Method for manufacturing autoclaved aerated concrete heterogeneous wall components by separating mold cavity

An autoclaved aerated and heterogeneous technology, applied in the fields of manufacturing tools, chemical instruments and methods, clay preparation devices, etc., can solve the problems of different functions and complexities, save man-hours, simplify the construction process, and reduce materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

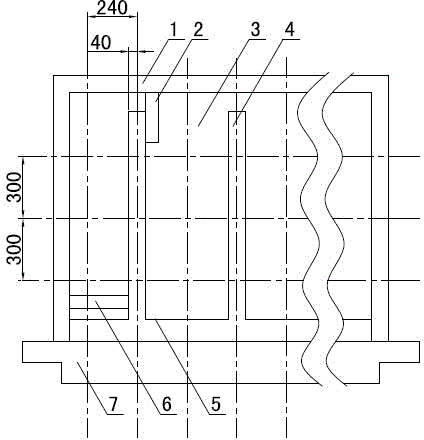

[0045] Such as figure 1 As shown, the mold frame body 1 and the mold side plate 7 with the same depth of 600mm together surround and form a rectangular inner cavity inside the mold, the horizontal positioning bar 6 is fixed on the left side of the mold frame body 1, and the vertical positioning bar 2 is fixed on the mold frame body 1 top side. In this embodiment, the partition assembly 5 is in the shape of a toothed wave in plan view. The partition component 5 divides the inner cavity into a body layer cultivation area 3 and a reinforcement layer incubation area 4 .

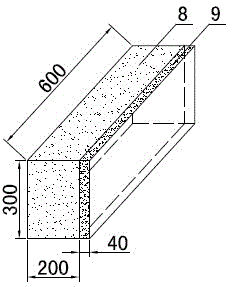

[0046]Set the vertical cutting and separation line of the embryo body on the vertical centerline of all the rectangular teeth of the partition assembly 5; the width of the narrow teeth is 80mm, and the interval between two adjacent narrow teeth is 400mm. After cutting, the body layer can be formed 8. The width is 200mm, the width of the reinforcing layer 9 is 40mm, and the total width is the block width dimensi...

Embodiment 2

[0050] In this embodiment, the above-mentioned non-homogeneous wall member manufacturing method is used to manufacture end face anchor point blocks.

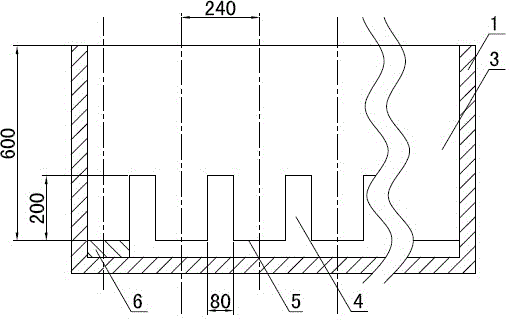

[0051] Such as image 3 As shown, the section of the partition assembly 5 is in the shape of a rectangular tooth wave, the width of the narrow teeth is 80 mm, the height is 200 mm, the width of the adjacent narrow teeth is 160 mm, and the cutting line is set on the vertical center line between the two narrow teeth superior. The upper part of the partition component 5 is the body layer cultivation area 3, and the lower part is the reinforcement layer cultivation area 4. Use the positioning strip to locate the corresponding position of the mold.

[0052] In this embodiment, slurry of B08-grade autoclaved aerated concrete and B04-grade autoclaved aerated concrete are poured in reinforcement layer cultivation area 4 and body layer cultivation area 3, respectively, until the slurry develops to semi-solid or initial solid state , r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com