Throttle valve device for each part of metal die in casting process

A metal mold and throttle valve technology, applied in the field of throttle valve devices, can solve the problems of shrinkage, shrinkage porosity, cracks, different cooling rates, etc., and achieve the effects of flexible use, convenient management, and strong field versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

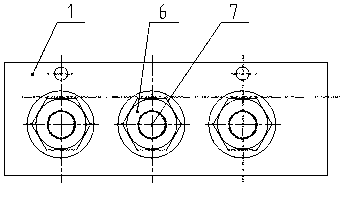

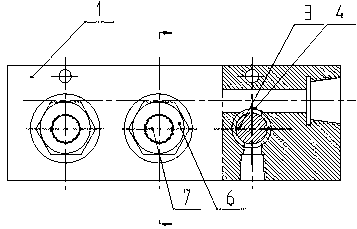

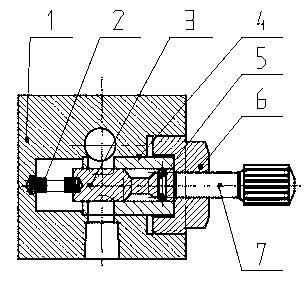

[0010] Such as figure 1 , figure 2 , image 3 shown. The present invention is composed of a valve body 1, a compression spring 2, a valve stem air volume adjusting head 3, a valve stem fixing block 4, an O-shaped sealing ring 5, a locking nut 6 and multiple sets of adjusting screw rods 7. The valve body 1 is provided with an air intake channel, and the air intake channel is located at the end of the valve body 1 and is provided with an air intake nozzle, which is convenient for externally connecting the cold air pipeline. In the valve body 1, three air outlet passages are arranged according to each position of the metal mold, and a gas regulating mechanism is arranged between each of the three air outlet passages and the air inlet passage. The gas regulating mechanism is composed of a compression spring 2, a valve stem gas volume regulating head 3, a valve stem fixing block 4, an O-ring 5, a lock nut 6 and multiple sets of adjusting screw rods 7. The number of air outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com