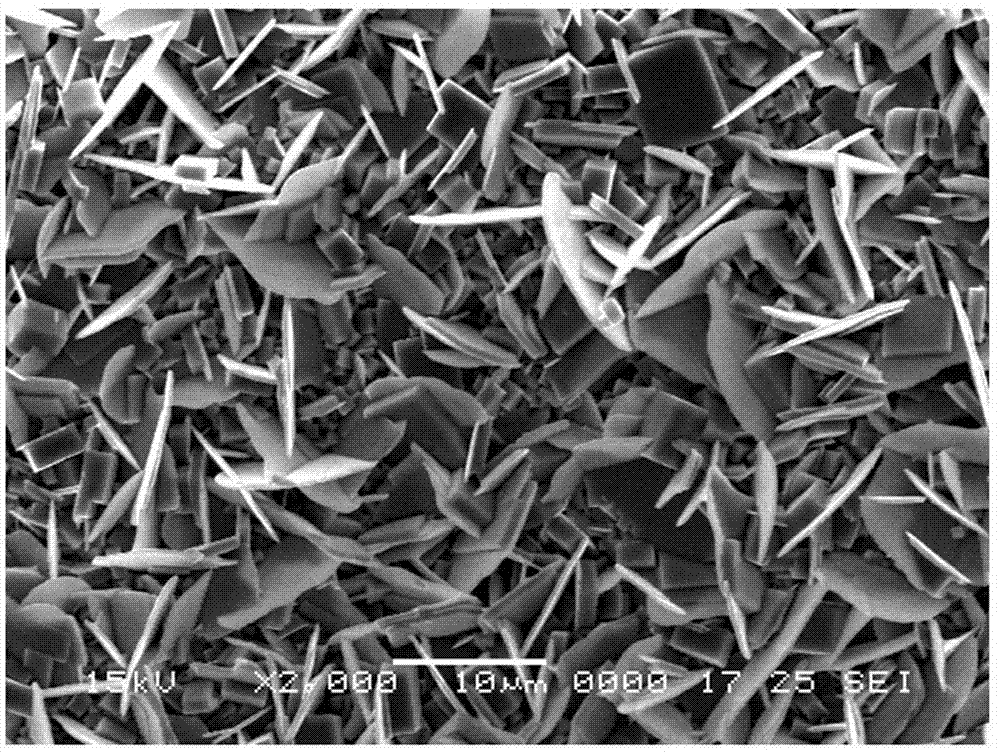

Embodiment 2

[0021] with CaCO 3 , SrCO 3 , Li 2 CO 3 , Sm 2 O 3 and TiO 2 as raw material, according to the chemical formula (Ca 0.8 Sr 0.2 ) 0.3 (Li 0.5 Sm 0.5 ) 0.7 TiO 3 Carry out proportioning, carry out wet ball milling with absolute ethanol as a medium, and synthesize (Ca after drying at 1100 ° C for 4 hours) 0.8 Sr 0.2 ) 0.3 (Li 0.5 Sm 0.5 ) 0.7 TiO 3 powder; at the same time with Bi 2 O 3 , B 2 O 3 Press Bi as raw material 2 O 3 :B 2 O 3 = 2:1 molar ratio mixing ball milling, drying, and then the resulting Bi 2 O 3 , B 2 O 3 The mixture was incubated at 550 °C for 8 hours to synthesize Bi 4 B 2 O 9 Burning aid.

[0022] put synthetic (Ca 0.8 Sr 0.2 ) 0.3 (Li 0.5 Sm 0.5 ) 0.7 TiO 3 Powder and Bi 4 B 2 O 9 The sintering aid is mixed and ball-milled at a mass percentage of 100:25, and a certain amount of polyvinyl alcohol (PVA) with a mass concentration of 5% is added, mixed evenly, dried, and then pressed into a circular columnar body on a ...

Embodiment 3

[0025] with CaCO 3 , SrCO 3 , Li 2 CO 3 , Sm 2 O 3 and TiO 2 as raw material, according to the chemical formula (Ca 0.8 Sr 0.2 ) 0.4 (Li 0.5 Sm 0.5 ) 0.6 TiO 3 Carry out proportioning, carry out wet ball milling with absolute ethanol as a medium, and synthesize (Ca after drying at 1100 ° C for 4 hours) 0.8 Sr 0.2 ) 0.4 (Li 0.5 Sm 0.5 ) 0.6 TiO 3 powder; at the same time with Bi 2 O 3 , B 2 O 3 Press Bi as raw material 2 O 3 :B 2 O 3 = 2:1 molar ratio mixing ball milling, drying, and then the resulting Bi 2 O 3 , B 2 O 3 The mixture was incubated at 550 °C for 8 hours to synthesize Bi 4 B 2 O 9 Burning aid.

[0026] put synthetic (Ca 0.8 Sr 0.2 ) 0.4 (Li 0.5 Sm 0.5 ) 0.6 TiO 3 Powder and Bi 4 B 2 O 9 The sintering aid is mixed and ball-milled at a mass percentage of 100:30, and a certain amount of polyvinyl alcohol (PVA) with a mass concentration of 5% is added, mixed evenly, dried, and then pressed into a circular cylindrical blank o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com