Alcohol ether biodiesel and mixed diesel containing alcohol ether biodiesel

A technology of biodiesel and alcohol ether, which is applied in the field of clean energy, can solve the problems of high viscosity of biodiesel, poor promotion of biodiesel, and poor combustion completeness, etc., and achieve the effects of strong fluidity, expanding the scope of use, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: No. A alcohol ether biodiesel

[0018] Get the coconut oil alcohol of 9200Kg as the base fluid of preparing alcohol ether biodiesel of the present invention. Add 15Kg of isoamyl nitrate in the base liquid as a cetane number improver, so that the cetane number of the prepared alcohol ether biodiesel is between 45-60. In this way, it can not only avoid the knocking of the diesel engine caused by the combustion delay of the obtained alcohol ether biodiesel, but also prevent the obtained alcohol ether biodiesel from emitting black smoke and polluting the environment due to incomplete combustion. Add 500Kg of di-n-amyl ether into the base liquid, so that the alcohol ether biodiesel can be fully burned, and then improve the utilization rate of the alcohol ether biodiesel. Add the surfactant of 150Kg in base liquid, this surfactant comprises the alkanolamide of 2.5Kg, the isopropanolamine of 1.5Kg and 146Kg by alkylamine salt, purity is 50% alkanolamide and etha...

Embodiment 2

[0022] Embodiment 2: No. B alcohol ether biodiesel

[0023] Get the mixed liquid of coconut oil and octanol as base fluid, wherein, coconut oil 7000Kg, octanol 1500K. Add 100Kg of cetane number improver to the base liquid, preferably diisoamyl oxalate; 600Kg of linear ether, preferably di-n-pentyl ether, or ethylene glycol methyl ether and / or butyl ether; 200Kg Surfactant, wherein, alkanolamide 50Kg, the compound 150Kg that is formed by mixing alkanolamide and ethanolamine by alkylamine salt, purity 50% by weight ratio of 1:1:1; 40Kg pour point depressant , wherein, 25Kg of styrene ester polymer, 15Kg of methacrylate polymer; 160Kg of co-solvent, preferably isobutanol; 400Kg denatured methanol, the denatured methanol is formed by mixing methanol and hexaphosphine amine, preferably, methanol and hexaphosphine The weight ratio of phosphine to amine is 2000:1. Mix the obtained base liquid with cetane number improver, linear ether, surfactant, pour point depressant, cosolvent an...

Embodiment 3

[0029] Embodiment 3: No. C alcohol ether biodiesel

[0030] Get the coconut oil alcohol of 6800Kg as base liquid, and in this base liquid, add the diisoamyl oxalate of 150Kg, the di-n-pentyl ether of 800Kg and the denatured methyl alcohol of 1500Kg; The tensio-active agent of 300Kg, wherein, alkanolamide 50Kg , 250Kg of compound formed by mixing alkylamine salt, alkanolamide and ethanolamine with a purity of 50% in a weight ratio of 1:1:1; 100Kg of pour point depressant, wherein, styrene ester polymer and ethylene- Acrylic acid vinyl ester copolymer 50Kg respectively; The auxiliary solvent of 350Kg, preferably n-butanol. The mixed solution formed by mixing the coconut oil alcohol, diisopentyl oxalate, di-n-pentyl ether, denatured methanol, surfactant, pour point depressant and cosolvent can be evenly mixed to obtain No. C alcohol ether biodiesel.

