Spiral grape vine burying machine

A grape vine burying machine and screw-type technology, which is applied in the direction of soil preparation machinery, agricultural machinery and implements, etc., can solve the problems of poor operation quality, poor sealing, high operation cost, etc., to reduce operation cost, reduce power consumption, improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

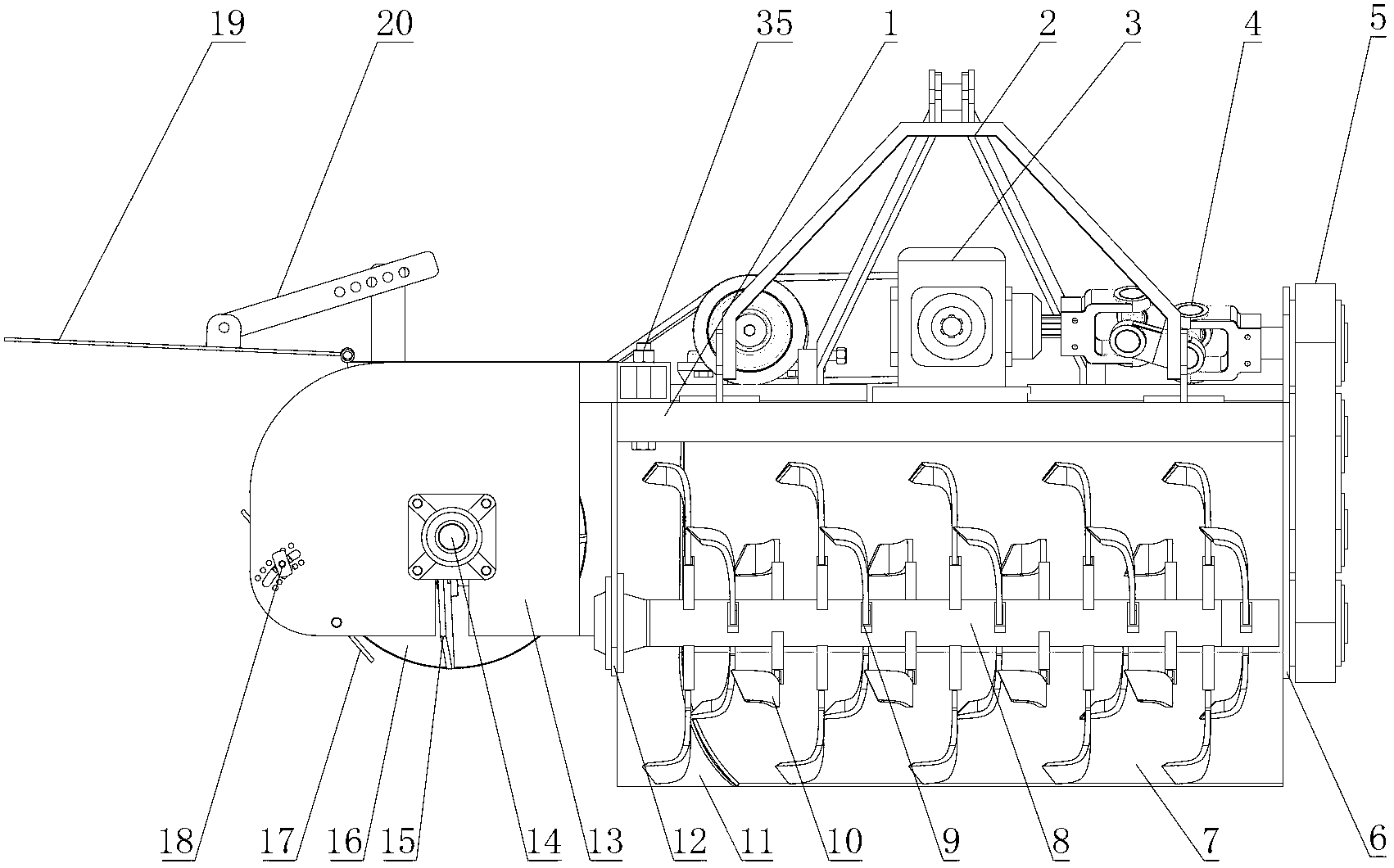

