A car door anti-collision beam follow-up cutting device

A technology for automobile doors and cutting devices, which is applied in the direction of shearing devices, shearing machine accessories, metal processing equipment, etc., can solve the problems of affecting product quality, high equipment cost, and low production efficiency, and achieve low production and maintenance costs. The effect of stable and reliable operation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

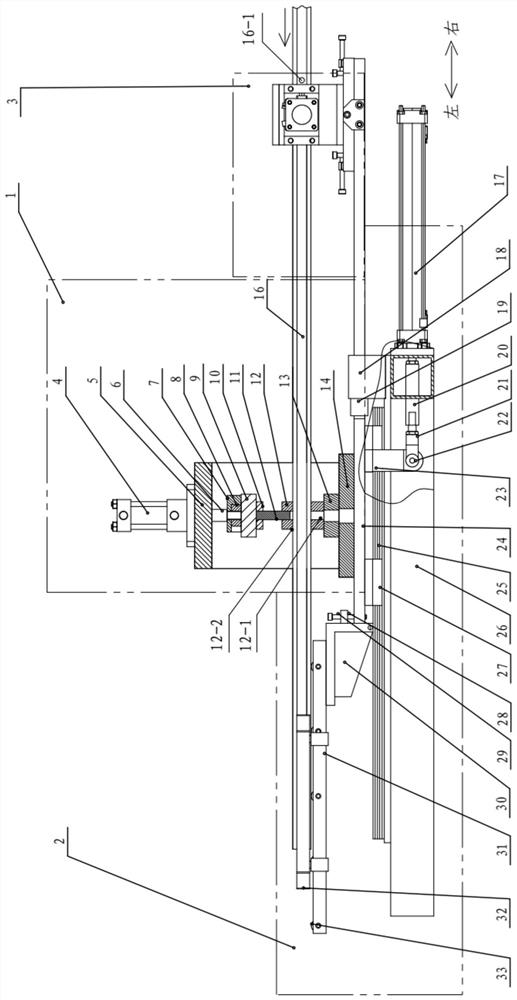

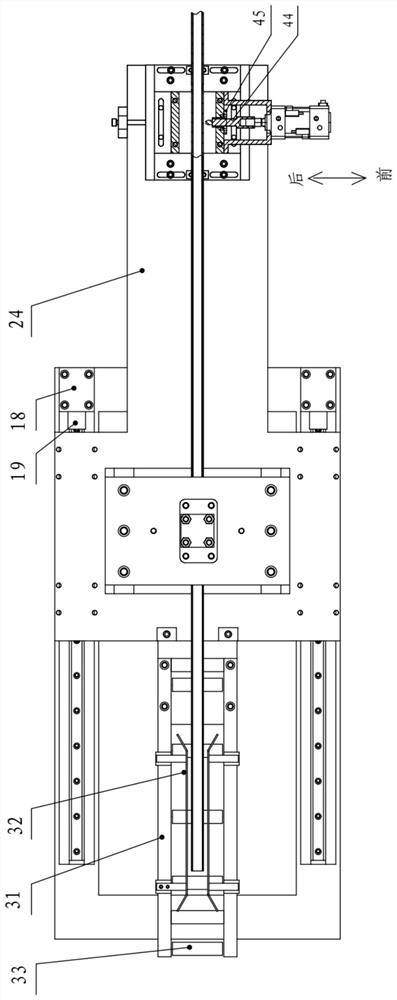

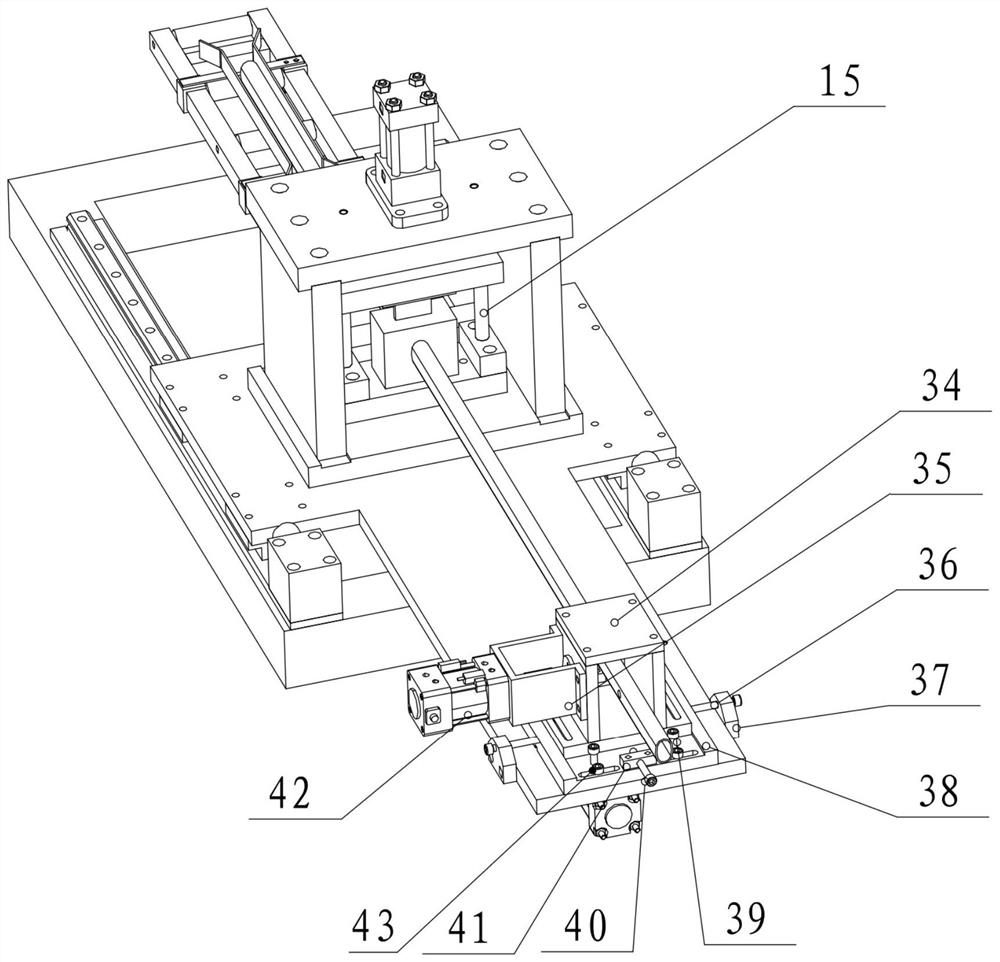

[0018] see figure 1 The device of the present invention includes a support 26 and a cutting mechanism 1, a follow-up mechanism 2, and a latch mechanism 3 arranged on the support. The above-mentioned mechanisms cooperate to realize the follow-up cutting of the automobile door anti-collision beam workpiece 16.

[0019] The cutting mechanism 1 is used for cutting off the anti-collision beam workpiece of the automobile door. see figure 1 , image 3 , The cutting mechanism cuts off the oil cylinder 4, cuts off the oil cylinder support frame 5, the upper template 9 and the lower template 13, the static knife 12 and the moving knife 11. The cutting oil cylinder support frame is fixed on the right side of the slide table, and the cutting oil cylinder is fixed on the top of the cutting oil cylinder support frame. Cut off the cylinder rod 6 and connect the upper template through the mold connection block 7 and the oil cylinder connection block 8, and the oil cylinder connection block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com