Method for preparing porous europium-manganese coordination polymer material and application thereof

A technology of coordination polymer and coordination water, which is applied in the field of combining inorganic chemistry and material chemistry, can solve problems such as consumption and multi-energy, and achieve the effects of simple process, good water stability and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Eu(NO 3 ) 3 ·6H 2 O and 4-hydroxy-2,6-pyridinedioic acid were mixed at a molar ratio of 1:3 and 3 mL of DEF was added, put into a polytetrafluoroethylene liner of a hydrothermal reactor, and reacted at 90 °C for 72 h. Get Eu(H 2 CAM) 3 ·5H 2 O; then Eu(H 2 CAM) 3 ·5H 2 O and MnCl 2 4H 2 O was mixed in a molar ratio of 1:3, added 5 mL of water, put it into the polytetrafluoroethylene liner of the hydrothermal reactor, and reacted at 120 °C for 72 h; after cooling down 1.0 °C / h until 30 °C, filter , washed with water to obtain colorless strip crystals. Yield calculated based on Eu was 36%.

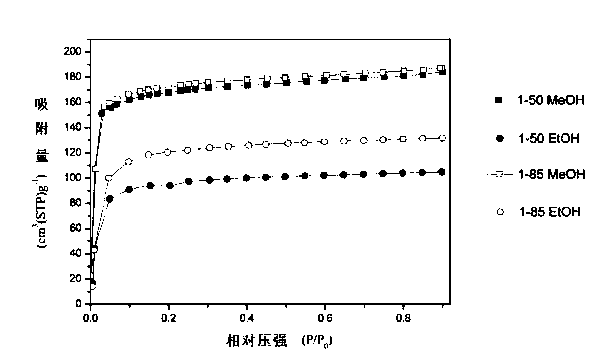

[0030] Characterization of porous europium-manganese coordination polymer materials:

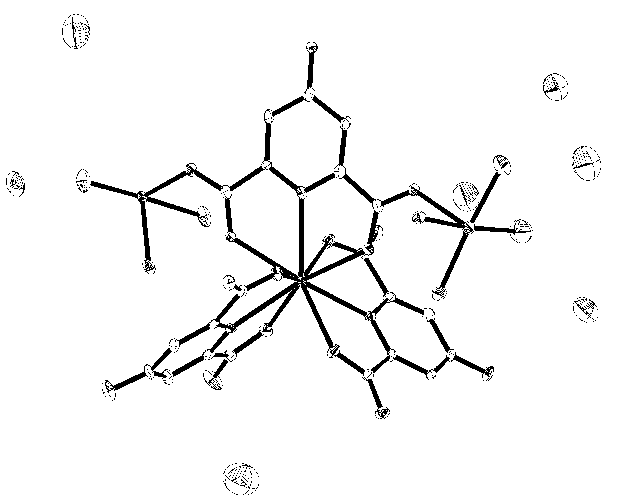

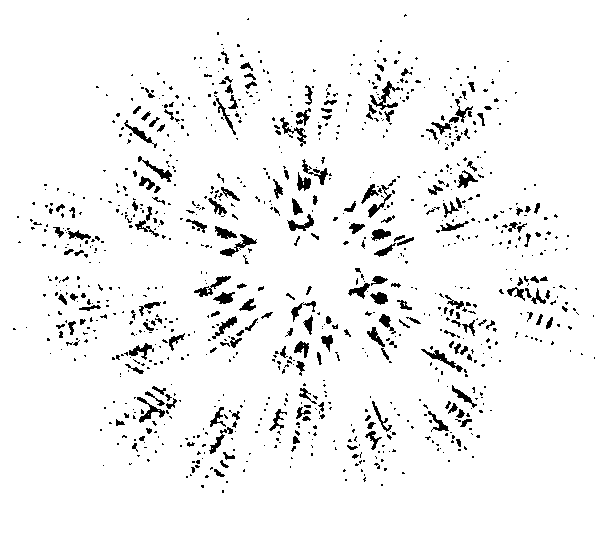

[0031] (1) Structure determination of porous europium-manganese coordination polymer materials

[0032] The crystal structure was determined by using a Supernova X-ray single crystal diffractometer, using Mo-Kα rays (λ= 0.71073 ?) monochromated by graphite as the incident radiation, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com