LiSiPON (lithium silicon phosphorus) lithium-ion battery solid electrolyte film, and preparation method and application thereof

A solid-state electrolyte and lithium-ion battery technology, applied in secondary batteries, ion implantation plating, circuits, etc., can solve the problems that limit the improvement and improvement of all-solid-state thin-film lithium batteries, low electronic conductivity, and backward research on electrolyte thin films. Achieve excellent stability, great social benefits, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Adjust Ar, N 2 Flow ratio of synthesized LiSiPON electrolyte film:

[0043] (1) Before the experiment, the Si wafers were ultrasonically cleaned with acetone and absolute alcohol for 15 min, dried and put into the coating chamber.

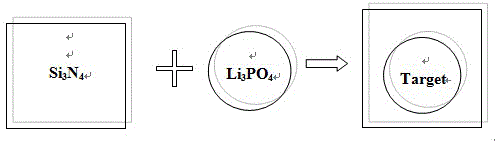

[0044] (2) Put the circular Li 3 PO 4 The target is fixed on the square Si 3 N 4 On the target, put it on the target platform A in the vacuum chamber, and evacuate the chamber so that the background vacuum degree in the chamber is 2.8×10 -4 Pa.

[0045] (3) Use a mass flow meter to control the Ar intake flow rate to keep it at about 20 sccm, turn on the ion gun power supply, sputtering energy 500eV, sputtering beam current 20mA, and accelerating current 5mA. Wash the samples by bombardment for at least 5 min. Power off the ion gun.

[0046] (4) Turn on the sputtering ion source, control the Ar intake flow rate with a mass flow meter to keep it at about 2 sccm, and turn on the N 2 The intake valve controls the flow rate of 2sccm, 1s...

Embodiment 2

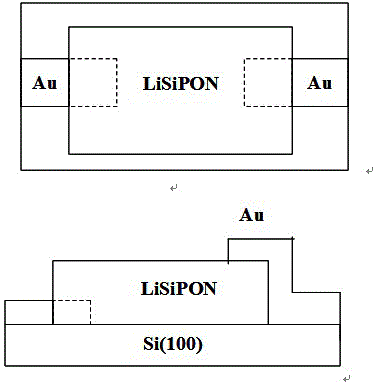

[0053] For the purpose of measuring the ionic conductivity of the thin film electrolyte, Au, LiSiPON film and Au were sequentially deposited on a Si(100) substrate to form an Au / LiSiPON / Au "sandwich" structure (such as figure 2 ). The specific implementation steps are as follows:

[0054] (1) Before the experiment, the sputtering target was adjusted to the Au target, and the Si wafer was ultrasonically cleaned with acetone and absolute alcohol for 15 min, dried and put into the coating chamber.

[0055] (2) Vacuum the chamber so that the background vacuum in the chamber is 2.8×10 -4 Pa.

[0056] (3) Use a mass flow meter to control the Ar intake flow rate to keep it at about 20 sccm, turn on the ion gun power supply, sputtering energy 500eV, sputtering beam current 20mA, and accelerating current 5mA. Wash the samples by bombardment for at least 5 min. Power off the ion gun.

[0057] (4) Turn on the sputtering ion source, and use a mass flow meter to control the Ar intak...

Embodiment 3

[0066] Application of LiSiPON as Electrolyte Film in All-Solid Thin Film Lithium Batteries

[0067] All-solid-state thin-film battery LiCoO 2 Preparation of / LiSiPON / Li

[0068] (1) LiCoO was plated on the Si(110) substrate by RF magnetron sputtering before the experiment 2 Thin film electrode, sputtering time is 4h.

[0069] (2) Use ion beam-assisted deposition equipment to plate thin-film electrolytes, and adjust the sputtering target position to Li 3 PO 4 and Si 3 N 4 Composite target (as described in Example 1), vacuumize the chamber so that the background vacuum in the chamber is 2.8×10 -4 Pa.

[0070] (3) Turn on the sputtering ion source, adjust the Ar flow rate to 2 sccm, N 2 The flow rate is 2 sccm, the sputtering energy is 1.1 keV, and the sputtering beam current is 20 mA. The accelerating voltage is 200V, and the accelerating current is 4mA. Sputtering time is 5h.

[0071] (4) The film is in the high vacuum chamber, and the chamber is not opened until th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com