Automobile hub bore numerical control milling device

An automotive wheel hub, CNC milling technology, applied in feeding devices, metal processing, metal processing equipment and other directions, can solve the problems of expensive equipment and complex structure, and achieve the effect of facilitating rapid movement, improving machine tool accuracy, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

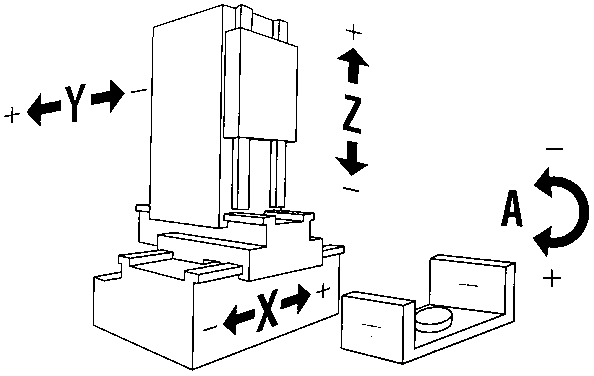

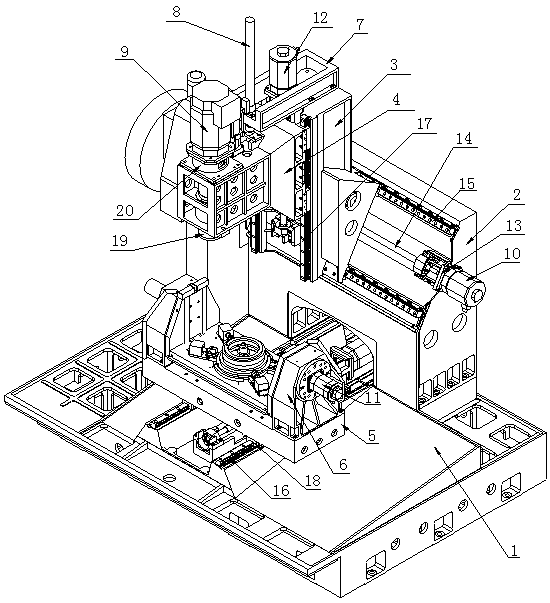

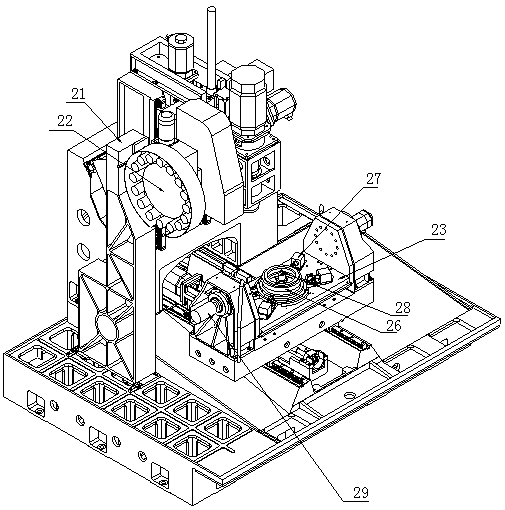

[0030] Such as figure 2 , image 3 As shown, the automobile hub hole coefficient controlled milling processing device of the present invention includes a base 1, a column 2, a tool magazine 22, a spindle motor 9, a spindle 19, and a spindle box 4. The column 2 is installed on the base 1, and the tool magazine 22 passes through the tool The library bracket 21 is installed on the base 1, and the main shaft 19 is connected with the main shaft motor 9.

[0031] A Y-axis screw 14 is installed on the base 1 in the front-to-rear direction, and the Y-axis screw 14 is connected to the Y-axis motor 10; the base 1 is also provided with a Y-axis sliding table 5, and the bottom of the Y-axis sliding table 5 has a nut seat, The nut seat is assembled with the Y-axis screw, the mating surface of the base 1 and the Y-axis sliding table is also assembled through the Y-axis guide 16 and the Y-axis slider 18, the Y-axis guide 16 and the Y-axis slider 18 are assembled with The Y-axis screw is arrang...

Embodiment 2

[0042] The workflow of the present invention:

[0043] Properly adjust the position of the hydraulic clamp 27 to make it possible to process the appropriate wheel shape, and place the aluminum alloy wheel hub on the center expansion sleeve 26 for preliminary positioning. Press the system operation panel to start the switch and the automatic door closes. The four hydraulic devices on the hydraulic clamp 27 compress the edge of the hub (pressure: 4Mpa), and then the clamp center expands and tightens, and finally the hub is positioned. X, Y, Z three-axis linkage for rapid positioning, the cutting fluid is opened to process bolt holes, flange holes, decorative holes, etc. The fourth axis A axis is turned over at an appropriate angle to process valve holes, chamfers and shaved edges. (Realize one clamping in place) After the process is completed, each axis returns to the reference point, the hydraulic devices 271 of the four hydraulic clamps are released, the center expansion sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com