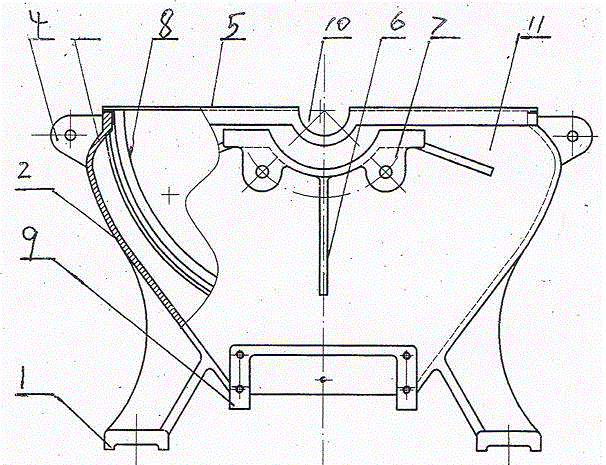

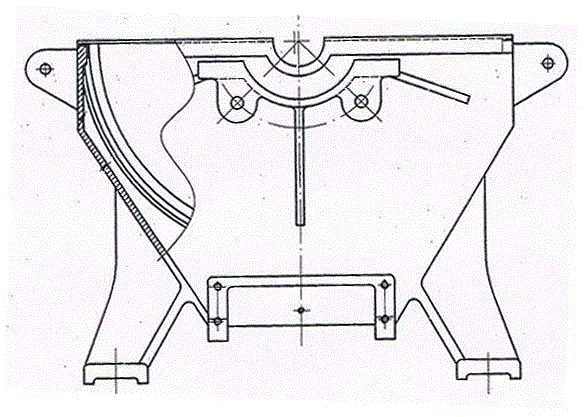

Feed grinder base

A pulverizer and machine base technology, which is applied in grain processing, etc., can solve the problems of affecting the appearance of the machine, the large size of the crushed particles, and the poor flow of materials, etc., and achieve the effect of simple structure, uniform thickness and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1, The seat plate (8) is in the shape of a flat tripod, the front and back of the seat plate (8) are flat surface panels (11), the two sides of the panel (11) are side bottom shells (2) of arc surface, the top surface (5), the upper and lower The connection seat (7) is connected with the upper machine base, and is connected with bolts through the upper and lower connection seats (7) at the same time, with ears (4) on both sides, and a bottom flange (9) at the bottom of the seat plate. There are feet (1) at the bottom of the seat plate (8). The shell of the seat plate (8) is an arc-shaped side bottom shell (2), which is connected with the bent section as a transition arc. The bending section is also arc-shaped. The junction between the top edge and the top surface (5) is also a transition arc transition, and the transition arc angle is 55 degrees.

Embodiment 2

[0015] Example 2, Referring to the structural configuration of Example 1. The side bottom shell (2) does not need to be connected with the bent section, but directly connects with the top surface (5) to form an arc, so that the bottom of the side bottom shell (2) is straight to the seat edge of the seat plate (8). It has no transition corners.

Embodiment 3

[0016] Example 3, Referring to the structural configuration of Example 1. The bending section is connected with the side bottom shell (2) by a transition arc, and the arc angle is 45 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com