Lipophilic intaglio compound printing ink and preparation method thereof

An ink and ester-soluble technology, applied in the field of printing ink, can solve the problems of high solvent residue and strong odor, and achieve the effects of good resolubility, uniform particle size and low solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

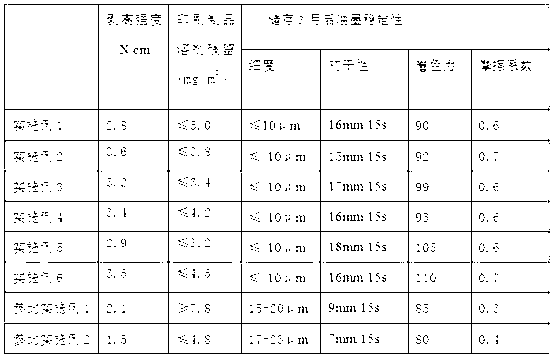

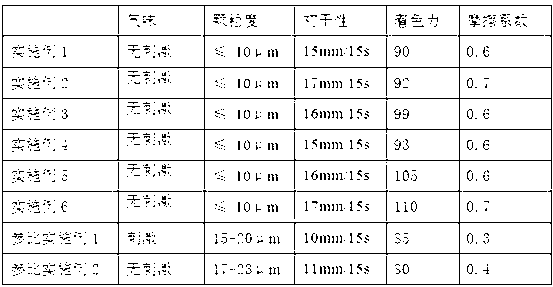

Examples

Embodiment 1

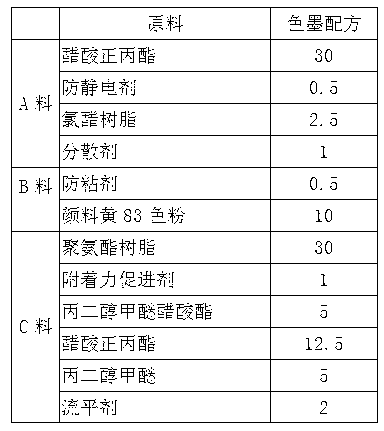

[0020] Embodiment 1 Ester-soluble polyurethane ink of the present invention

[0021]

[0022] The preparation method of the above-mentioned ester-soluble polyurethane ink is as follows: take n-propyl acetate, antistatic agent, vinyl chloride resin and dispersant and mix uniformly by weighing parts by weight of the prescription, add anti-sticking agent and toner to the mixture and disperse for 30 minutes. Turn over to the sand mill until the fineness is qualified, put into it polyurethane resin, adhesion promoter, propylene glycol methyl ether acetate, n-propyl acetate, propylene glycol methyl ether and leveling agent, and then disperse for 10 minutes to obtain the present invention. The ester-soluble polyurethane ink.

Embodiment 2

[0023] Embodiment 2 Ester-soluble polyurethane ink of the present invention

[0024]

[0025] The preparation method of the above-mentioned ester-soluble polyurethane ink is as follows: take n-propyl acetate, antistatic agent, vinyl chloride resin and dispersant and mix uniformly by weighing parts by weight of the prescription, add anti-sticking agent and toner to the mixture and disperse for 30 minutes. Turn over to the sand mill until the fineness is qualified, put into it polyurethane resin, adhesion promoter, propylene glycol methyl ether acetate, n-propyl acetate, propylene glycol methyl ether and leveling agent, and then disperse for 10 minutes to obtain the present invention. The ester-soluble polyurethane ink.

Embodiment 3

[0026] Embodiment 3 Ester-soluble polyurethane ink of the present invention

[0027]

[0028] The preparation method of the above-mentioned ester-soluble polyurethane ink is as follows: take n-propyl acetate, antistatic agent, vinyl chloride resin and dispersant and mix uniformly by weighing parts by weight of the prescription, add anti-sticking agent and toner to the mixture and disperse for 30 minutes. Turn over to the sand mill until the fineness is qualified, put into it polyurethane resin, adhesion promoter, propylene glycol methyl ether acetate, n-propyl acetate, propylene glycol methyl ether and leveling agent, and then disperse for 10 minutes to obtain the present invention. The ester-soluble polyurethane ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com