Adjustable pump valve self-locking antiskid differential

An anti-skid differential, adjustable technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of complex structure and shape of parts, easy wear of friction contact parts, insufficient power distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

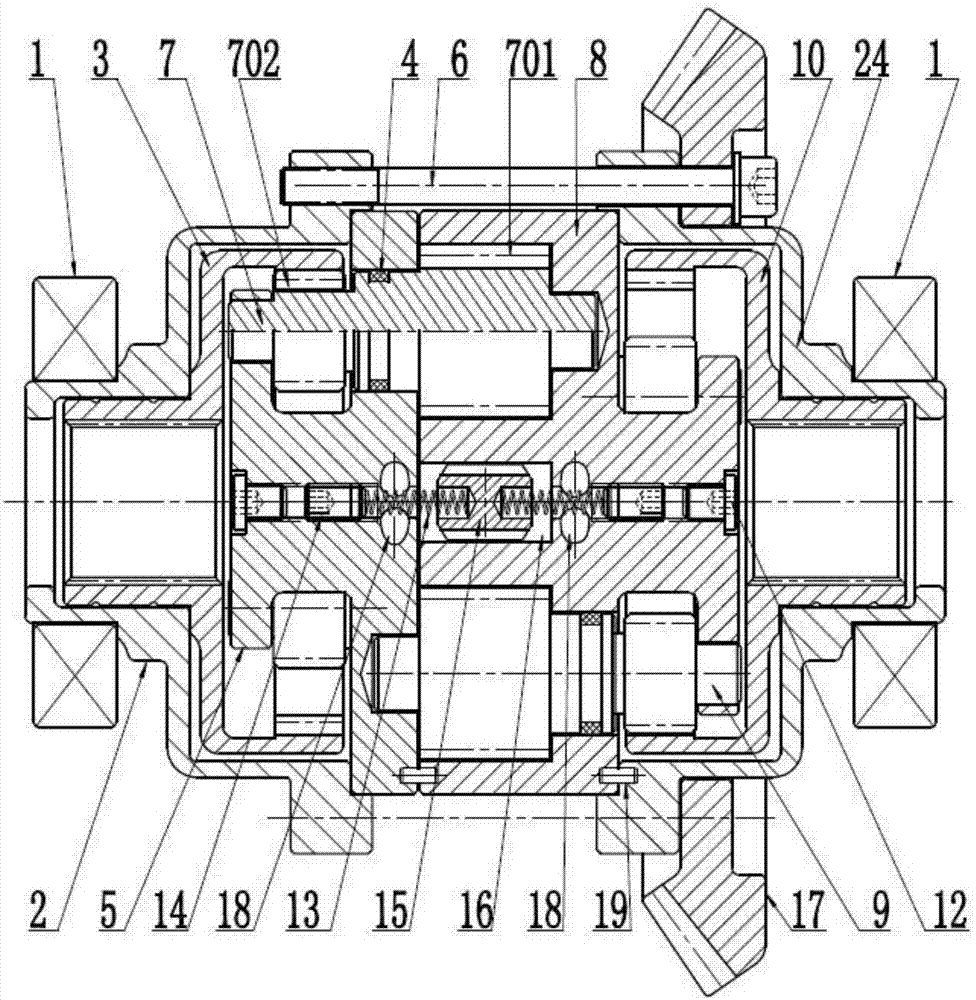

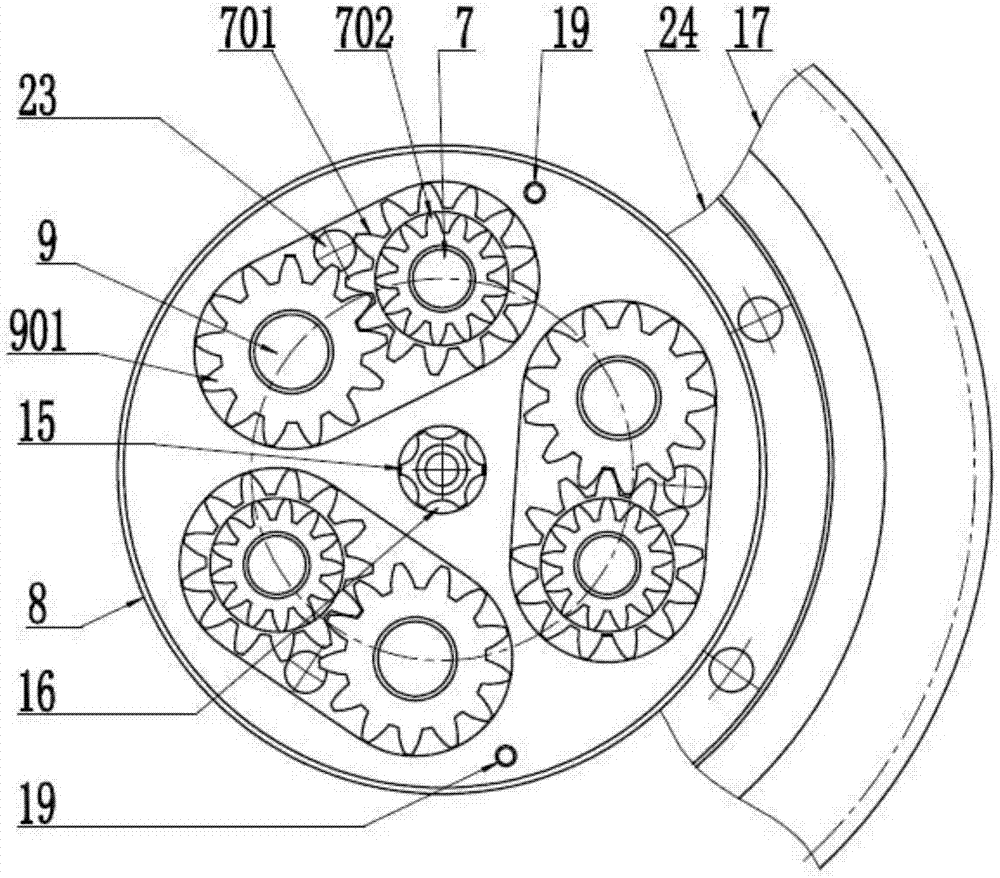

[0029] See attached Figure 1-3 , which shows one of the preferred and preferred structures of the adjustable pump-valve self-locking anti-slip differential involved in the present invention, which mainly consists of differential left case 2, differential right case 24, three groups A gear pump, a group of flow limiting valves, a left half-shaft ring gear 3, and a right half-shaft ring gear 10 are formed.