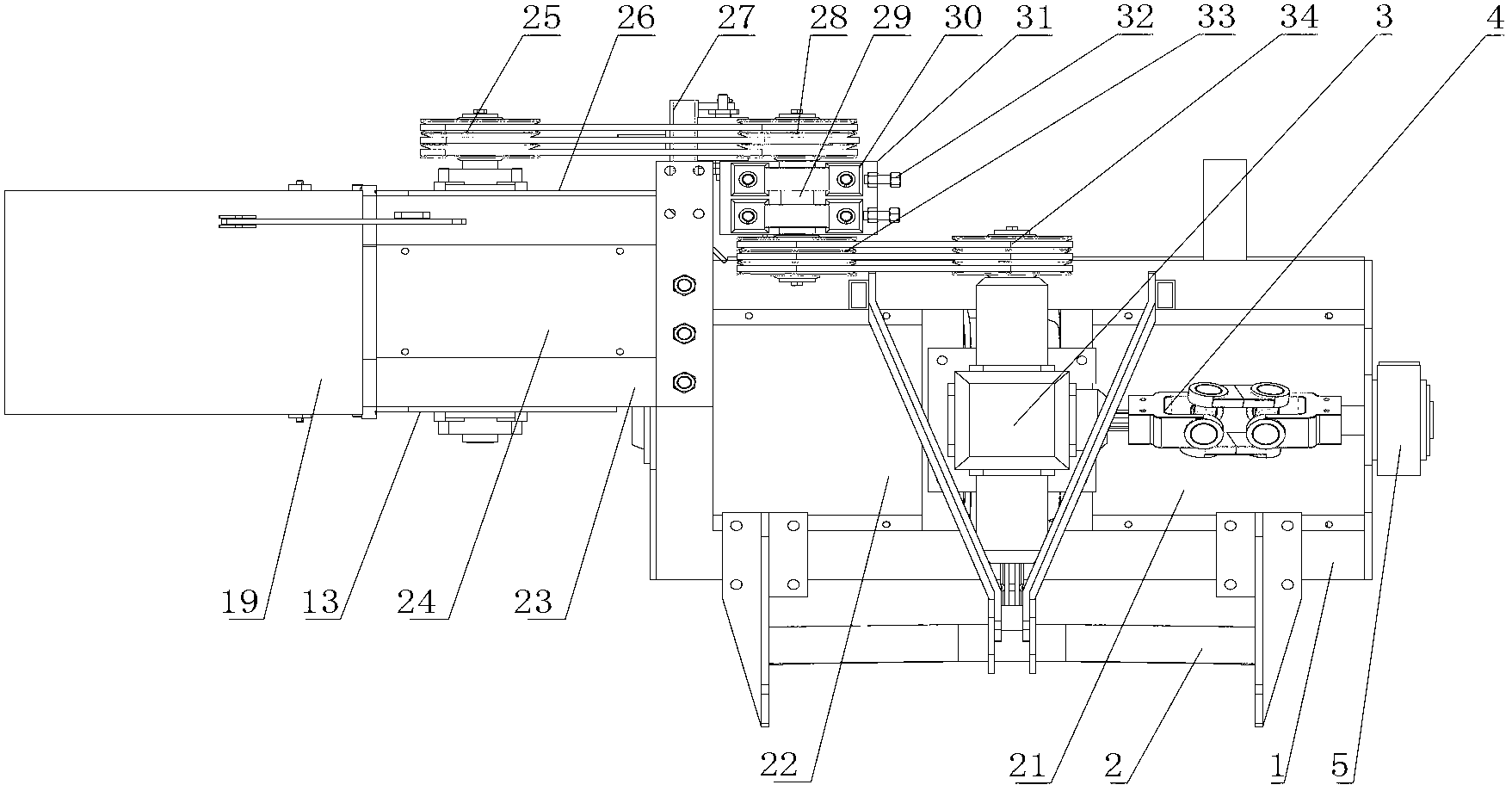

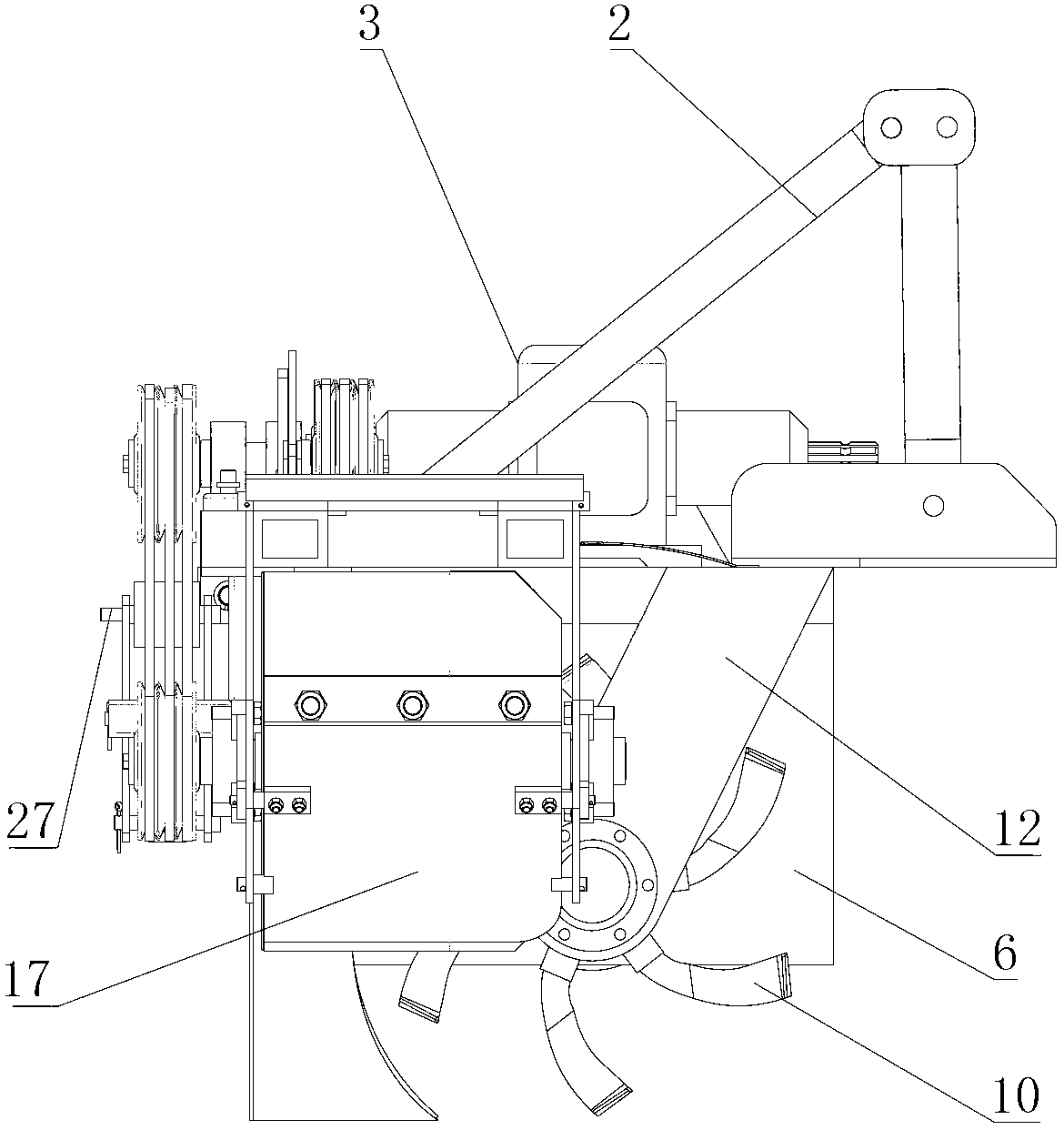

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0026] The power of the tractor matched with the spiral grape vine embedding machine of the present invention is in the range of 25kw to 35kw.

[0027] The three-point suspension frame 2 is suspended on the rear three-point suspension mechanism of the tractor, and the input shaft of the gear box 3 is connected with the power output shaft of the tractor through a universal joint coupling to complete the input of the power source.

[0028] Gear box 3 has two output shafts, which are distributed at 90 degrees. Wherein the output shaft of the gear box 3 perpendicular to the tractor walking direction is connected with the gear transmission box 5 installed on the left support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com