Ardealite-based self-leveling material

A gypsum-based, self-leveling technology, applied in the field of gypsum products, can solve the problem of high production cost and achieve the effects of high utilization rate, simple modification process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

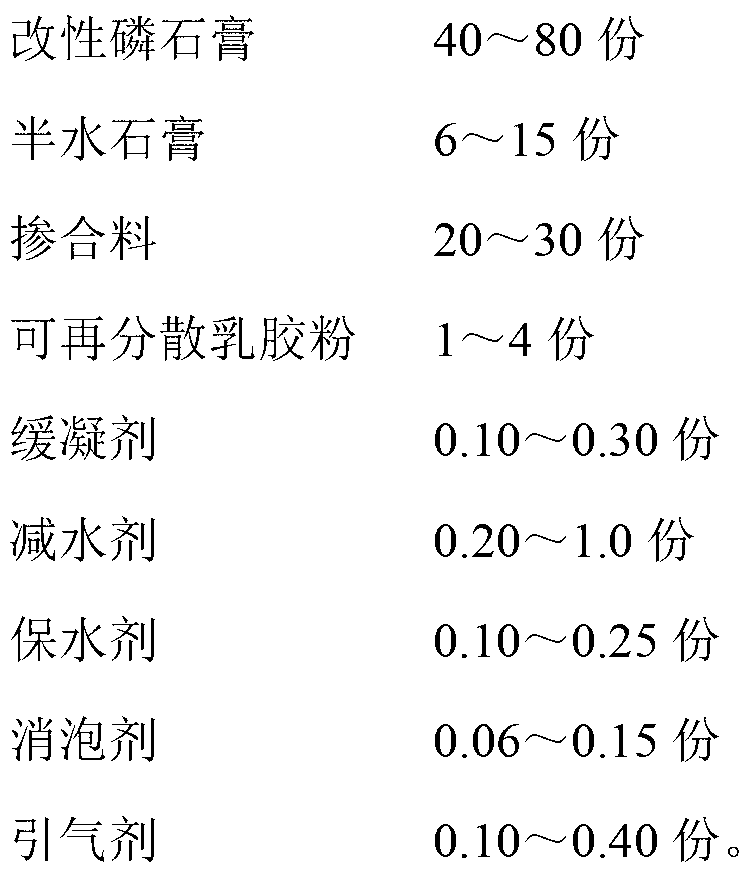

[0020] Embodiment 1: Phosphogypsum-based self-leveling material, the weight ratio of each component is as follows:

[0021] 55 parts of modified phosphogypsum; 15 parts of α hemihydrate gypsum; 28 parts of fly ash, the particle size of fly ash is controlled between 0.08 and 0.12mm; 3 parts of redispersible latex powder, the redispersible latex The powder is a polymer powder made of ethylene and vinyl acetate as monomers; 0.1 part of citric acid; 0.5 part of FDN-C naphthalene-based water reducer; 0.1 part of methyl cellulose; 0.08 part of silicone oil; 0.2 part of rosin resin;

[0022] The modified phosphogypsum is granulated with calcium carbide slag and phosphogypsum after dewatering and sieving in a mass ratio of 1:0.5, stirred evenly, and dried in an anhydrous calcination process at a controlled temperature of 65°C. The drying time is 30 minutes, and the powder becomes a fine powder, which is passed through a sieve of 80-100 mesh.

[0023] Take the above raw materials and ...

Embodiment 2

[0024] Embodiment 2: Phosphogypsum-based self-leveling material, the weight percentage of each component is as follows:

[0025] 70 parts of modified phosphogypsum; 12 parts of α hemihydrate gypsum; 20 parts of fly ash whose particle size is controlled between 0.08 and 0.12 mm; 2 parts of redispersible latex powder; The powder is a polymer powder made of ethylene and vinyl acetate as monomers; 0.1 part of citric acid; 0.5 part of FDN-C naphthalene-based water reducer; 0.15 part of methyl cellulose; 0.08 part of silicone oil; share;

[0026] The modified phosphogypsum is granulated with calcium carbide slag and phosphogypsum after dewatering and sieving in a mass ratio of 1:0.8, stirred evenly, and dried in an anhydrous calcination process at a controlled temperature of 70°C. The drying time is 30 minutes, and the powder becomes a fine powder, which is passed through a sieve of 80-100 mesh.

[0027] Take the above raw materials and mix them to obtain a phosphogypsum-based sel...

Embodiment 3

[0028] Embodiment 3: Phosphogypsum-based self-leveling material, the weight percentage of each component is as follows:

[0029] 50 parts of modified phosphogypsum, 15 parts of α hemihydrate gypsum, 30 parts of fly ash, the particle size of fly ash is controlled between 0.08 and 0.12mm; 3 parts of redispersible latex powder, the redispersible latex The powder is a polymer powder made of ethylene and vinyl acetate as monomers; 0.15 parts of citric acid, 0.3 parts of PC-1016 polycarboxylate superplasticizer, 0.15 parts of methyl cellulose, high-carbon fatty alcohol polyoxyethylene ether nonionic 0.1 part of surfactant, 0.1 part of sodium dodecylbenzenesulfonate,

[0030] Among them: modified phosphogypsum is granulated with calcium carbide slag after crushing and phosphogypsum at a ratio of 1:0.3, stirred evenly, and dried in an anhydrous calcination process. The controlled temperature is 60°C, and the drying time is 25 minutes. For fine powder, pass it through a sieve of 80-10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com