Shield conductor

A technology for shielding conductors and shielding parts is applied in the field of shielding conductors, which can solve the problems of ineffective use of space to arrange shielded conductors, and achieve the effect of effective arrangement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

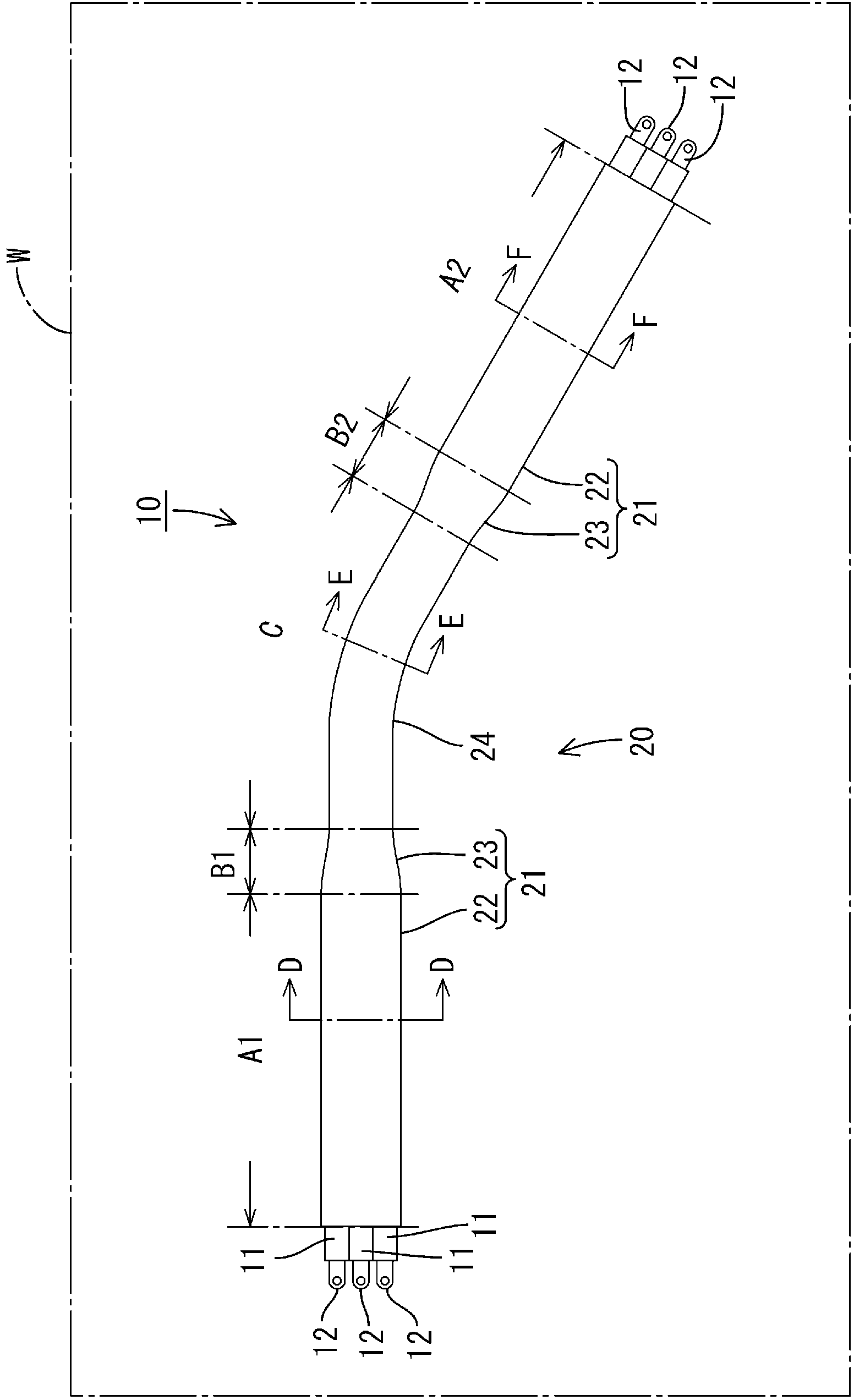

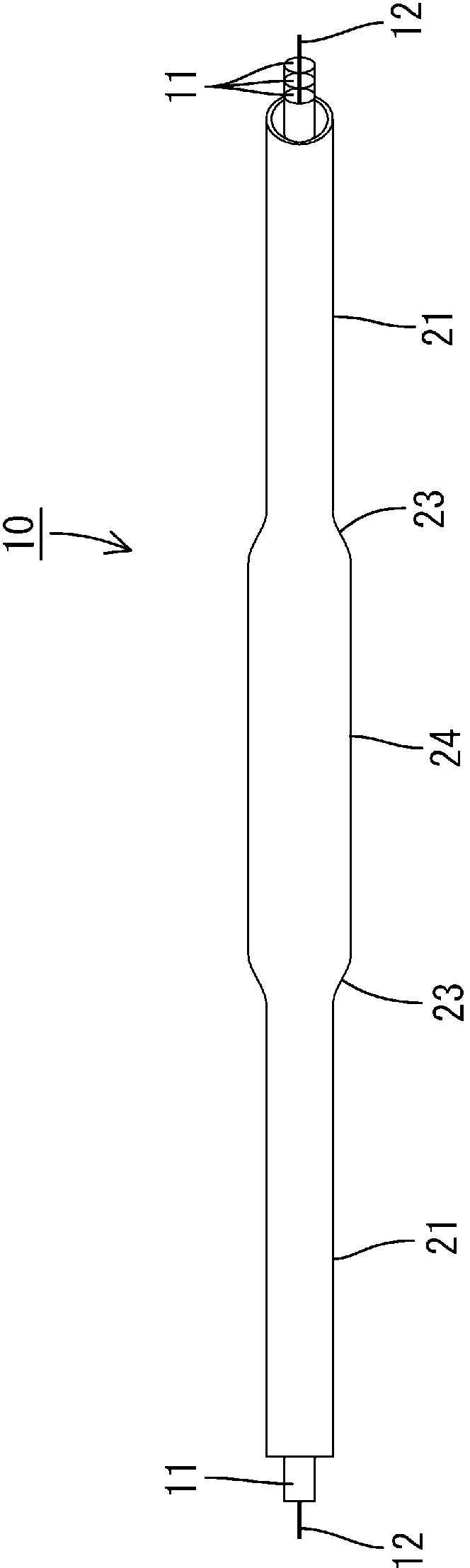

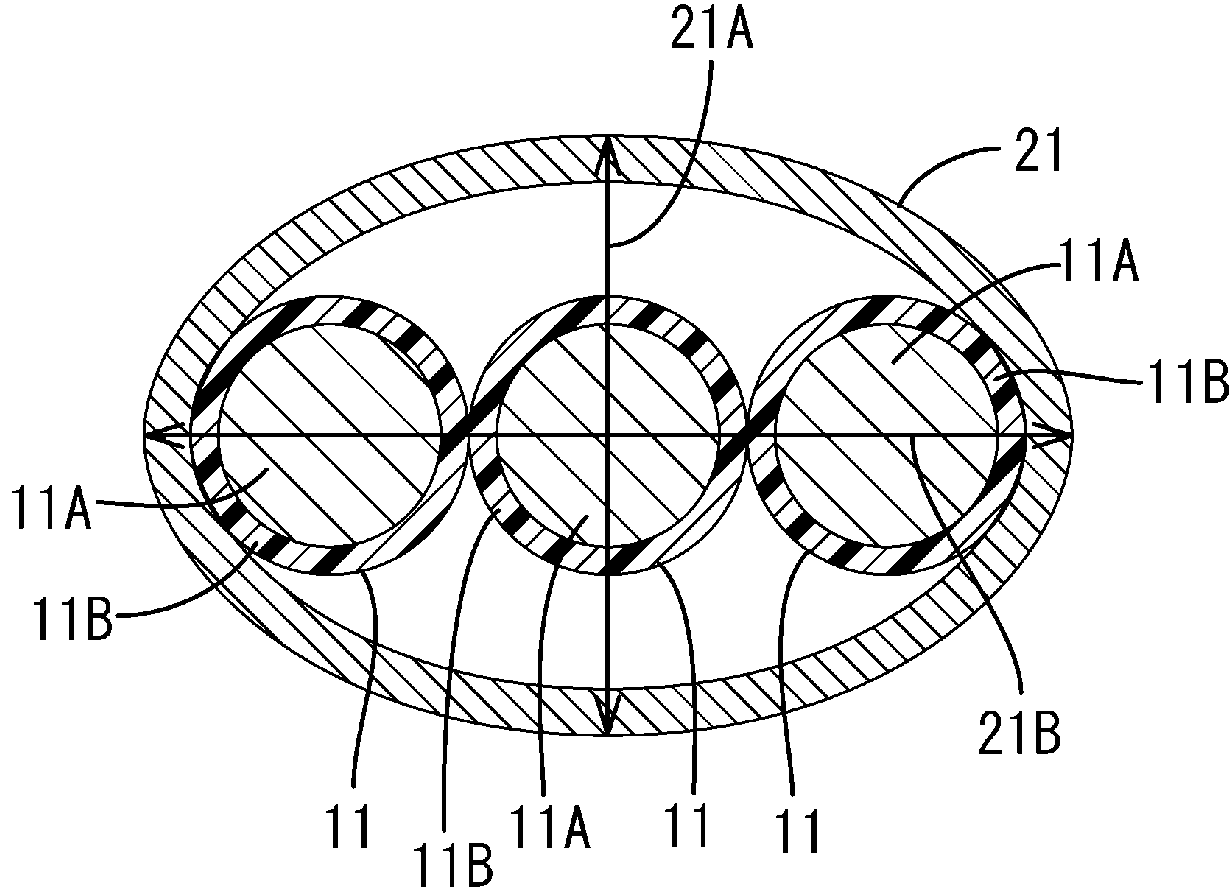

[0049] refer to Figure 1 to Figure 7 A first embodiment of the present invention is described. The shield conductor 10 of this embodiment is routed between devices in a power source including a battery, an inverter, and a motor (not shown) for driving an electric vehicle. The shield conductor 10 arranged between the battery and the inverter includes two electric wires 11 . The shield conductor 10 arranged between the inverter and the motor includes three electric wires 11 . In the following description, the shielded conductor 10 which includes three electric wires 11 and which is arranged (or wired) under the floor of the vehicle W between the inverter and the motor