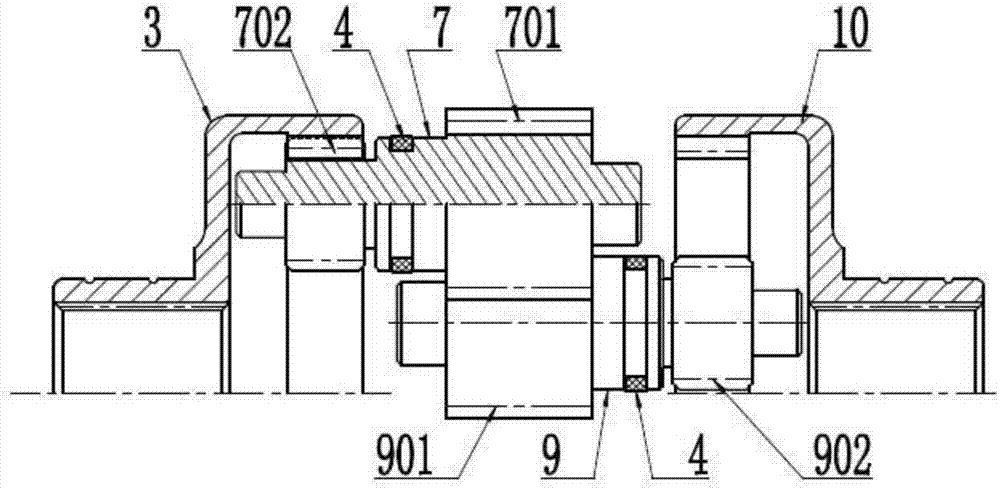

[0030] The pump body 8 of the above-mentioned three groups of gear pumps, the pump cover 5, the left and right shells 2, 24 of the differential, and the external large gear 17 are fastened by screws 6 and positioning pins 19, and are rotatably supported by the bearing 1; the above-mentioned three groups of gears pump, each group has a left drive gear shaft 7 and a right drive gear shaft 9; the left drive gear shaft 7 contains a left pump oil gear 701 and a left drive gear 702; the above right drive gear shaft 9 contains a right pump oil gear 901 and the right drive gear 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com