A wood frame shear wall

A wood frame and wood frame column technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of wall panel wall structure loss bearing capacity, normal use and living troubles, panel nails shearing, pulling out, etc. Ductility and energy dissipation capacity, meet fire safety requirements, good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

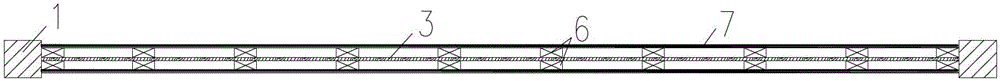

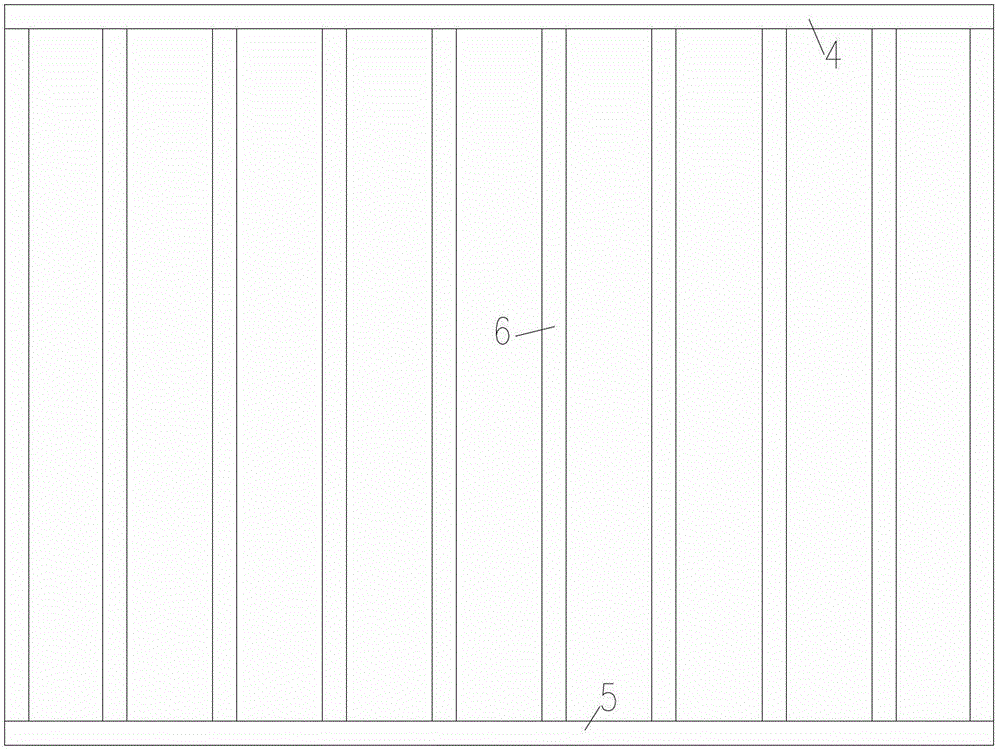

[0025] Such as Figure 1-6 Shown: a wood frame shear wall, including wood frame columns 1, wood frame beams 2, wood base structural panels 3, top beam panels 4, bottom beam panels 5, wall stud columns 6 and gypsum boards 7, the The wood-based structural board 3 is arranged in the middle of the wall, and the stud columns 6 are multiple, respectively arranged between the top beam 4 and the bottom beam 5 to form a wall stud frame, and the wall stud frame is symmetrically arranged on the wood-based structural board 3, the gypsum board 7 is arranged on the outside of the stud frame, and the edges are flush with the outside of the stud frame.

[0026] The distance between the stud columns 6 is 400-600mm. The stud frame and the wood-based structural board 3 are fixedly connected by nails, the length of the nails is 70-90 mm, and the distance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com