Method for dynamically monitoring torque of main milling head of numerical-control floor type boring and milling machine

A dynamic monitoring, milling and boring machine technology, applied in metal processing mechanical parts, measuring/indicating equipment, metal processing equipment, etc., can solve the damage accuracy of the main milling head and the attachment milling head, can not truly reflect the maximum torque value, ignore the rated torque Limits and other issues to avoid damage or precision damage, easy to operate and master, and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

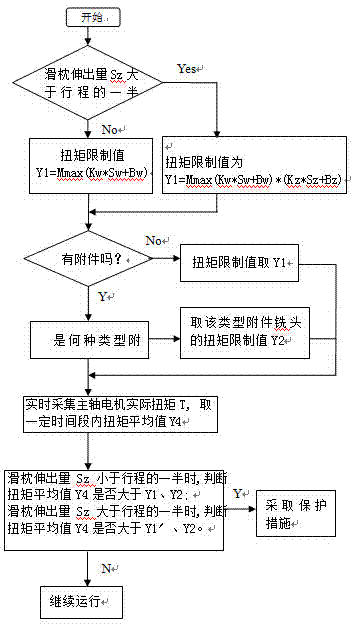

[0024] The dynamic monitoring method of the torque of the main milling head of the CNC floor-type milling and boring machine of the present invention is to calculate the torque attenuation caused by the extension of the boring bar and the ram, and at the same time use the numerical control function to collect the actual torque of the main milling head in real time, and within the set time The actual torque of the main milling head is compared with the calculated allowable torque in real time, and dynamically monitored to limit the torque of the main milling head within the allowable range.

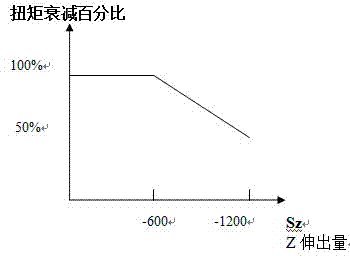

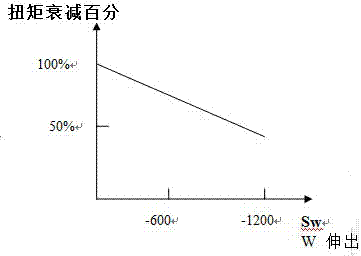

[0025] Such as image 3 As shown, the embodiment is now described: firstly, the characteristic curve t1 between the displacement of the boring bar in the W-axis direction and the torque attenuation percentage of the main milling head and the displacement of the ram in the Z-axis direction and the torque attenuation of the main milling head are respectively established. Characteristic curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com