Preprocessing method capable of effectively improving efficiency of generating fermentable sugar by bamboo cellulose enzyme hydrolysis

A cellulase, pretreatment technology, used in fermentation and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Select 2 to 3-year-old bamboo, use a chipper to obtain bamboo chips with a three-dimensional size of 30×15×5mm, and use them as raw materials;

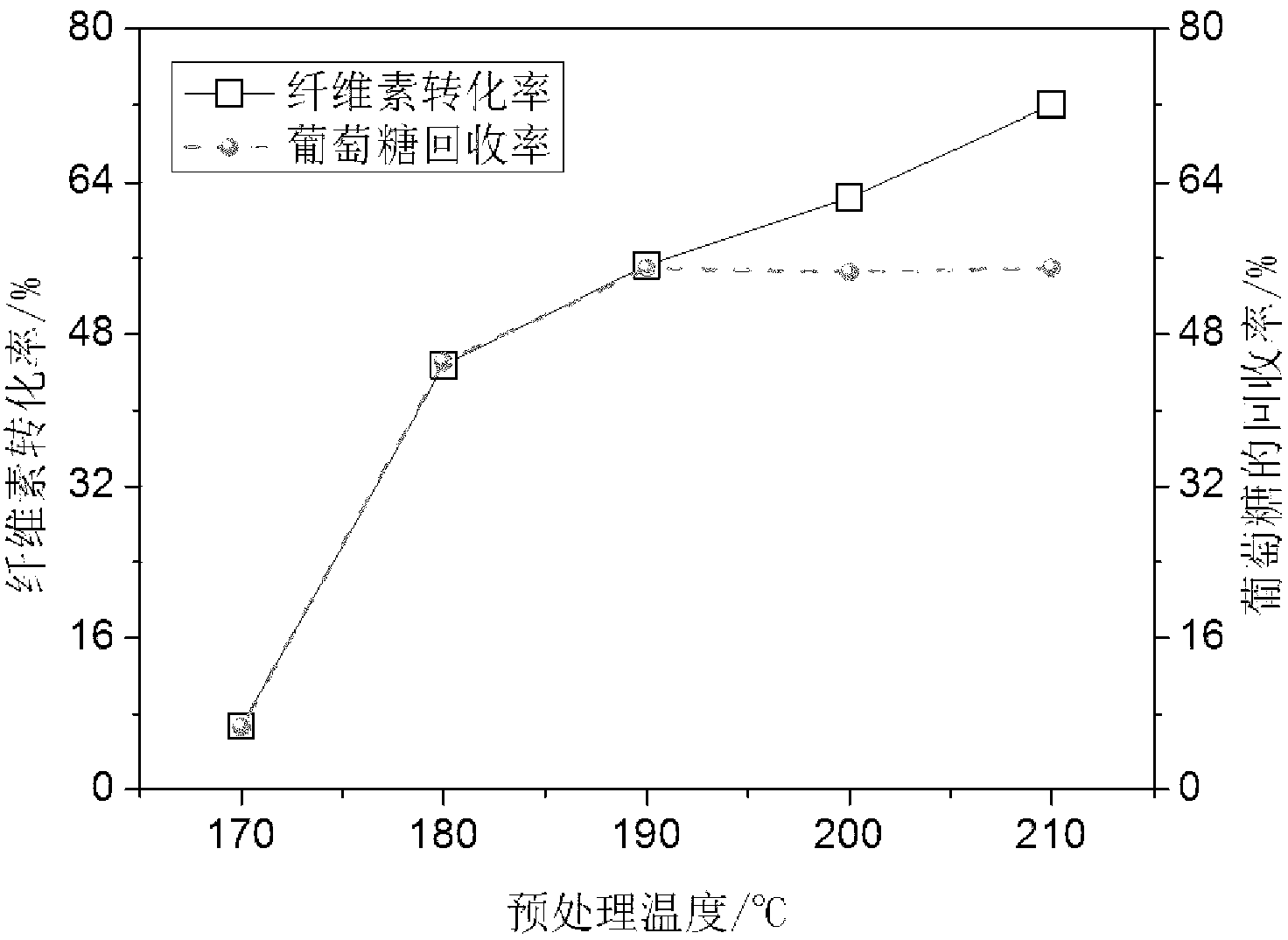

[0051] (2) High-boiling alcohol pretreatment, the technical conditions are: liquid-solid ratio of 6 (ratio of high-boiling alcohol pretreatment liquid volume to bamboo chip raw material mass, ml:g), high-boiling alcohol 1,4-butanediol The volume ratio in the pretreatment liquid (composed of alcohol and water) is 10% (% refers to volume percentage, ml: ml), and 180°C is selected in the pretreatment temperature range of 170~210°C for the experiment. The experimental results are shown in Table 1 As shown, the pretreatment time is 25min, and the concentration value of sulfuric acid in the pretreatment liquid as a catalyst is shown in Table 1. After the pretreatment is completed, the small tank in the oil bath reactor is immediately taken out, cooled with tap water, and then placed on a double-layer Filter on a Buchner funnel of...

Embodiment 2

[0057] (1) Select 2 to 3-year-old bamboo, use a chipper to obtain bamboo chips with a three-dimensional size of 30×15×5mm, and use them as raw materials;

[0058] (2) High-boiling alcohol pretreatment, the technical conditions are: the liquid-solid ratio is 6 (the ratio of high-boiling alcohol pretreatment liquid volume and bamboo chip raw material quality, ml: g), and the high-boiling alcohol 1,4 - The volume ratio of butanediol in the pretreatment solution (composed of alcohol and water) is 0~100% (% refers to the volume percentage, ml: ml) and select 0%, 10%, 20%, 35%, 40% in the range , 50%, 65%, 80% and 100% for experiments, see the experimental results figure 1 As shown, the pretreatment temperature is 190 ° C, and the pretreatment time is 45 minutes. After the pretreatment is completed, the small tank in the oil bath reactor is immediately taken out, cooled with tap water, and then filtered on a Buchner funnel with double-layer filter paper. solid and liquid separation...

Embodiment 3

[0063] (1) Select 2 to 3-year-old bamboo, use a chipper to obtain bamboo chips with a three-dimensional size of 30×15×5mm, and use them as raw materials;

[0064] (2) High-boiling alcohol pretreatment, the technical conditions are: liquid-solid ratio of 6 (ratio of high-boiling alcohol pretreatment liquid volume to bamboo chip raw material mass, ml:g), high-boiling alcohol 1,4-butanediol The volume ratio in the pretreatment solution (composed of alcohol and water) is 40% (% refers to the volume percentage, ml: ml), and the pretreatment temperature range is 170~210°C, and 190°C is selected for the experiment, and the pretreatment time is 45min. After the treatment is completed, the small tank in the oil bath reactor is immediately taken out, cooled with tap water, and then filtered on a Buchner funnel with a double layer of filter paper to separate the solid from the liquid;

[0065] (3) Dilute sulfuric acid, dilute alkali, acid sulfite and ethanol / water pretreatment, the techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com