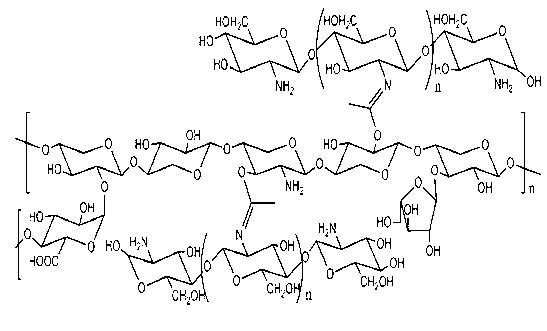

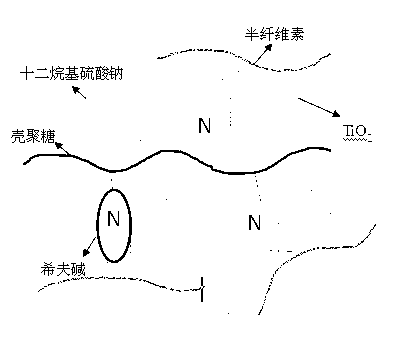

Preparation method and application of hemicellulose/chitosan/nano TiO2 hybrid material

A technology of hemicellulose and hybrid materials, applied in the fields of material science and environmental science, can solve problems such as unfavorable recycling, lower adsorption performance, and limited application range, etc., to reduce the gradual depletion of raw materials, significant adsorption effect, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 0.01g modified nano-TiO 2 Disperse in 50mL of 2% (v / v) dilute acetic acid solution, stir magnetically for 1h, add 1.5g chitosan, stir magnetically for 7h, ultrasonically disperse the solution for 15min every half hour, and dissolve completely after stirring for 12h to obtain chitosan / Nano-TiO 2 Emulsion; then in chitosan / nano-TiO 2 Add 6g of hemicellulose xylan to the emulsion, stir magnetically for 1-2 hours, and dissolve completely to obtain hemicellulose / chitosan / nano-TiO 2 Emulsion; the prepared hemicellulose / chitosan / nano-TiO 2 The emulsion was refluxed in an oil bath at 100°C for 30-60 minutes to obtain a light brown gel. The gel was further thermally cross-linked at 40°C for 6-9 hours, and then freeze-dried for 24 hours to obtain hemicellulose / chitosan / nano-TiO 2 hybrid materials.

Embodiment 2

[0024] 0.02g modified nano-TiO 2 Disperse in 50mL of 2% (v / v) dilute acetic acid solution, stir magnetically for 1h, add 1.5g chitosan, stir magnetically for 7h, ultrasonically disperse the solution for 15min every half hour, and dissolve completely after stirring for 12h to obtain chitosan / Nano-TiO 2 Emulsion; then in chitosan / nano-TiO 2 Add 6g of hemicellulose xylan to the emulsion, stir magnetically for 1-2 hours, and dissolve completely to obtain hemicellulose / chitosan / nano-TiO 2 Emulsion; the prepared hemicellulose / chitosan / nano-TiO 2 The emulsion was refluxed in an oil bath at 100°C for 30-60 minutes to obtain a light brown gel. The gel was further thermally cross-linked at 40°C for 6-9 hours, and then freeze-dried for 24 hours to obtain hemicellulose / chitosan / nano-TiO 2 hybrid materials.

Embodiment 3

[0026] 0.03g modified nano-TiO 2 Disperse in 50mL of 2% (v / v) dilute acetic acid solution, stir magnetically for 1h, add 1.5g chitosan, stir magnetically for 7h, ultrasonically disperse the solution for 15min every half hour, and dissolve completely after stirring for 12h to obtain chitosan / Nano-TiO 2 Emulsion; then in chitosan / nano-TiO 2 Add 6g of hemicellulose xylan to the emulsion, stir magnetically for 1-2 hours, and dissolve completely to obtain hemicellulose / chitosan / nano-TiO 2 Emulsion; the prepared hemicellulose / chitosan / nano-TiO 2 The emulsion was refluxed in an oil bath at 100°C for 30-60 minutes to obtain a light brown gel. The gel was further thermally cross-linked at 40°C for 6-9 hours, and then freeze-dried for 24 hours to obtain hemicellulose / chitosan / nano-TiO 2 hybrid materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com