will be described. In this manual, figure 1 The left and right lower sides in are defined as the front and rear sides, respectively. compared to figure 2 And limit the top-bottom direction.

[0050] Such as figure 1 As shown, the shielded conductor 10 includes three wires 11 and a tube 20 . The wire 11 pa...

no. 2 example

[0082] will refer to Figure 8 with Figure 9 A second embodiment of the present invention is described. The same components as those in the above-described embodiment will be denoted by the same reference numerals and will not be explained.

[0083] In the second embodiment, the outer circumference of the shielded conductor 10 is covered by a heat shrinkable tube 40, such as Figure 8 shown. Such as Figure 9 As shown, the shielded conductor 10 is inserted into the heat shrinkable tube 40, and then the heat shrinkable tube 40 is heated to shrink it. As a result, the heat-shrinkable tube 40 is tightly attached to the outer peripheral surface of the tube 20 .

[0084] Since the heat-shrinkable tube 40 is tightly adhered to the outer circumference of the tube 20 , the outer circumference of the tube 20 is protected by the heat-shrinkable tube 40 .

no. 3 example

[0086] will refer to Figure 10 A third embodiment of the present invention is described. The same components as those in the above-described embodiment will be denoted by the same reference numerals and will not be explained. The tube 20 according to the above-described embodiment is made of a material such as aluminum alloy. In a third embodiment, the tube 50 is made of a cladding material comprising a first element 51 on the inner side and a second element 52 on the outer side, as Figure 10 Hierarchical settings are shown.

[0087] The first member 51 is made of aluminum or an aluminum alloy. The second element 52 is made of iron or an iron alloy.

[0088] The braided wire 53 includes a tinned copper alloy wire. At the end of the tube 50 , a braided wire 53 covers the outer circumference of the second element 52 . At the end of the tube 50 (on the end of the second member 52 of the tube 50 ) the tube 50 and the braided wire 53 are connected by means of connection suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com