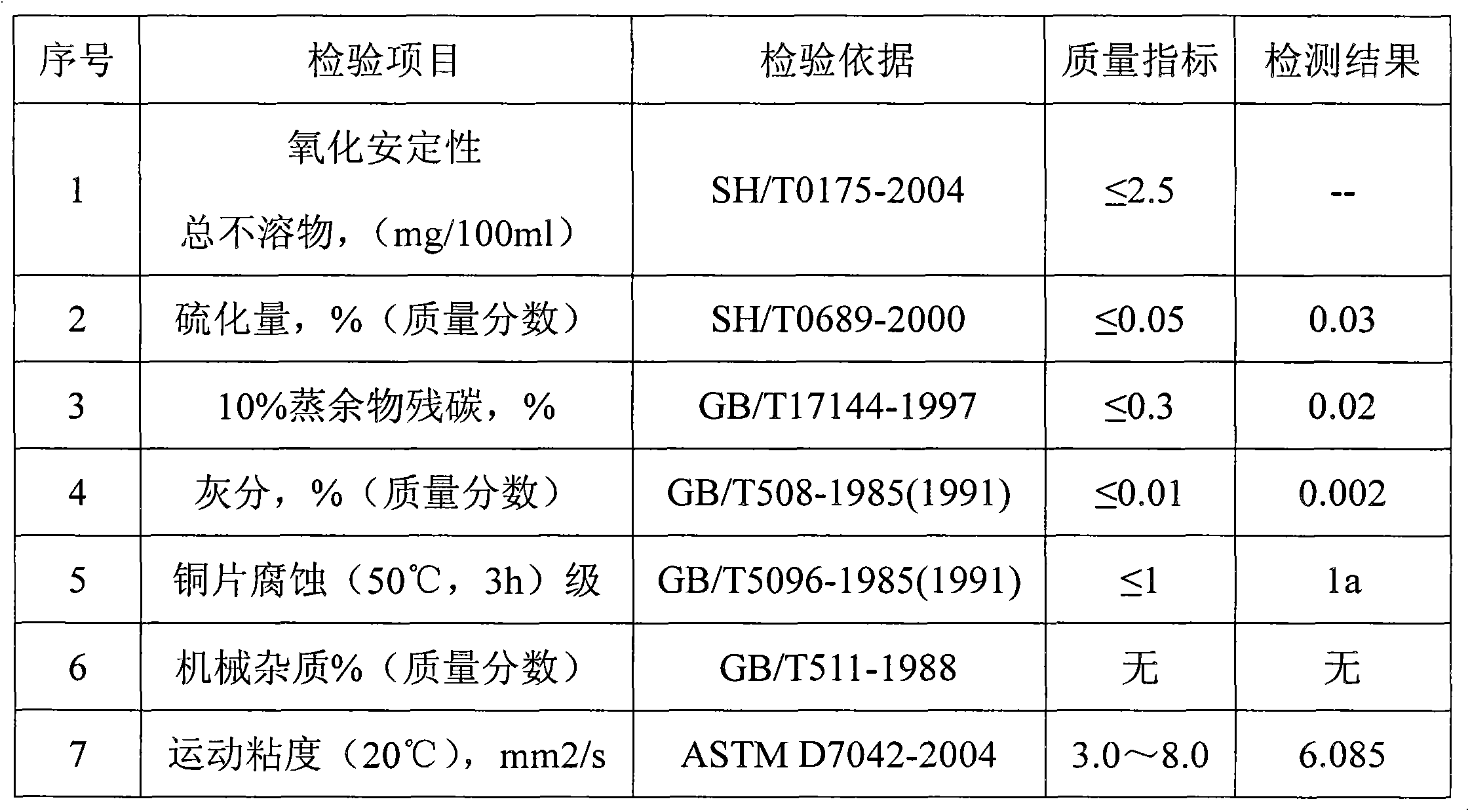

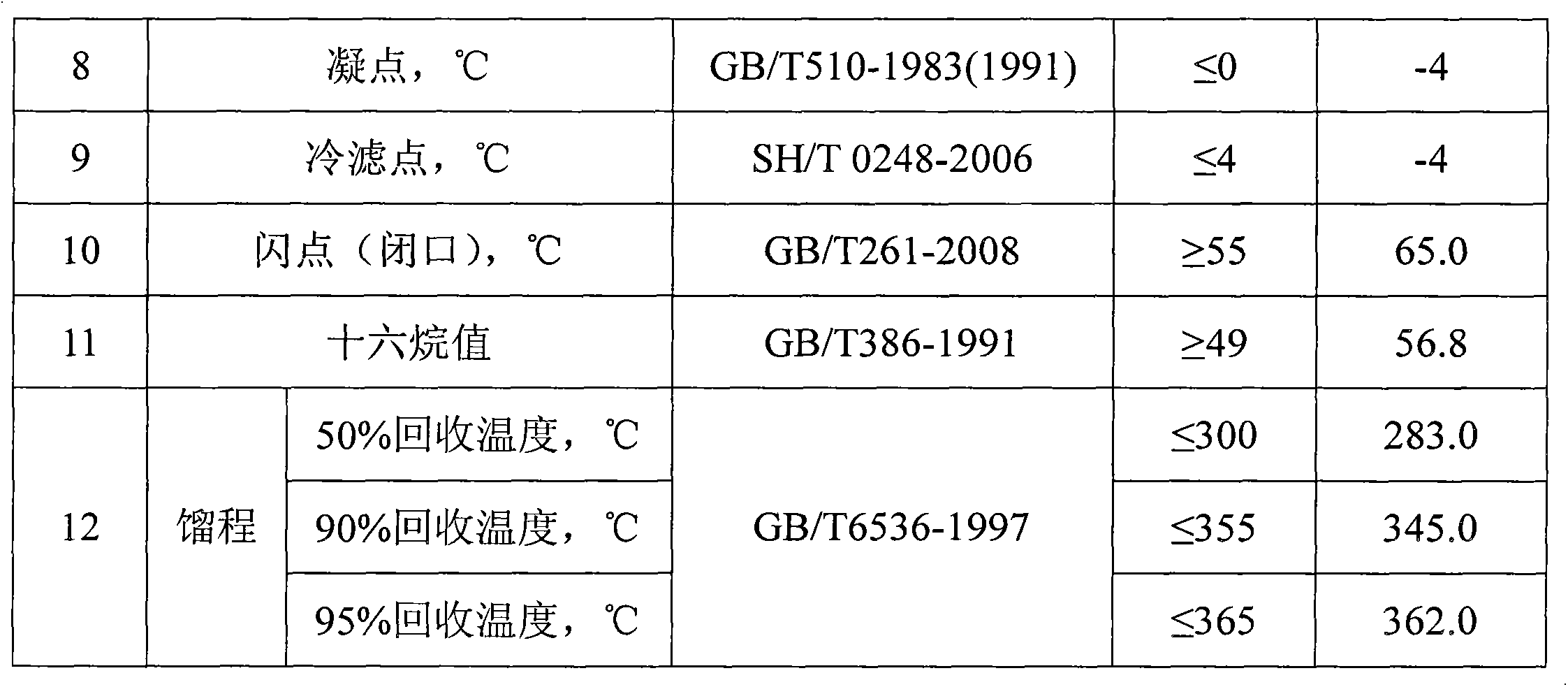

[0031] According to the national standard GB / T19147-2003 for vehicle diesel oil, the above-mentioned No. C alcohol ether biodiese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com